High-temperature-resistant flame-retardant sealing ring and preparation method thereof

A sealing ring, high temperature resistance technology, applied in the field of high temperature flame retardant sealing ring and its preparation, can solve the problems of deformation of rubber sealing ring, influence of sintering furnace operation, high cost of construction, good heat insulation, excellent resistance to external environment flammability, and the effect of suppressing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

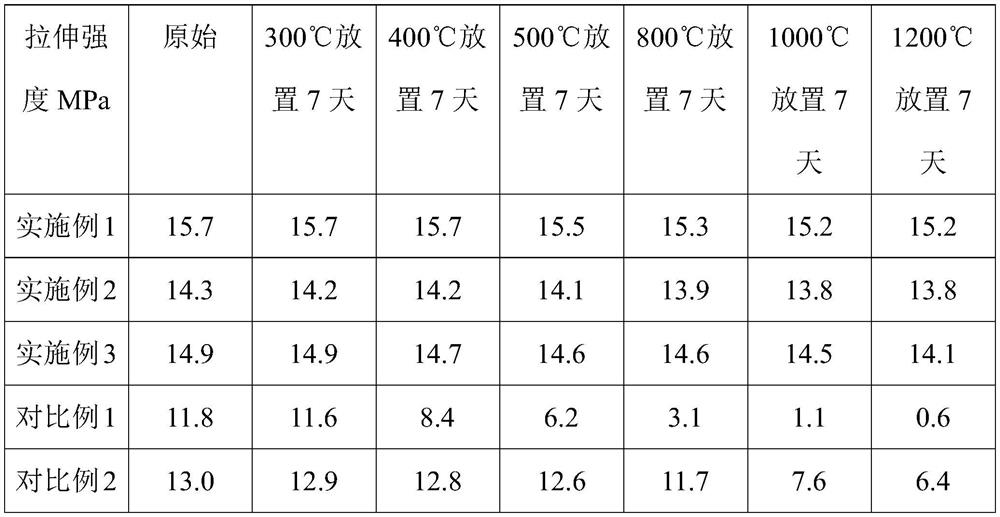

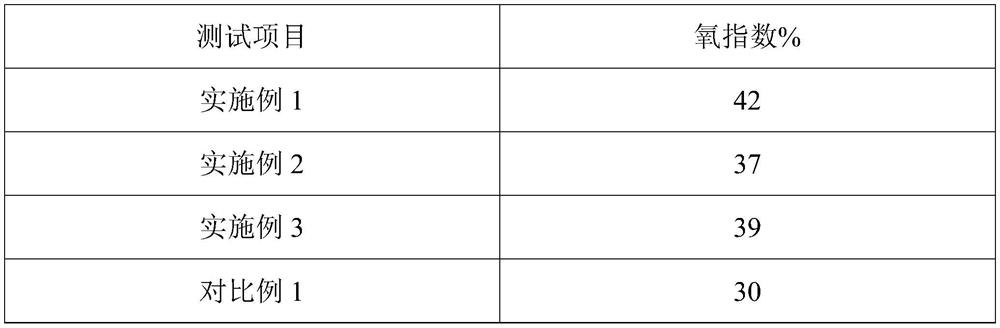

Embodiment 1

[0036] A heat-resistant and flame-retardant sealing ring, comprising the following raw materials in parts by weight: 70 parts of phenolic resin, 75 parts of polyvinyl chloride, 30 parts of polyacrylate rubber, 2 parts of zinc dimethyl dithiocarbamate, di-salt 5 parts of lead phosphite, 18 parts of antimony trioxide, 7 parts of aluminum hydroxide, 8 parts of silicon dioxide, 16 parts of titanium dioxide, 20 parts of dioctyl phthalate, 75 parts of vermiculite powder, chloroprene rubber 28 parts and 85 parts of toluene. Wherein, the phenolic resin is synthesized from phenol and formaldehyde as raw materials. The polyacrylate rubber is methyl acrylate rubber. Vermiculite powder was ground to a particle size of 5 mm.

[0037] A method for preparing a high-temperature-resistant and flame-retardant sealing ring comprises the following steps:

[0038] 1) Mix toluene and chloroprene rubber to make a solution, then add vermiculite to obtain a mixture; keep the mixture in a sealed sta...

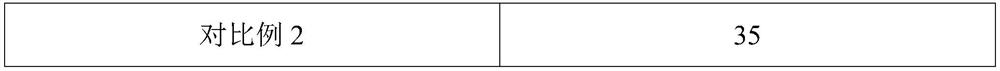

Embodiment 2

[0043]A high-temperature-resistant and flame-retardant sealing ring, comprising the following raw materials in parts by weight: 60 parts of phenolic resin, 50 parts of polyvinyl chloride, 20 parts of polyacrylate rubber, 1 part of zinc dimethyl dithiocarbamate, di-salt 3 parts of lead phosphite, 10 parts of antimony trioxide, 5 parts of aluminum hydroxide, 5 parts of silicon dioxide, 5 parts of titanium dioxide, 15 parts of dioctyl phthalate, 50 parts of vermiculite powder, chloroprene rubber 20 parts and 80 parts of toluene.

[0044] Wherein, the phenolic resin is synthesized from cresol and acetaldehyde as raw materials. Polyacrylate rubber is ethyl acrylate rubber. Vermiculite powder was ground to 3mm.

[0045] A method for preparing a high-temperature-resistant and flame-retardant sealing ring comprises the following steps:

[0046] 1) Mix toluene and chloroprene rubber to make a solution, then add vermiculite to obtain a mixture; keep the mixture in a sealed state to a...

Embodiment 3

[0051] A heat-resistant and flame-retardant sealing ring, comprising the following raw materials in parts by weight: 80 parts of phenolic resin, 100 parts of polyvinyl chloride, 40 parts of polyacrylate rubber, 3 parts of zinc dimethyl dithiocarbamate, di-salt 6 parts of lead phosphite, 30 parts of antimony trioxide, 10 parts of aluminum hydroxide, 15 parts of silicon dioxide, 30 parts of titanium dioxide, 30 parts of dioctyl phthalate, 80 parts of vermiculite powder, chloroprene rubber 30 parts and 90 parts of toluene. Wherein, the phenolic resin is synthesized from bisphenol A and formaldehyde as raw materials. Polyacrylate rubber is butyl acrylate rubber. Vermiculite powder was ground to 5mm.

[0052] A method for preparing a high-temperature-resistant and flame-retardant sealing ring comprises the following steps:

[0053] 1) Mix toluene and chloroprene rubber to make a solution, then add vermiculite to obtain a mixture; keep the mixture in a sealed state to avoid absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com