SiC/SiC composite material high-density multilayer matrix and preparation method thereof

A composite material and matrix technology, which is applied in the field of composite material preparation, can solve the problems of crack energy consumption, crack deflection, single structure, etc., and achieve the effect of reducing open porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

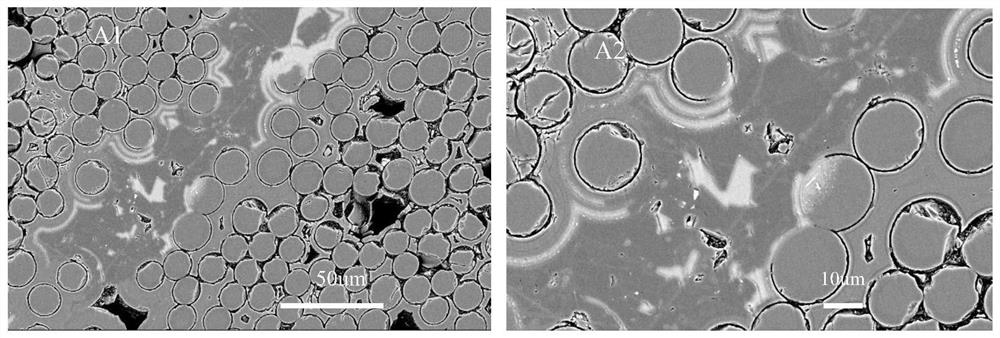

Image

Examples

preparation example Construction

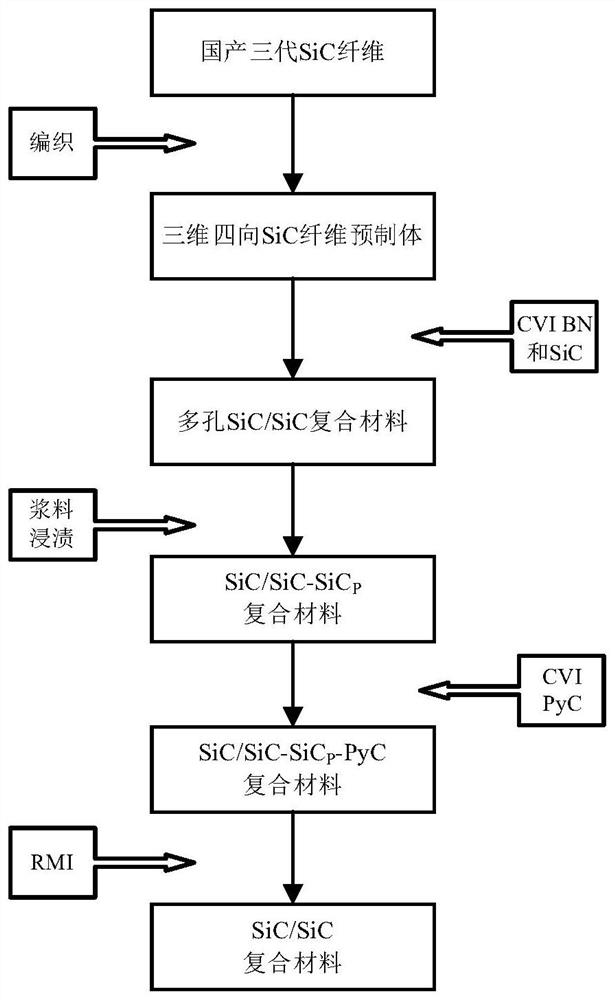

[0041] Step 1. Preparation of SiC / SiC preform:

[0042] In step 1.1, a boron nitride (BN) interface phase is prepared on the surface of the SiC fiber braided body, and the thickness of the interface phase is 300-500 nm.

[0043] Step 1.2 Prepare a certain volume fraction of the SiC matrix in the SiC fiber preform obtained in step 1.1 by using the CVI process. Using trichloromethylsilane (MTS) as the precursor, hydrogen as the carrier gas, and argon as the diluent gas, the flow ratio of the three is 1:5-50:2-20, the total pressure is 0.5-5kPa, and the deposition temperature is 873 ~1773K, the deposition time is about 600 hours. Thus, the porosity is 28-36%, and the density is 1.7-2.1g / cm 3 porous SiC / SiC composites for subsequent slurry impregnation.

[0044] Step 2. Configure 300-500nm SiC particle water-based slurry:

[0045] Step 2.1 Add SiC particles with a particle size of 300-500 nm and a volume fraction of 10 vol.% to HF acid, and stir magnetically at room temperatur...

Embodiment 1

[0065] Step 1. Preparation of SiC / SiC preform:

[0066] In step 1.1, a boron nitride (BN) interface phase is prepared on the surface of the SiC fiber braided body, and the thickness of the interface phase is 300-500 nm.

[0067] Step 1.2 Prepare a certain volume fraction of the SiC matrix in the SiC fiber preform obtained in step 1.1 by using the CVI process. Using trichloromethylsilane (MTS) as the precursor, hydrogen as the carrier gas, and argon as the diluent gas, the flow ratio of the three is 1:5-50:2-20, the total pressure is 0.5-5kPa, and the deposition temperature is 873 ~1773K, the deposition time is about 600 hours. Thus, the porosity is 28-36%, and the density is 1.7-2.1g / cm 3 porous SiC / SiC composites for subsequent slurry impregnation.

[0068] Step 2. Configure 300-500nm SiC particle water-based slurry:

[0069] Step 2.1 Add SiC particles with a particle size of 300-500 nm and a volume fraction of 10 vol.% to HF acid, and stir magnetically at room temperatur...

Embodiment 2

[0089] Step 1. Preparation of SiC / SiC preform:

[0090] In step 1.1, a boron nitride (BN) interface phase is prepared on the surface of the SiC fiber braided body, and the thickness of the interface phase is 300-500 nm.

[0091] Step 1.2 Prepare a certain volume fraction of the SiC matrix in the SiC fiber preform obtained in step 1.1 by using the CVI process. Using trichloromethylsilane (MTS) as the precursor, hydrogen as the carrier gas, and argon as the diluent gas, the flow ratio of the three is 1:5-50:2-20, the total pressure is 0.5-5kPa, and the deposition temperature is 873 ~1773K, the deposition time is about 600 hours. Thus, the porosity is 28-36%, and the density is 1.7-2.1g / cm 3 porous SiC / SiC composites for subsequent slurry impregnation.

[0092] Step 2. Configure 300-500nm SiC particle water-based slurry:

[0093] Step 2.1 Add SiC particles with a particle size of 300-500 nm and a volume fraction of 10 vol.% to HF acid, and stir magnetically at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com