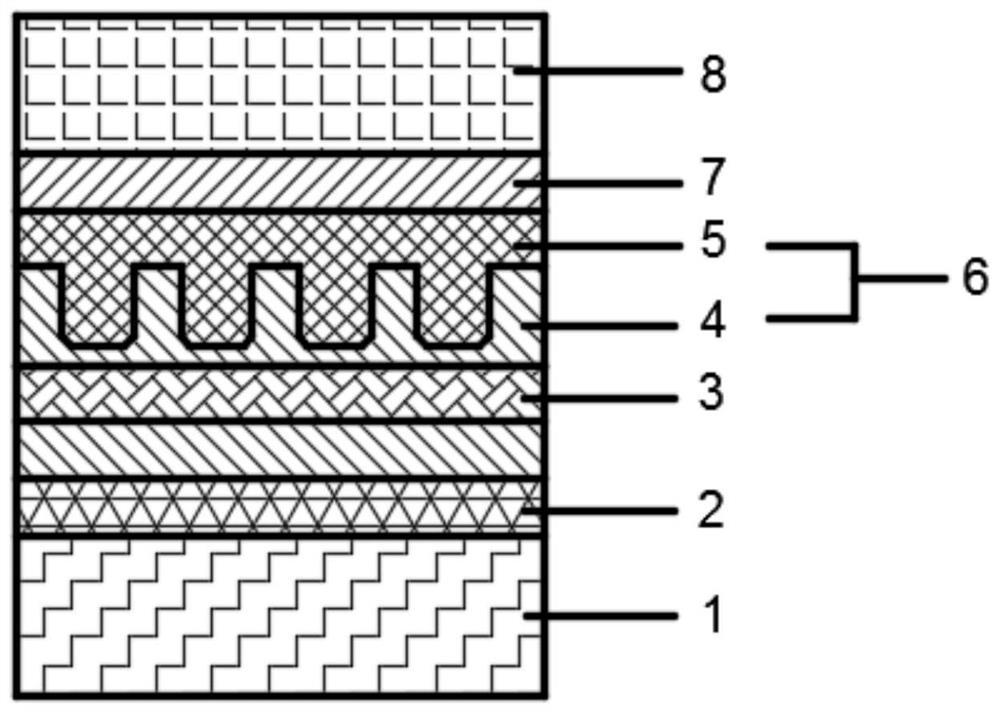

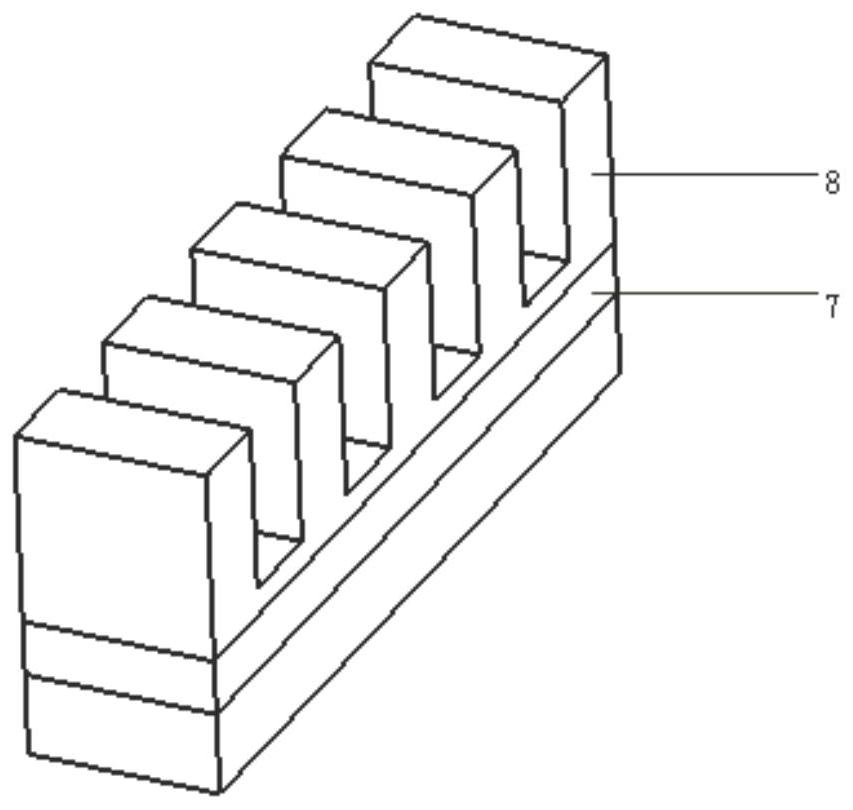

Asphalt pavement structure

An asphalt pavement and bitumen technology, applied in the field of highway and urban road engineering, can solve the problems that the service life is difficult to meet the design requirements, road surface damage, etc., and achieve the effects of reducing the occurrence of early diseases, prolonging the service life and improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of nanocellulose thermoplastic polymer composite modifier:

[0072] Step 1: Add 4 parts of SBS polymer to 12 parts of low-boiling point organic solvent (this organic solvent is a mixture of hexane and ethyl acetate, and its mixing ratio is mass ratio cyclohexane:ethyl acetate=2:8~ 5:5), after fully dissolving, slowly add 12 parts of deionized water to the polymer organic solution, and then add 0.2 parts of emulsifier. Shearing on a high-speed emulsifying shear until fully emulsified, and then removing the organic solution by vacuum distillation to obtain a polymer emulsion;

[0073] Step 2: Add 0.5 parts of TEMPO oxidized wood pulp nanocellulose to 50 parts of deionized water, and obtain a uniformly dispersed nanocellulose aqueous solution through ultrasonic oscillation and magnetic stirring;

[0074] Step 3: Slowly add the nanocellulose aqueous solution prepared in step 2 to the polymer emulsion prepared in step 1, and use a high-speed emulsification s...

Embodiment 2

[0084] (1) Preparation of nanocellulose thermoplastic polymer composite modifier:

[0085] Step 1: Add 6 parts of SBS polymer to 18 parts of low-boiling point organic solvent (this organic solvent is a mixture of hexane and ethyl acetate, and its mixing ratio is mass ratio cyclohexane:ethyl acetate=2:8~ 5:5), after fully dissolving, slowly add 18 parts of deionized water to the polymer organic solution, and then add 0.4 parts of emulsifier. Shearing on a high-speed emulsifying shear until fully emulsified, and then removing the organic solution by vacuum distillation to obtain a thermoplastic polymer emulsion;

[0086] Step 2: Add 3 parts of TEMPO oxidized wood pulp nanocellulose to 300 parts of deionized water, and obtain a uniformly dispersed nanocellulose aqueous solution through ultrasonic oscillation and magnetic stirring;

[0087] Step 3: Slowly add the nanocellulose aqueous solution prepared in step 2 to the thermoplastic polymer emulsion prepared in step 1, and use a ...

Embodiment 3

[0097] (1) Preparation of nanocellulose thermoplastic polymer composite modifier:

[0098] Step 1: 5 parts of SBS polymers are added to 15 parts of low-boiling point organic solvents (the organic solvent is a mixture of hexane and ethyl acetate, and the mixing ratio is mass ratio cyclohexane:ethyl acetate=2:8~ 5:5), after fully dissolving, slowly add 15 parts of deionized water to the polymer organic solution, and then add 0.3 parts of emulsifier. Shearing on a high-speed emulsifying shear until fully emulsified, and then removing the organic solution by vacuum distillation to obtain a thermoplastic polymer emulsion;

[0099] Step 2: Add 2 parts of TEMPO oxidized wood pulp nanocellulose to 200 parts of deionized water, and obtain a uniformly dispersed nanocellulose aqueous solution through ultrasonic oscillation and magnetic stirring;

[0100] Step 3: Slowly add the nanocellulose aqueous solution prepared in step 2 to the thermoplastic polymer emulsion prepared in step 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com