Curable resin composition, overcoats, and process for formation thereof

A technology of curable resin and composition, which can be used in electric solid devices, semiconductor/solid device parts, instruments, etc., and can solve problems such as poor display, contamination of panel substrates, difficult baking conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach -

[0254] When the preferable embodiment of each curable resin composition of this invention is shown more concretely, there are following (I)-(IV).

[0255] (1) One-component curable resin composition (α) containing polymer (A) (preferably at least one of copolymer (A1), copolymer (A2) and copolymer (A3) A) and (B) the cationic polymerizable compound, depending on the situation, also contain the following optional additive components, relative to 100 parts by weight of the polymer (A), the amount of the cationic polymerizable compound is 3-100 parts by weight, more preferably 5-50 parts by weight.

[0256] In this one-component curable resin composition (α), a protective film having sufficient surface hardness can be obtained by making the usage-amount of the cationically polymerizable compound within the above-mentioned range. The one-component curable resin composition (α) is particularly excellent in long-term storage stability.

[0257] (II) A one-component curable resin c...

Embodiment

[0306] Synthesis examples and examples are given below to further describe the present invention in detail, but the present invention is not limited to the following examples.

[0307]

[0308] Device: GPC-101 (manufactured by Showa Denko Co., Ltd.)

[0309] Column: Combine GPC-KF-801, GPC-KF-802, GPC-KF-803 and GPC-KF-804

[0310] Mobile phase: tetrahydrofuran containing 0.5 wt% phosphoric acid.

[0311] Synthesis of Copolymer (A)

