De-molding-free heat preservation structure integrated plate and preparation method and construction method thereof

A formwork-free, thermal insulation board technology, applied in thermal insulation, structural elements, manufacturing tools, etc., can solve the problems of increasing the thickness of the leveling layer, large pre-stress, easy to misplace seams, etc., to shorten the construction period and cost, and reduce installation and connection. the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

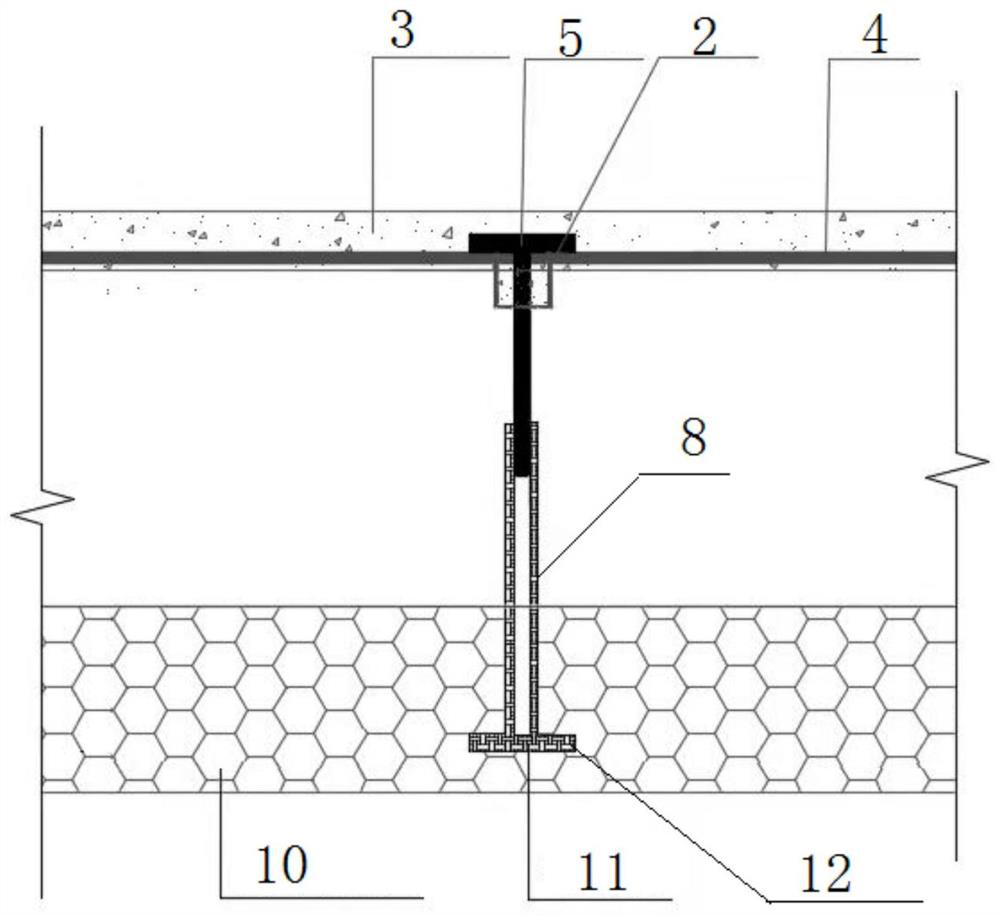

[0080] This embodiment provides a formwork-free insulation integrated board, such as figure 1 or 2, comprising: a first prefabricated structure and a second prefabricated structure, the first prefabricated structure comprising:

[0081] The mortar protective layer 3 is provided with several ribs 2 on one side, and the number of ribs in this embodiment is 2;

[0082] Steel wire mesh 4 is arranged inside the mortar protective layer 3;

[0083] Several connecting male parts 5, including the first anchor plate 6 and the first anchor rod 7, the first anchor plate 6 is located on the side of the steel wire mesh 4 away from the rib 2, the first anchor rod 7 penetrates to the mortar protection layer 3 external;

[0084] The second prefabricated structure includes a prefabricated thermal insulation module 10, and several connecting female parts 11 used in conjunction with the connecting male parts.

[0085] Optionally, the number of the ribs 2 can be 2-3, in this embodiment, the num...

