Silver-aluminum paste for front electrode of high-sheet-resistance N-type solar cell and preparation method of silver-aluminum paste

A technology of solar cells and front electrodes, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

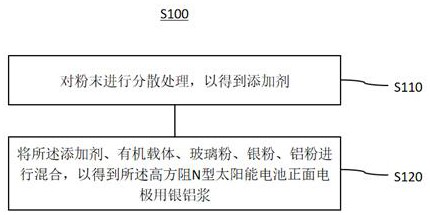

[0047] Another aspect of the present invention, there is provided a high square resistance N-type solar cell with the front electrode silver-aluminum paste preparation process S100, and includes the following steps S110-S120:

[0048] S110, the powder dispersing treatment, to obtain the additive.

[0049] Specifically, the powder, a dispersant and a solvent and stirring the mixed process to the surface of the powder coating dispersant, additive was obtained. The dispersant is adsorbed to the surface of the powder selected electric double layer is formed, from the dispersion.

[0050] Incidentally, the powder of the present example comprises at least one single-phase mixture, the single-phase mixture of silicon, aluminum, zinc, bismuth, antimony, at least one element of boron and zirconium. That is, silicon, zinc, bismuth, antimony, boron and zirconium as an additive element powder particles to particles comprising one or more components of single-phase mixture or more elements, or...

Embodiment 1

[0058] In this example a high square resistance N-type solar cell with the front electrode silver-aluminum paste production method, comprising the steps of:

[0059] Sl, a silicon-containing aluminum powder, a mixed solvent containing a pigment dispersant groups of the copolymer and diethylene glycol butyl ether and treated with stirring, to the surface of the powder coating dispersant, additive was obtained.

[0060] S2, the 0.01wt% additive, 8wt% organic vehicle, 5.43wt% of glass frit, 0.56wt% of aluminum powder, 86wt% silver powder were mixed to obtain a high sheet resistance N-type solar cell with the front electrode silver aluminum pulp.

[0061] As shown in Table 1, the photoelectric conversion efficiency EFF silver-aluminum paste obtained in this example was 23.26%, the open-circuit voltage Voc of 0.6955V, as the short-circuit current Isc 11.2771A, fill factor was 81.22%, the shunt resistor Rsh is 3728.1Ω, series resistance 0.00231Ω.

Embodiment 2

[0063] In this example a high square resistance N-type solar cell with the front electrode silver-aluminum paste production method, comprising the steps of:

[0064] Sl, the solvent mixture containing zinc, boron, aluminum powder, highly branched structure of the polyester dispersant and polyoxymethylene dimethyl ether and treated with stirring, to cover the surface of the powder dispersing agent, to give additive.

[0065] S2, the 0.07wt% additives, 5wt% of organic vehicle, 3wt% of glass frit, 1.93wt% of aluminum powder, 90wt% silver powder were mixed to obtain a high sheet resistance N-type solar cell with the front electrode silver paste aluminum .

[0066] As shown in Table 1, the photoelectric conversion efficiency EFF silver-aluminum paste obtained in this example was 23.37%, the open-circuit voltage Voc of 0.6971V, as the short-circuit current Isc 11.2769A, fill factor was 81.52%, the shunt resistor Rsh is 2891.3Ω, series resistance 0.00187Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com