Synthetic example 1

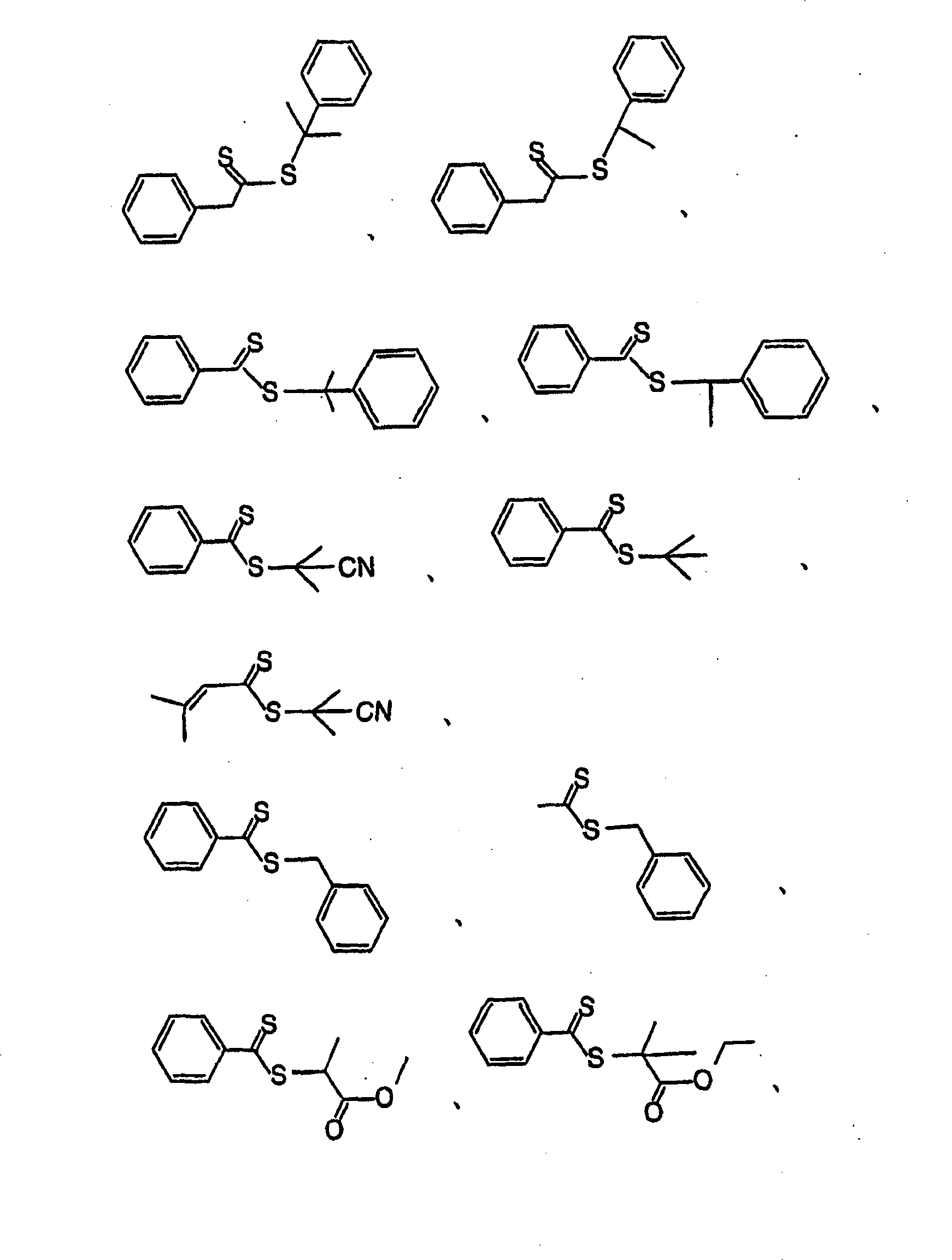

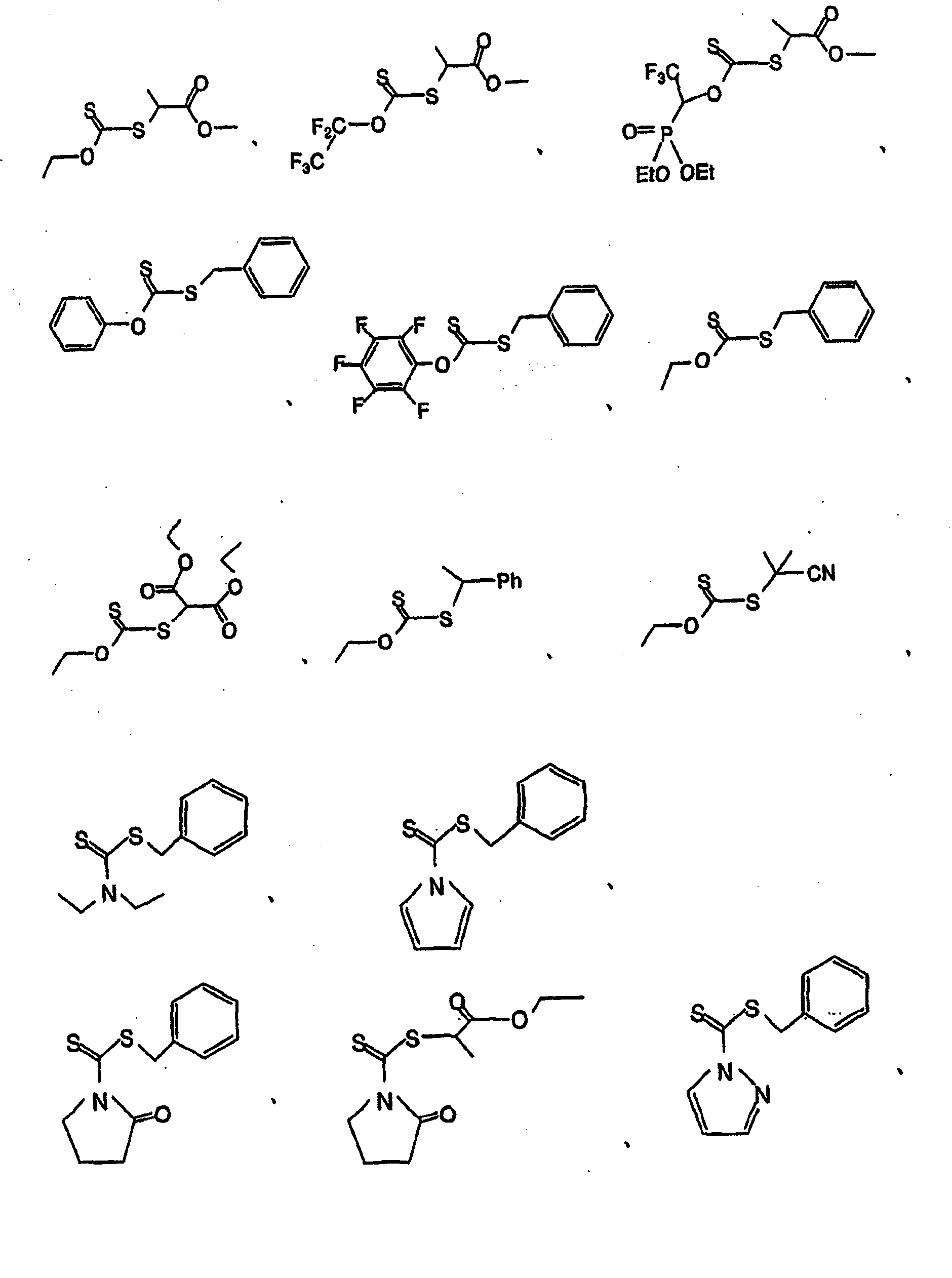

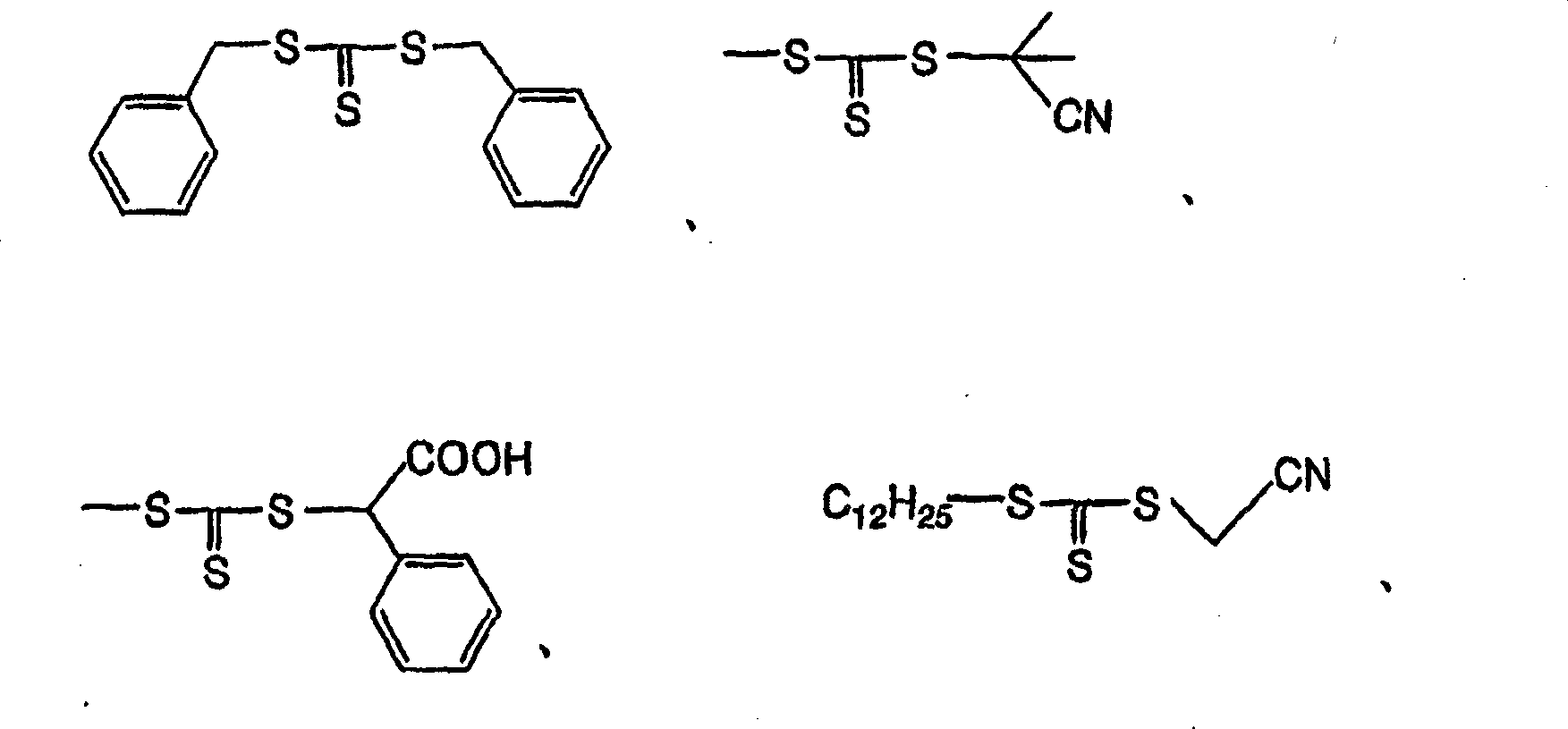

[0313] Add 1 part by weight of azobisisobutyronitrile, 4 parts by weight of cumyl dithiobenzoate and 50 parts by weight of diethylene glycol ethyl methyl ether in the flask equipped with condenser tube and stirrer. Then add 80 parts by weight Parts of glycidyl methacrylate and 20 parts by weight of styrene, after replacing with nitrogen, stir slowly. Raise the temperature of the reaction solution to 60°C, keep the temperature for 24 hours, and then add 3 parts by weight of azobisisobutyronitrile , then stirred at 60°C for 4 hours, and added 200 parts by weight of diethylene glycol ethyl methyl ether to obtain a solution of the copolymer (A-1). The polystyrene-equivalent weight-average molecular weight (Mw) of the copolymer (A-1) ) was 10,000, the molecular weight distribution (Mw / Mn) was 1.3, and the residual monomer was 1.7% by weight. The solid concentration of the polymer solution was 29.7% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com