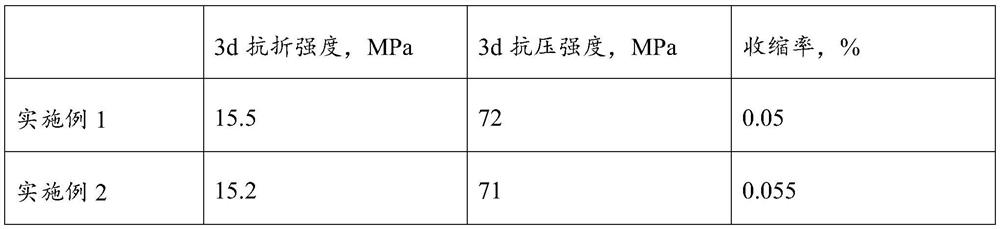

Embodiment 2

[0108] This embodiment provides a formwork-free thermal insulation integrated board, including: the structure and preparation method of the integrated board are the same as in Embodiment 1, the difference is that the composition of the powder for preparing the mortar protective layer is different, specifically, in In the present embodiment, the composition of described powder is:

[0109] 400kg of high belite anti-cracking double fast cement; 590kg of sand, including 110kg of 20-40 mesh sand, 320kg of 40-70 mesh sand, 160kg of 70-100 mesh sand; 4.1kg of admixture, including, water reducer ( FOX-C900 model) 2kg, retarder (sodium citrate) 1.2kg, lithium carbonate 0.5kg, Wenlun glue 0.1kg, expansion agent (402 expansion agent produced by Chongqing Yuyuan Building Materials Co., Ltd.) 0.3kg; Dispersible latex powder (5010N) 10kg.

Embodiment 3

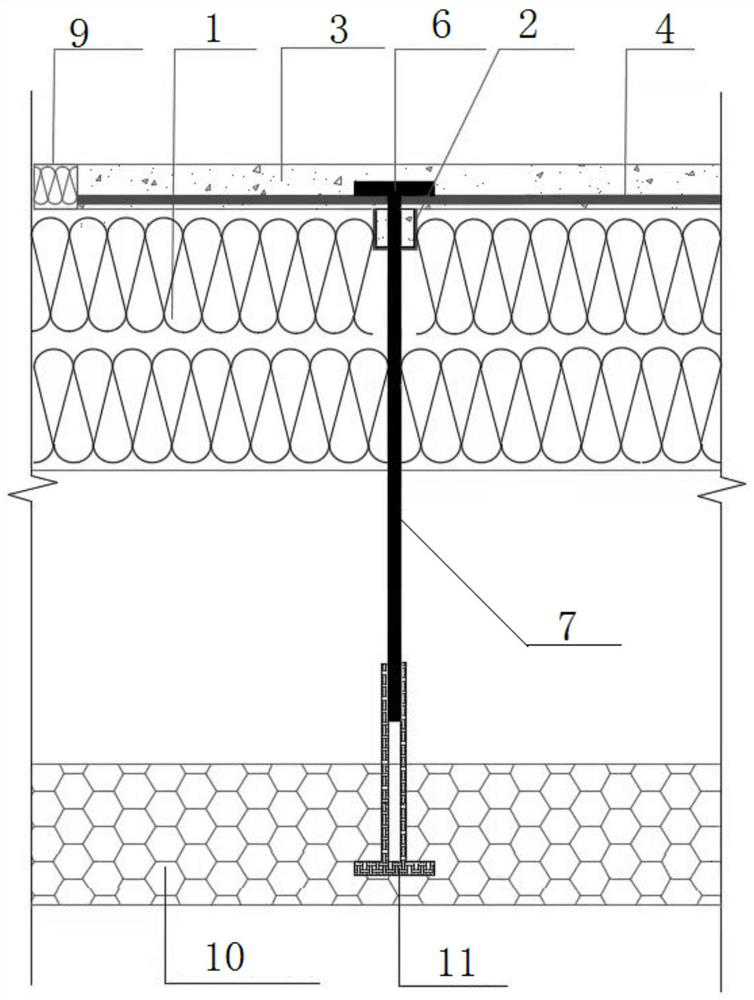

[0111] This embodiment provides a formwork-free thermal insulation integrated board. Compared with Embodiment 1, the difference is that the first prefabricated structure also includes a thermal insulation layer 1, and the thermal insulation layer 1 is provided with several grooves. Used to accommodate the rib 2 . The edge of the thermal insulation layer 1 is also provided with a transition zone 9, the width of the transition zone is 30mm, the number of ribs is 3, the height of the ribs is 35mm, and the width is 35mm; the number of the connectors is 6 pcs / square meter.

[0112] The material of the insulation layer can be rock wool board and its composite board, graphite polystyrene board, perlite board, graphite extruded board, extruded board, foam glass, etc. The thickness of the insulation layer can be determined according to the heat transfer coefficient of the wall. To adjust, in this embodiment the material of the insulation layer is a rock wool composite board with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com