A kind of super duplex stainless steel self-protected flux-cored welding wire and preparation method thereof

A technology of duplex stainless steel and flux-cored wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of two-phase ratio imbalance, harmful phase precipitation, etc., to improve corrosion resistance, increase diffusion path, weld seam The effect of tissue cleansing and densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

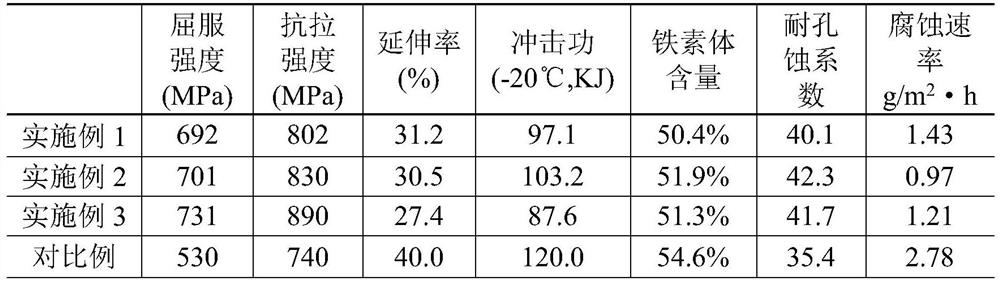

Examples

Embodiment 1

[0034] A super duplex stainless steel self-protected flux-cored welding wire adopts SUS430 steel strip as the outer skin, the size of the steel strip is 0.9×14mm, the filling rate of the flux-cored powder in the steel strip is 18.0%, and the diameter of the welding wire is 1.2mm. According to the total mass percentage of 100%, the chemical composition of the steel strip is: Cr 16.4%, Mo 2.5%, Mn 0.34%, Si 0.27%, Ni 0.14%, and the rest are iron; the core powder is alloy powder, chemical Composition: Cr 5.0%, Ni 2.0%, V 0.5%, N 0.1%, Fe 3 O 4 -Al 2 O 3 -Li 2 CO 3 4.0%, CaS 0.5%, ZrO 2 0.2%, Al-Mg 1.0%, Ti 0.5%, and the rest is iron.

[0035] The average particle size of the drug core powder is 100-150 μm, and the nano-nucleating agents CaS, ZrO 2 The particle size is 50-80nm, and the purity is 99.9%.

[0036] The preparation method of the super duplex stainless steel self-protected flux-cored welding wire of the present embodiment includes the following specific steps: ...

Embodiment 2

[0046] A super duplex stainless steel self-protected flux-cored welding wire adopts SUS430 steel strip as the outer skin, the size of the steel strip is 0.9×14mm, the filling rate of the flux-cored powder in the steel strip is 19.0%, and the diameter of the welding wire is 1.2mm. According to the total mass percentage of 100%, the chemical composition of the steel strip is: Cr 16.0%, Mo 2.0%, Mn 0.30%, Si 0.25%, Ni 0.10%, and the rest are iron; the core powder is alloy powder, chemical Composition: Cr 6.0%, Ni 3.0%, V 0.5%, N 0.15%, Fe 3 O 4 -Al 2 O 3 -Li 2 CO 3 5.0%, CaS 0.6%, ZrO 2 0.3%, Al-Mg 2.0%, Ti 1.0%, and the rest is iron.

[0047] The average particle size of the drug core powder is 100-150 μm, and the nano-nucleating agents CaS, ZrO 2 The particle size is 50-80nm, and the purity is 99.9%.

[0048] The preparation method of the super duplex stainless steel self-protected flux-cored welding wire of the present embodiment includes the following specific steps: ...

Embodiment 3

[0058] A super duplex stainless steel self-protected flux-cored welding wire adopts SUS430 steel strip as the outer skin, the size of the steel strip is 0.9×14mm, the filling rate of the flux-cored powder in the steel strip is 20.0%, and the diameter of the welding wire is 1.2mm. According to the total mass percentage of 100%, the chemical composition of the steel strip is: Cr17.0%, Mo 3.0%, Mn 0.40%, Si 0.30%, Ni 0.20%, and the rest are iron; the core powder is alloy powder, Chemical composition: Cr 8.0%, Ni 4.0%, V 1.0%, N 0.2%, Fe 3 O 4 -Al 2 O 3 -Li 2 CO 3 6.0%, La 2 O 3 0.8%, MnS 0.4%, Al-Mg 2.0%, Ti 1.0%, and the rest is iron.

[0059] The average particle size of the core powder is 100-150 μm, and the nano-nucleating agent La 2 O 3 , The particle size of MnS is 50-80nm, and the purity is 99.9%.

[0060] The preparation method of the super duplex stainless steel self-protected flux-cored welding wire of the present embodiment includes the following specific ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com