Steel for in-situ nano reinforced and toughened crankshaft

A nano-reinforced and toughened technology, applied in the field of in-situ nano-reinforced and toughened steel for crankshafts, can solve the problems of insufficient quality stability and achieve the effects of improving macro segregation, no decrease in toughness, and reducing formation and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Study on Strengthening of Crankshaft Steel 42CrMoA by Vanadium

[0032] The trace element vanadium has the highest solubility and is one of the most commonly used and effective strengthening elements for microalloyed steels. The role of vanadium is to affect the structure and properties of steel by forming V (C, N). It is mainly precipitated in the ferrite at the austenite grain boundary, thereby refining the ferrite grains and improving the strength of the steel. Theoretical research shows that adding 0.10% vanadium in steel can increase the strength by more than 200MPa. The strengthening effect caused by the large amount of trace element V precipitated in ferrite is obvious. Compared with other microalloying methods, the steel containing V has a lower yield ratio. For the strong plastic fit of steel, V-containing microalloyed steel has unique product performance advantages.

[0033] (1) Chemical composition of 42CrMoA steel for engine crankshaft

[0034] Vanadium ...

Embodiment 2

[0050] In-situ nano-reinforced and toughened engine crankshaft steel

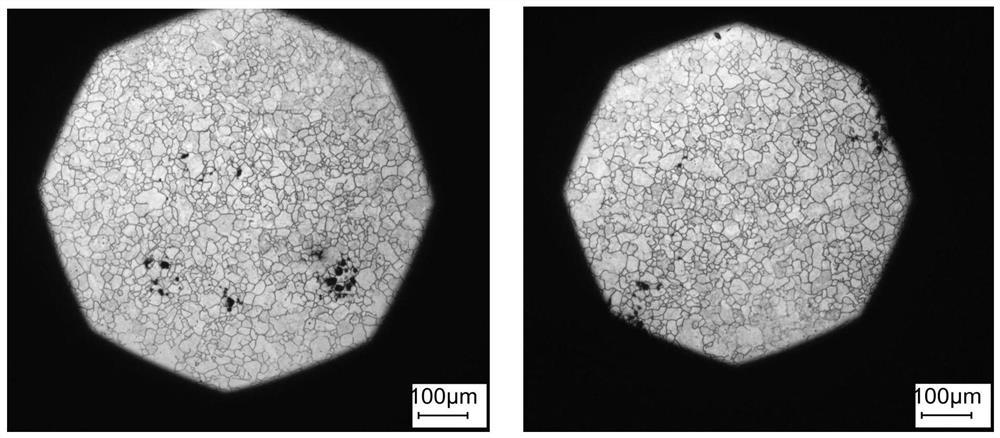

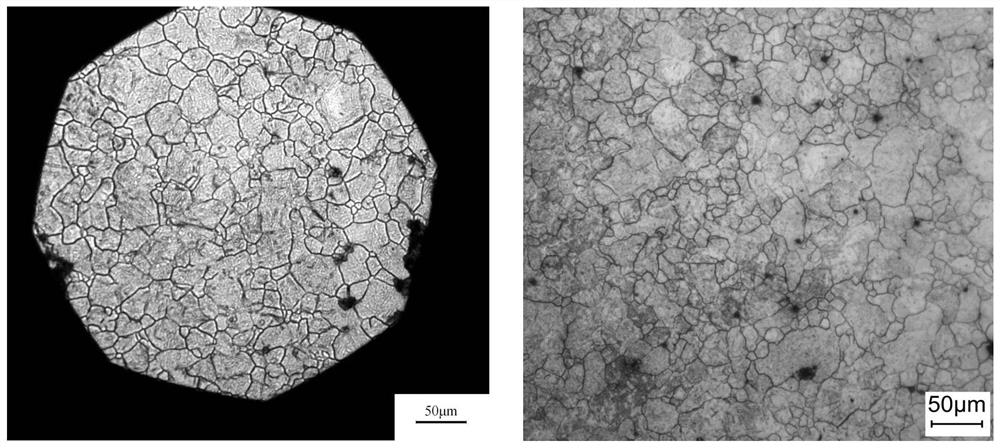

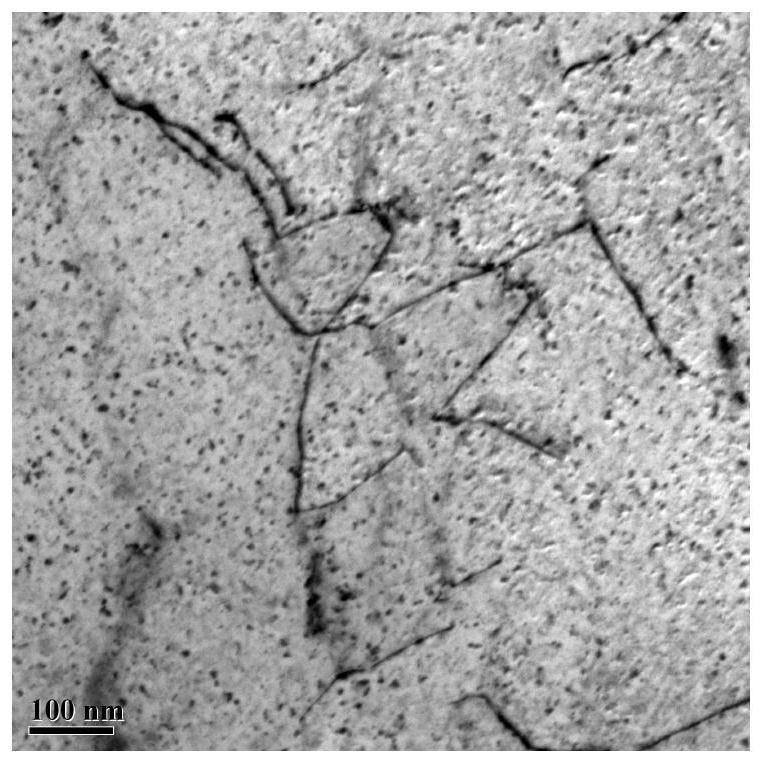

[0051] In-situ nanoparticles induce grain refinement, and a large number of nanoparticles are distributed inside the fine grains to form nano-microstructure and improve toughness; in-situ nanoparticles absorb solute atoms, refine grains, and provide diffusion channels to eliminate segregation , to alleviate the deterioration of brittle segregation relative to plasticity and toughness; use in-situ nanoparticles, fine grains and dislocations to interact to produce strain hardening, dissipate energy, delay material instability, and improve toughness at the same time. Strengthening mechanism see Figure 4 .

[0052] Feeding nanowires through the LF refining process, see Figure 5 , Figure 6 , for precipitation strengthening.

[0053] The molten steel in the converter reaches the LF furnace for refining before the temperature is not lower than 1540°C. The refining time is controlled at 50 minutes per furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com