Grinding medium and preparation method thereof

A technology of grinding media and raw materials, which is applied in the field of grinding media and its preparation, can solve the problems of limited grinding effect, insufficient buffering, and difficulty in cooling down, so as to reduce abnormal grain growth, increase impact resistance, and ensure impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

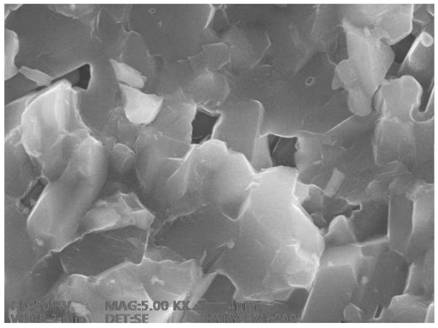

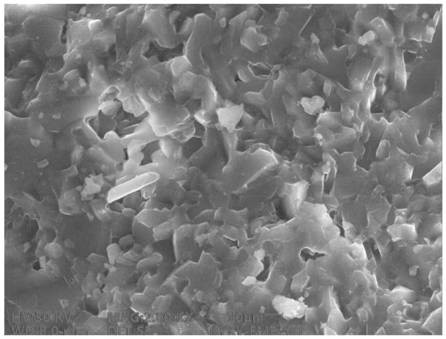

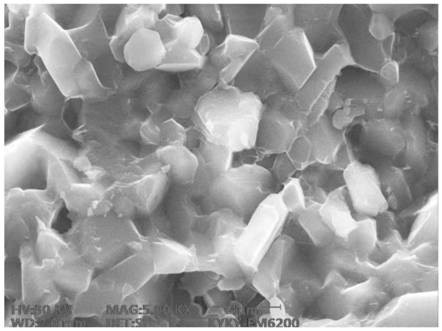

Image

Examples

Embodiment 2

[0046] Embodiment 2 and embodiment 3 disclose the preparation method of grinding medium of the present invention, wherein, the specific preparation process of embodiment 2 is:

[0047] 93% alumina powder, 0.5% calcined talc, 1.0% dolomite, 2.5% kaolin, 0.5% yttrium oxide, 0.5% lanthanum oxide and 1.0% barium carbonate. Add it into a grinder for grinding, the grinding time is 30h, then add 0.5% plasticizer and 0.5% dispersant, and mix to obtain a mixed slurry; dry the above mixed slurry to obtain a granulated powder , and then the isostatic pressing of the powdered granules can be carried out by using a bag-type rubber mold for isostatic pressing (adhesives can be added as required during the isostatic pressing) to obtain a green body, and the green body is subjected to high temperature Sintering to finally obtain grinding media.

[0048] Among them, the equipment used in the dry pulverization process can be a centrifugal spray granulation tower, and a 2500-type centrifugal sp...

Embodiment 3

[0050] The concrete preparation process of embodiment 3 is:

[0051] 95% alumina powder, 0.5% calcined talc, 1.0% dolomite, 2.0% kaolin, 0.3% yttrium oxide, 0.3% lanthanum oxide and 0.5% barium carbonate. Add it into a grinder for grinding, the grinding time is 36 hours, then add 0.2% plasticizer and 0.2% dispersant, and mix to obtain a mixed slurry; dry the above mixed slurry to obtain a granulated powder , and then the isostatic pressing of the powdered granules can be carried out by using a bag-type rubber mold for isostatic pressing (adhesives can be added as required during the isostatic pressing) to obtain a green body, and the green body is subjected to high temperature Sintering to finally obtain grinding media.

[0052] Wherein, the equipment adopted in the dry pulverization process can be a centrifugal spray granulation tower, for example, a 2500 type centrifugal spray granulation tower can be selected, the centrifugal disk speed of the centrifugal spray granulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com