Concrete waste slurry slag grinding aid and preparation method thereof

A grinding aid and concrete technology, applied in the field of concrete waste slurry disposal, can solve the problems such as grinding efficiency and effect not meeting application requirements, energy waste, etc., to improve activity and filling effect, reduce particle agglomeration, and improve material fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

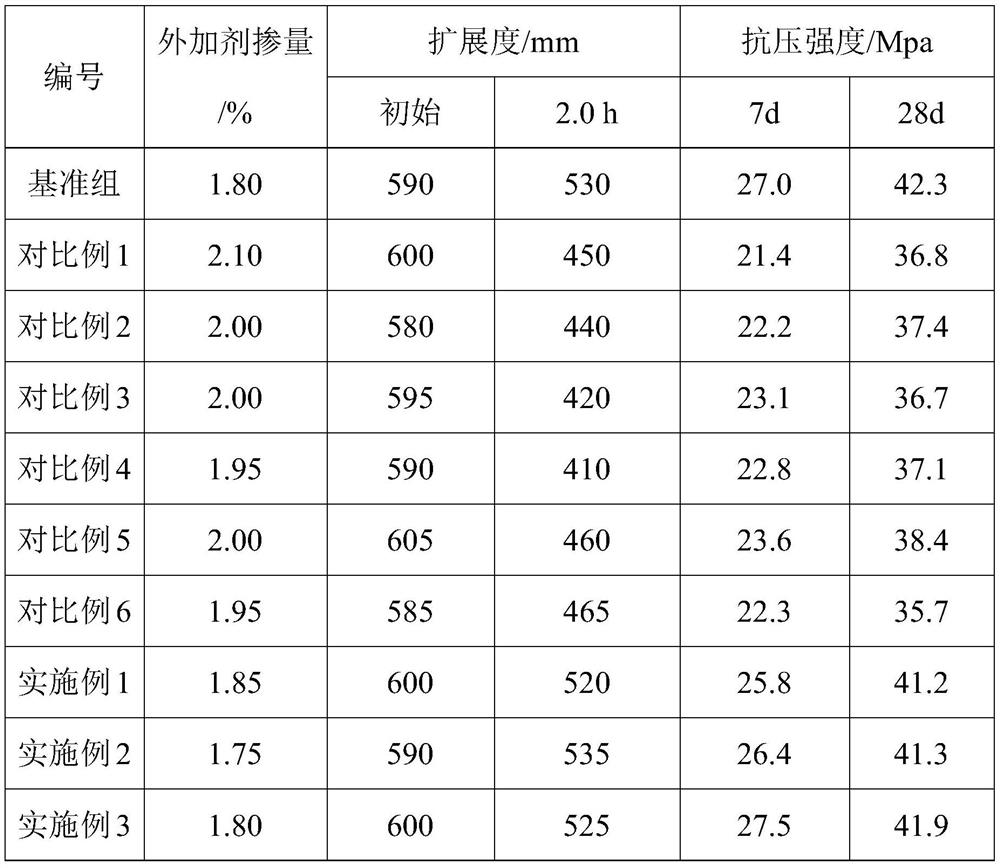

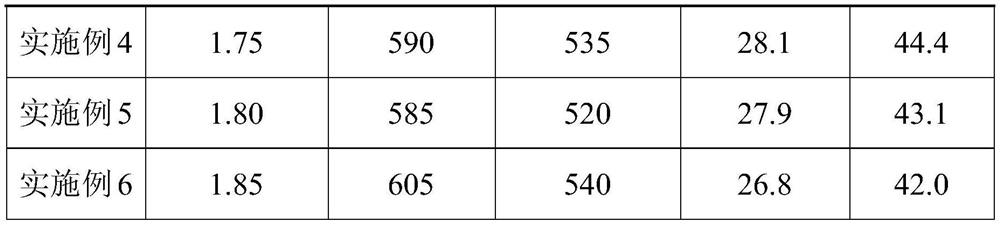

Examples

Embodiment 1

[0042] A preparation method of concrete waste slurry slag grinding aid, the specific steps are as follows:

[0043] (1) Weigh 55g of polyether polyol, 80g of diethanolamine, 10g of water and 1g of potassium bicarbonate in a reaction vessel with a condensing device, stir and mix evenly to obtain a clear liquid;

[0044] (2) Weigh 24g of butyl orthosilicate and quickly add it to the liquid in step 1), at room temperature, the rotation speed is 4000rpm, and continue to stir rapidly for 0.5h to obtain a uniform suspension;

[0045] (3) Immerse the reaction vessel containing the suspension obtained in step (2) in an oil bath at 70° C., adjust the rotation speed to 800 rpm, and stir for 24 hours to obtain a silica dispersion modified with hydroxyl and alcohol amino groups;

[0046] (4) Weigh 30g of phosphorus oxychloride, add it continuously to the silica dispersion in step (3) within 0.5h, control the reaction temperature at 90°C, and react for 3h to prepare the concrete waste slur...

