Anti-static aluminum oxide ceramic material and preparation method thereof

An alumina ceramic and anti-static technology, applied in the field of functional ceramics, can solve problems such as poor dispersion, difficult preparation, and reduced strength, and achieve the effects of ensuring density and strength, simple preparation process, and improving processing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

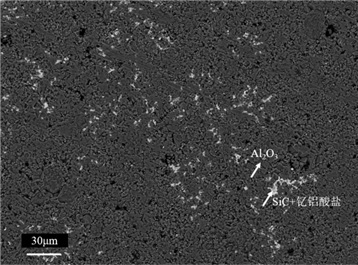

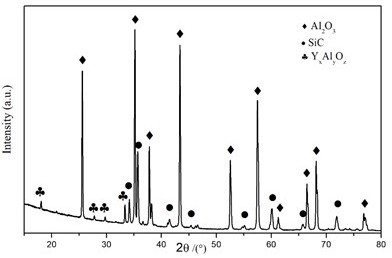

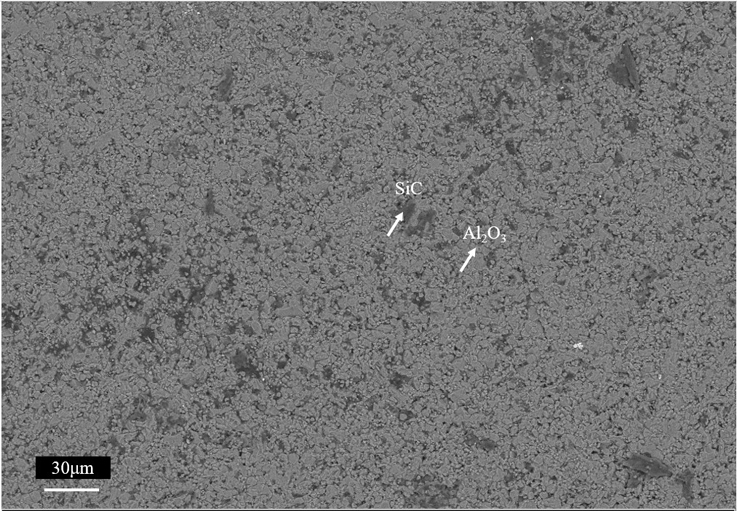

Image

Examples

Embodiment 1

[0041](1) Add 4g of N-methylolacrylamide, 0.1g of N,N'-methylenebisacrylamide, 0.2g of defoamer and 1g of polyacrylamide into 25g of pure water, and stir for 15 minutes until all materials Dissolve in pure water; add 1g of yttrium oxide powder and 4g of α-silicon carbide powder with a particle size of 200nm to the resulting solution, stir for 15 minutes until the powder is dispersed in the solution; then add 95g of alumina powder into the solution Continue stirring for 20 minutes until the powder is evenly dispersed to obtain a slurry with a solid content of 80% and good fluidity; then add 0.1 g of ammonium persulfate to the slurry and stir for 10 minutes; obtain a mixed slurry;

[0042] (2) Put the obtained mixed slurry in a vacuum machine to evacuate and stir to remove air bubbles, and the vacuum degree is -0.09Mpa; slowly pour the mixed slurry with removed air bubbles into the glass mold prepared in advance along the wall, and then place the glass mold on the Curing is carr...

Embodiment 2

[0045] (1) Add 5g of N-methylolacrylamide, 0.05g of N,N'-methylenebisacrylamide, 0.1g of defoamer and 0.1g of polyacrylamide into 25g of pure water, and stir for 10 minutes until all materials All were dissolved in pure water; 3g of yttrium oxide powder and 5g of α-silicon carbide powder with a particle size of 500nm were added to the resulting solution, and stirred for 10 minutes until the powders were all dispersed in the solution; Aluminum powder, continue to stir for 25 minutes until the powder is evenly dispersed to obtain a slurry with a solid content of 80% and good fluidity; then add 0.05g of ammonium persulfate to the slurry, and stir for 10 minutes to obtain a mixed slurry;

[0046] (2) Put the mixed slurry in the vacuum machine to evacuate and stir to remove air bubbles, the vacuum degree is -0.09Mpa; then slowly pour the mixed slurry after removing the air bubbles into the glass mold prepared in advance along the wall, and then put the glass mold As for curing in a...

Embodiment 3

[0049] (1) Add 5g of N-methylolacrylamide, 0.05g of N,N'-methylenebisacrylamide, 0.1g of defoamer and 0.1g of polyacrylamide into 25g of pure water, and stir for 12 minutes until all materials All were dissolved in pure water; 5g of yttrium oxide powder and 5g of α-silicon carbide powder with a particle size of 1μm were added to the resulting solution, and stirred for 12 minutes until the powders were all dispersed in the solution; then 90g of yttrium oxide was added to the resulting solution Aluminum powder, continue to stir for 25 minutes until the powder is evenly dispersed to obtain a slurry with a solid content of 80% and good fluidity; then add 0.05 g of ammonium persulfate to the slurry, and stir for 12 minutes to obtain a mixed slurry;

[0050] (2) Put the mixed slurry in a vacuum machine to evacuate and stir to remove air bubbles, the vacuum degree is -0.09Mpa; then slowly pour the obtained slurry after removing air bubbles into the glass mold prepared in advance along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com