Wholly aromatic polyester and polyester resin composition

A technology of wholly aromatic polyester and polyester resin, applied in the field of polyester resin composition and wholly aromatic polyester, can solve the problems of inability to maintain mechanical strength and high melt processing, and achieve less production of sublimed products, Foreign body reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Examples are shown below to describe the present invention more specifically, but the present invention is not limited to these Examples.

[0102]

[0103] Into a polymerization vessel equipped with a stirrer, a reflux column, a monomer input port, a nitrogen gas inlet, and a decompression / outflow line, the following raw material monomers, fatty acid metal salt catalyst, and acylating agent were charged, and nitrogen replacement was started.

[0104] (I) 0.883 mol (48 mol%) of 6-hydroxy-2-naphthoic acid (HNA)

[0105] (II) 0.037 mol (2 mol%) of 4-hydroxybenzoic acid (HBA)

[0106] (III) 0.46 mol (25 mol%) of 1,4-phthalic acid (TA)

[0107] (IV) 0.46 mol (25 mol%) of 4,4'-dihydroxybiphenyl (BP)

[0108] Potassium acetate catalyst 150ppm

[0109] Tris(2,4-pentanedione)cobalt(III) catalyst 150ppm

[0110] 1.91 moles of acetic anhydride (1.04 times the total hydroxyl equivalent of HNA, HBA, and BP)

[0111] After feeding the raw materials, the temperature of the reac...

Embodiment 2~4

[0124]

[0125] A polymer was obtained in the same manner as in Example 1, except that the type, amount (mol%), and temperature increase rate of the raw material monomers were as shown in Table 1 and Table 2. In addition, the same evaluation as in Example 1 was performed (the melt viscosity of Example 4 and Comparative Example 4 was measured at a temperature of 350° C.). The evaluation results are shown in Table 1 and Table 2.

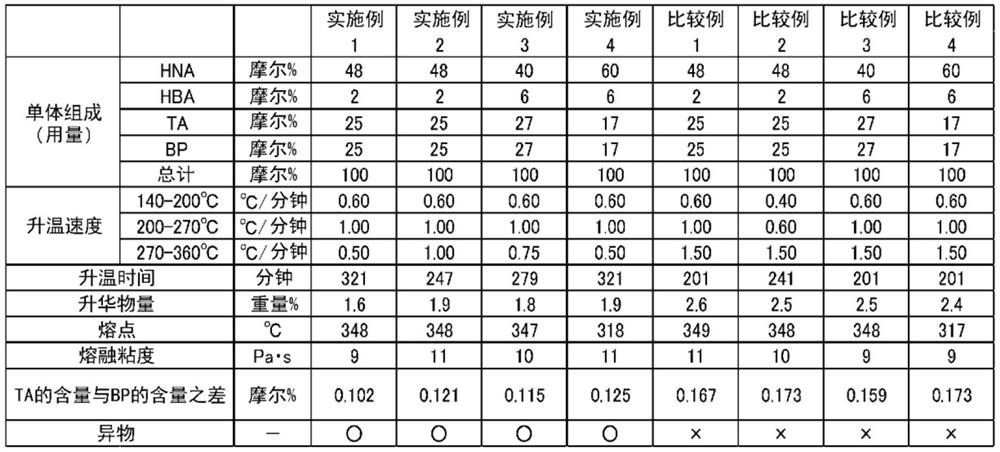

[0126] [Table 1]

[0127]

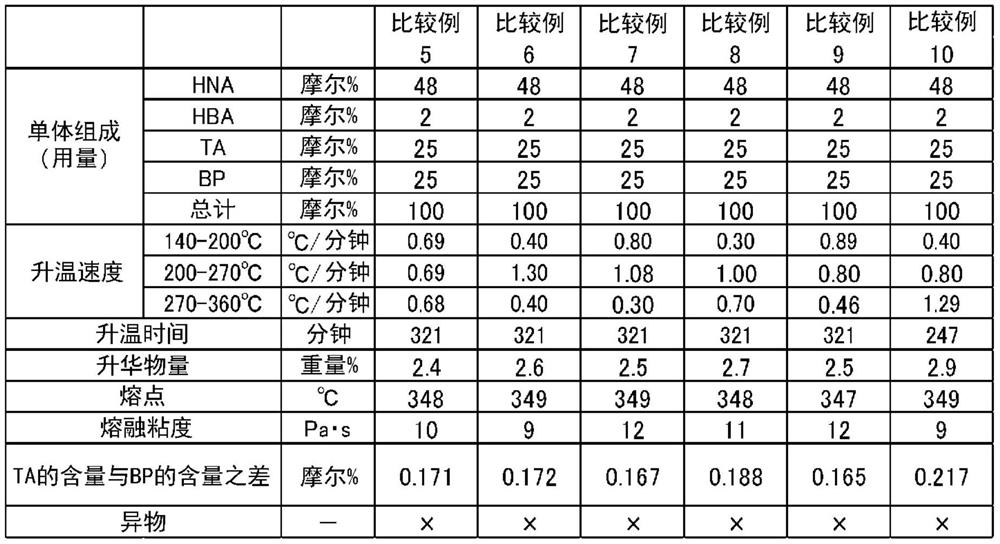

[0128] [Table 2]

[0129]

[0130] In addition, as shown in Table 2, in Comparative Example 8 in which the rate of temperature increase from 140° C. to 200° C. was 0.30° C. / minute, and in Comparative Example 9 in which the rate of temperature increase was 0.89° C. / minute, foreign matter was generated. In addition, as shown in Tables 1 and 2, in Comparative Example 2 in which the temperature increase rate from 200°C to 270°C was 0.60°C / min, in Comparative Example 5 at 0.69°C / min, and in Comparative Example 6 at 1.30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com