Embodiment 2

[0048] A preparation method of concrete waste slurry slag grinding aid, the specific steps are as follows:

[0049](1) Weigh 70g of ethylene glycol, 100g of triethanolamine, 6g of water and 0.2g of potassium carbonate in a reaction vessel with a condensing device, stir and mix evenly to obtain a clear liquid;

[0050] (2) Weigh 13.8g of methyl orthosilicate and quickly add it to the liquid in step 1), at room temperature, the rotation speed is 1500rpm, and continue to stir rapidly for 1h to obtain a uniform suspension;

[0051] (3) Immerse the reaction vessel containing the suspension obtained in step (2) in an oil bath at 90° C., adjust the rotation speed to 400 rpm, and stir for 24 hours to obtain a silica dispersion modified with hydroxyl and alcohol amino groups;

[0052] (4) Weigh 10 g of phosphorus pentoxide, continuously add it to the silica dispersion in step 3) within 1 h, control the reaction temperature at 60° C., and react for 6 h to prepare the concrete waste slur...

Embodiment 3

[0054] A preparation method of concrete waste slurry slag grinding aid, the specific steps are as follows:

[0055] (1) Weigh 57.4g propylene glycol, 76.6g triethanolamine, 9g water and 0.6g histidine in a reaction vessel with a condensing device, stir and mix evenly to obtain a clear liquid;

[0056] (2) Weigh 21.1 g of propyl orthosilicate and quickly add it to the liquid in step 1), at room temperature, with a rotation speed of 2500 rpm, and continue to stir rapidly for 1 hour to obtain a uniform suspension;

[0057] (3) Immerse the reaction vessel containing the suspension obtained in step (2) in an oil bath at 80° C., adjust the rotation speed to 600 rpm, and stir for 24 hours to obtain a silica dispersion modified with hydroxyl and alcohol amino groups;

[0058] (4) Weigh 26.8g of pyrophosphoric acid, continuously add it to the silica dispersion in step 3) within 0.5h, control the reaction temperature at 80°C, and react for 5h to prepare the concrete waste slurry slag gr...

PUM

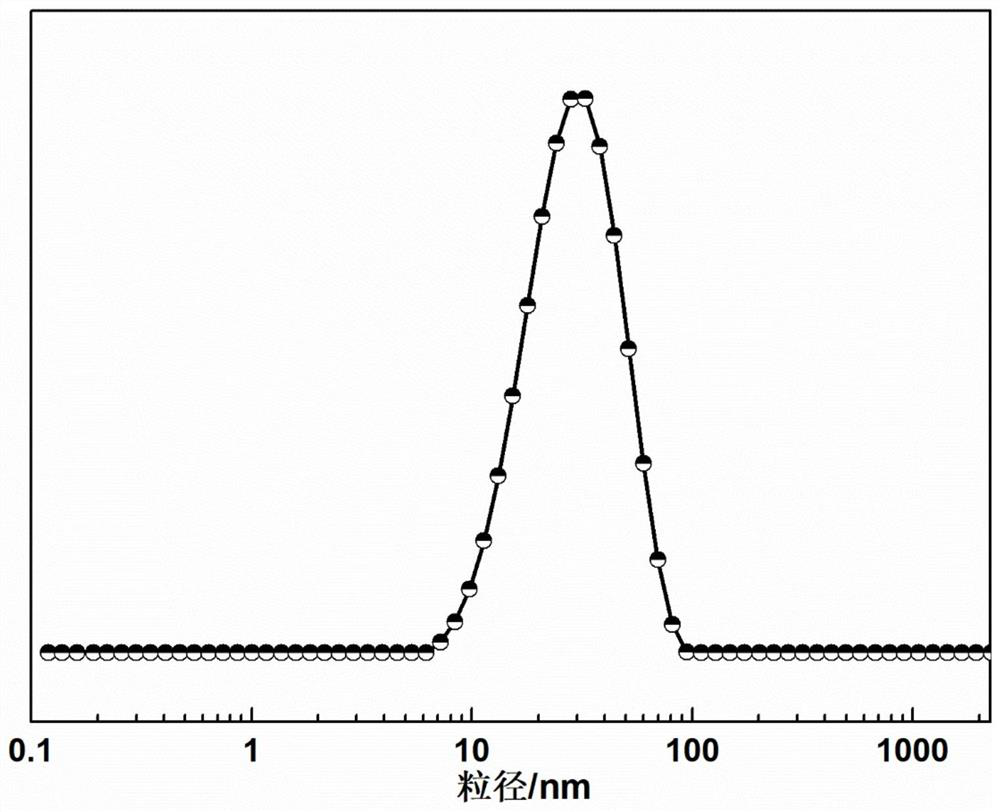

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com