Acrylate pressure-sensitive adhesive, preparation method thereof and protective film

An acrylate and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve the problems of high energy consumption, accelerated product aging, VOC emission, etc., and achieve the effects of low cost, high reducibility and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

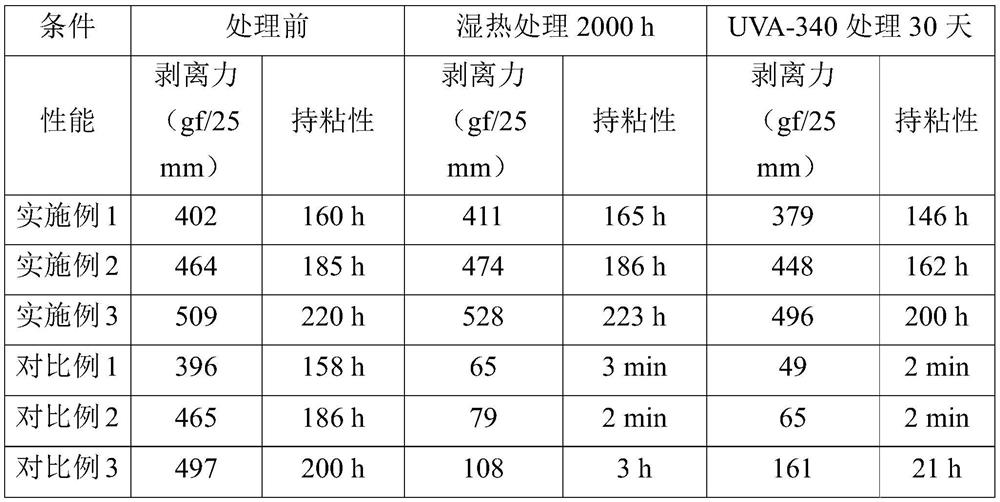

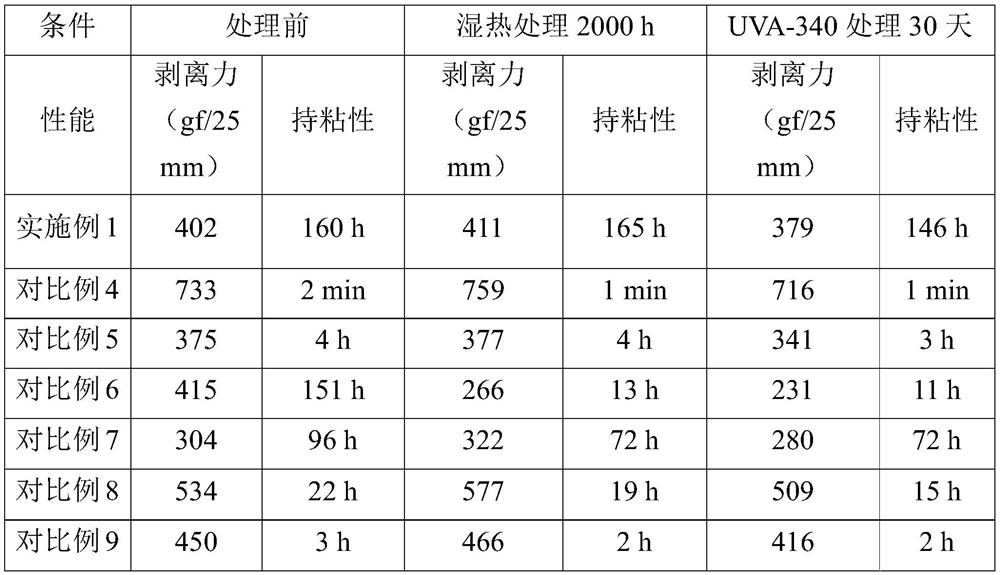

Examples

Embodiment 1

[0021] The present embodiment provides a kind of preparation method of acrylate pressure-sensitive adhesive, and it comprises the steps:

[0022] (10) prepare raw materials by following composition and parts by weight:

[0023] A: 60 parts of acrylic soft monomer (isooctyl acrylate)

[0024] Acrylic hard monomer 10 parts (methyl methacrylate)

[0025] Acrylic acid functional monomer 0.5 parts (acrylic acid, maleic acid and hydroxyethyl acrylate)

[0026] 0.3 parts of the first photoinitiator (benzoin ether)

[0027] B: 10 parts of diluted monomer (hydroxyethyl methacrylate, hydroxypropyl acrylate and acryloyl morpholine)

[0028] 0.5 parts of the second photoinitiator (2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-acetone and phenylbis(2,4,6-trimethylbenzyl acyl)phosphine oxide)

[0029] C: 0.5 parts of 4-hexyl-4H-dithieno[3,2-b:2,3-d]pyrrole

[0030] (11) Add each component in component A to the reaction kettle, mix evenly, and irradiate for 150s with an ultraviolet li...

Embodiment 2

[0034] The present embodiment provides a kind of preparation method of acrylate pressure-sensitive adhesive, and it comprises the steps:

[0035] (20) prepare raw materials by following composition and parts by weight:

[0036] A: 85 parts of acrylic soft monomer (isooctyl acrylate and n-butyl acrylate)

[0037] Acrylic hard monomer 25 parts (styrene and vinyl acetate)

[0038] Acrylic functional monomer 2 parts (hydroxypropyl acrylate)

[0039] 1.5 parts of the first photoinitiator (2-hydroxyl-2-methyl-1-phenyl-1-propanone and 2-hydroxyl-cyclohexyl-benzophenone)

[0040] B: 50 parts of diluted monomer (tetrahydrofuran acrylate and cyclotrimethylolpropane methylal acrylate)

[0041] 1.5 parts of the second photoinitiator (1-hydroxyl-cyclohexyl-benzophenone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 2-methyl-1-(4- Methylthiophenyl)-2-morpholine-1-propanone)

[0042]C: 2 parts of 4-hexyl-4H-dithieno[3,2-b:2,3-d]pyrrole

[0043] (21) Add each component in component...

Embodiment 3

[0047] The present embodiment provides a kind of preparation method of acrylate pressure-sensitive adhesive, and it comprises the steps:

[0048] (30) prepare raw materials by following composition and parts by weight:

[0049] A: 70 parts of acrylic soft monomer (ethyl acrylate)

[0050] Acrylic hard monomer 15 parts (vinyl acetate, acrylonitrile and isobornyl methacrylate)

[0051] Acrylic functional monomer 1 part (hydroxyethyl methacrylate and glycidyl methacrylate)

[0052] 1 part of the first photoinitiator (3-hydroxy-cyclohexyl-benzophenone)

[0053] B: Dilute monomer 25 parts (trimethylolpropane triacrylate)

[0054] 0.8 part of second photoinitiator (1-hydroxyl-cyclohexyl-benzophenone)

[0055] C: 1 part of 4-phenyl-4H-dithieno[3,2-b:2,3-d]pyrrole

[0056] (31) Add each component in component A to the reaction kettle, mix evenly, and irradiate with an ultraviolet light source with a wavelength of 365nm for 300s to obtain an acrylate prepolymer;

[0057] (32) Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com