Wear-resistant flexible diffusion film and preparation process thereof

A preparation process and diffusion film technology, applied in the field of optical films, can solve problems such as difficulty, light efficiency, light diffusivity, color rendering constraints, etc., to prevent drift, facilitate flexibility, and improve wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

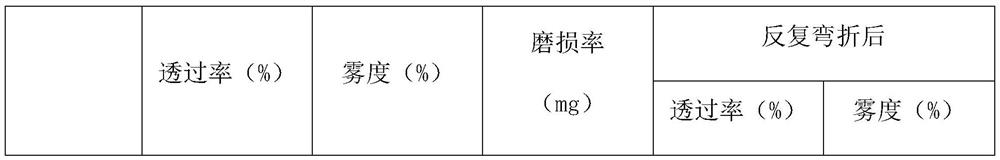

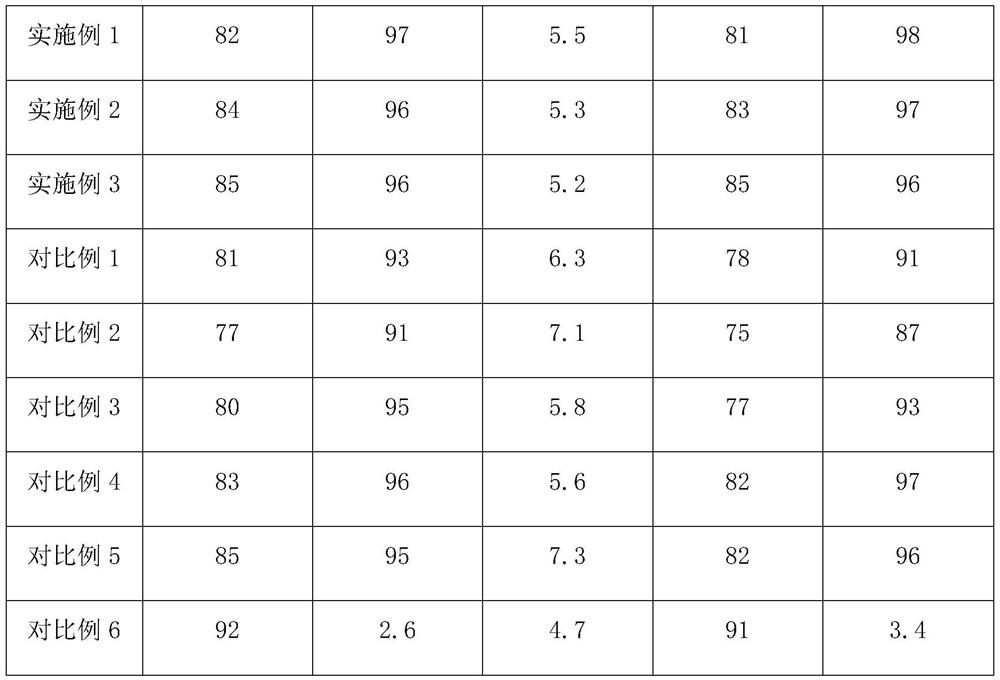

Examples

Embodiment 1

[0041] (1) Preparation of diffusion particles:

[0042] Mix tetraethyl orthosilicate and ammonia water, add absolute ethanol, stir at room temperature, react for 5 hours, centrifuge, take the precipitate and wash it 3 times with ethanol, dry to obtain silica microspheres;

[0043] Take silicon dioxide microspheres and use a metal vapor vacuum arc ion implanter to implant zinc ions. The process is: accelerating voltage 27kV, implantation volume 1.2×10 17 / cm 2 , zinc ion energy 87keV, beam current density 2.0μA / cm 2 , annealing, the process is: oxygen atmosphere, annealing temperature 600 ° C, time 1h, prepared modified silica microspheres;

[0044] Take the modified silica microspheres and add deionized water, ultrasonically disperse for 50 minutes, add urea and sodium tartrate, stir, add vinyltrimethoxysilane, adjust the pH of the system to 4, stir for 50 minutes, and react at a constant temperature of 175°C for 3 hours. Cool, centrifuge, wash the precipitate with water th...

Embodiment 2

[0055] (1) Preparation of diffusion particles:

[0056] Mix tetraethyl orthosilicate and ammonia water, add absolute ethanol, stir at room temperature, react for 5.5 hours, centrifuge, take the precipitate and wash it 4 times with ethanol, dry to obtain silica microspheres;

[0057] Take silicon dioxide microspheres and use a metal vapor vacuum arc ion implanter to implant zinc ions. The process is: accelerating voltage 28kV, implantation volume 1.5×10 17 / cm 2 , zinc ion energy 107keV, beam current density 4.5μA / cm 2 , annealing, the process is: oxygen atmosphere, annealing temperature 800 ℃, time 4h, prepared modified silica microspheres;

[0058] Take the modified silica microspheres and add deionized water, ultrasonically disperse for 65 minutes, add urea and sodium tartrate, stir, add vinyltrimethoxysilane, adjust the pH of the system to 3.5, stir for 65 minutes, and react at a constant temperature of 180°C for 3.5 hours , cooled, centrifuged, washed the precipitate wi...

Embodiment 3

[0069] (1) Preparation of diffusion particles:

[0070] Mix tetraethyl orthosilicate and ammonia water, add absolute ethanol, stir at room temperature, react for 6 hours, centrifuge, take the precipitate and wash it 5 times with ethanol, dry to obtain silica microspheres;

[0071] Take silicon dioxide microspheres and use a metal vapor vacuum arc ion implanter to implant zinc ions. The process is: accelerating voltage 30kV, implantation volume 1.8×10 17 / cm 2 , Zinc ion energy 140keV, beam current density 7.0μA / cm 2 , annealing, the process is: oxygen atmosphere, annealing temperature 900 ° C, time 2h, prepared modified silica microspheres;

[0072] Take the modified silica microspheres and add deionized water, ultrasonically disperse for 80 minutes, add urea and sodium tartrate, stir, add vinyltrimethoxysilane, adjust the pH of the system to 3, stir for 80 minutes, and react at a constant temperature of 185°C for 4 hours. Cool, centrifuge, wash the precipitate with water 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com