Bio-based UV light-induced viscosity-reducing pressure-sensitive adhesive and preparation method thereof

A bio-based, light-induced technology, applied in the field of pressure-sensitive adhesives, can solve problems such as harmful, environmentally toxic, and inconsistent with the development trend of the ecological environment, and achieve a wide range of application prospects, easy to peel, and achieve the effect of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

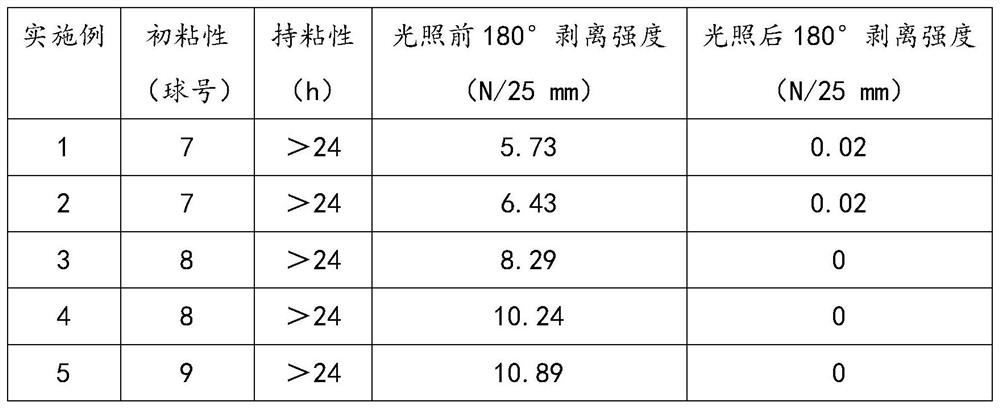

Examples

Embodiment 1

[0034] In the first step, the following raw materials are added to a four-necked bottle equipped with a thermometer, a spherical condenser, a dropping funnel, and a stirrer: 19.02 g of oleic acid, 14.26 g of lauryl methacrylate, and 2.84 g of tetrahydrofurfuryl methacrylate. g, 5.69 g of itaconic acid, 5.69 g of N-methylolacrylamide and 50.47 g of ethyl acetate. Under stirring, the solution was heated to 75° C., and then a solution of ethyl acetate (21.61 g) dissolved with dibenzoyl peroxide (0.48 g) was slowly added dropwise to the monomer solution in the flask through a dropping funnel. The mixture was stirred at 75 °C for 8 h to obtain a first viscous solution.

[0035]In the second step, 4-dimethylaminopyridine (0.68g), 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (1.08g) was added to the first step obtained One viscous solution was stirred at room temperature for 24 h to obtain a second viscous solution.

[0036] In the third step, rosin (71.28g) was disso...

Embodiment 2

[0041] In the first step, the following raw materials are added to a four-necked bottle equipped with a thermometer, a spherical condenser, a dropping funnel, and a stirrer: 25.36 g of oleic acid, 19.01 g of lauryl methacrylate, and 3.79 g of tetrahydrofurfuryl methacrylate. g, 7.58 g of itaconic acid, 7.58 g of N-methylolacrylamide, 19.22 g of toluene and 48.05 g of butyl acetate. Under stirring, the solution was heated to 80° C., and then a solution of butyl acetate (28.83 g) dissolved with azobisisobutyronitrile (0.32 g) and dibenzoyl peroxide (0.32 g) was slowly dropped through the dropping funnel. Add to the monomer solution in the flask. The mixture was stirred at 80 °C for 8 h to obtain a first viscous solution.

[0042] In the second step, 4-dimethylaminopyridine (0.91g), 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (1.44g) was added to the first step obtained One viscous solution was stirred at room temperature for 24 h to obtain a second viscous solut...

Embodiment 3

[0048] In the first step, the following raw materials are added to a four-necked bottle equipped with a thermometer, a spherical condenser, a dropping funnel, and an agitator: 31.70 g of oleic acid, 23.76 g of lauryl methacrylate, and 4.74 g of tetrahydrofurfuryl methacrylate. g, 9.48 g of itaconic acid, 9.48 g of N-methylolacrylamide, 24.03 g of toluene and 60.08 g of butyl acetate. Under stirring, the solution was heated to 80° C., and then a solution of ethyl acetate (36.02 g) dissolved in azobisisoheptanonitrile (0.8 g) was slowly added dropwise to the monomer solution in the flask through the dropping funnel. The mixture was stirred at 80 °C for 8 h to obtain a first viscous solution.

[0049] In the second step, 4-dimethylaminopyridine (1.13g), 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (1.80g) was added to the first step obtained in the first step One viscous solution was stirred at room temperature for 24 h to obtain a second viscous solution.

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| 180°peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com