A green slow-burning pyrotechnic agent binder and preparation method thereof

A technology of pyrotechnics and binders, which is applied in the direction of explosives processing equipment, non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, etc. and other problems, to achieve the effects of reducing reaction energy consumption and difficulty of separation and purification, good compatibility, and improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

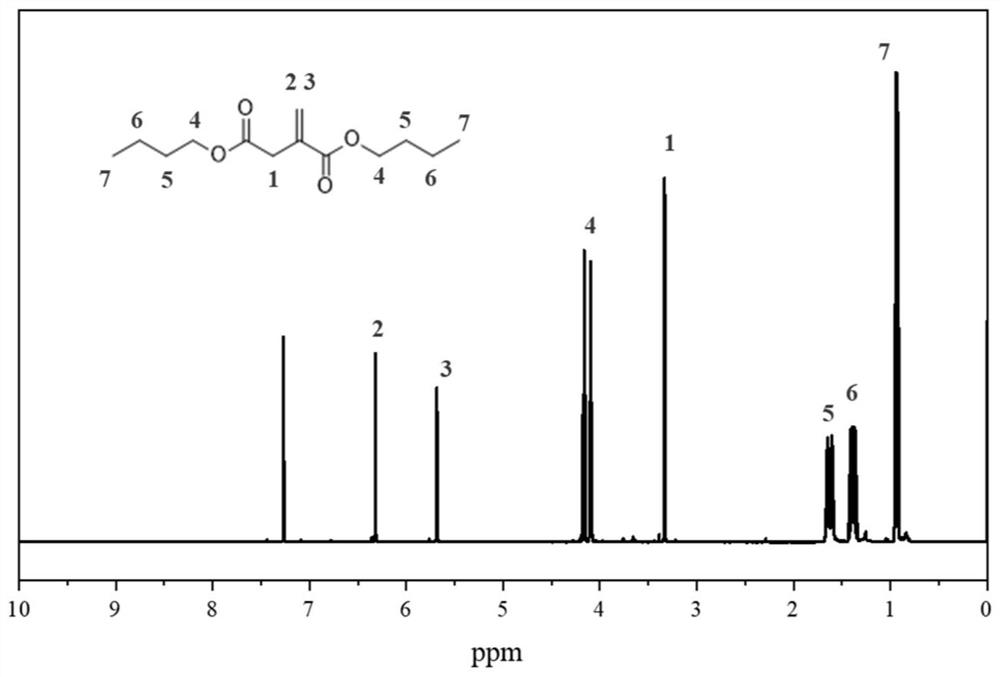

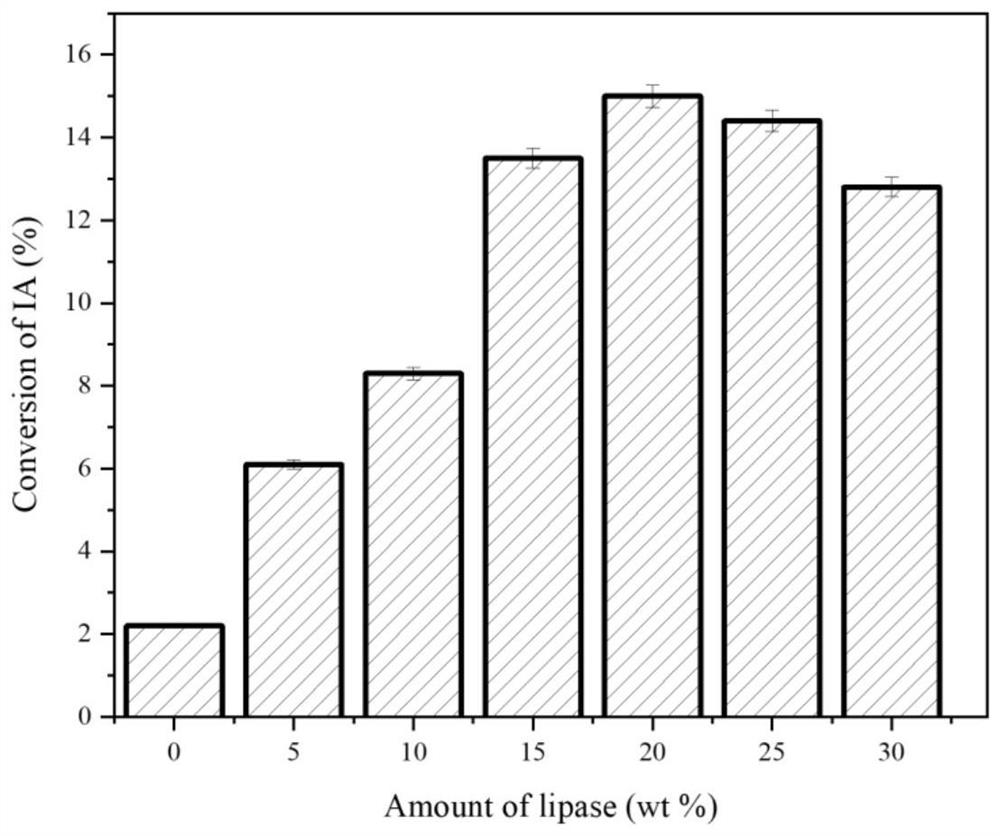

[0043] Mix n-butanol and itaconic acid at a molar ratio of 13:1 to obtain a mixed solution, then add lipase Novozym435 to the mixed solution, the amount of lipase Novozym435 added is 20% of the mass of itaconic acid, and stir at 80°C Carry out atmospheric pressure esterification reaction 12h, obtain the mixture of dibutyl itaconate and monobutyl itaconate, filter and remove lipase Novozym435 after dissolving the mixture in tetrahydrofuran, then add dibutyl itaconate and monobutyl itaconate Water was added to the mixture of butyl esters and allowed to stand for stratification, and the water and monobutyl itaconate in the upper layer were removed to obtain pure dibutyl itaconate. Add initiator benzoyl peroxide (BPO) in the pure product of dibutyl itaconate, the addition of BPO is 1% of the pure product quality of dibutyl itaconate, carry out homopolymerization reaction 40min under 65 ℃ of conditions , to obtain poly(dibutyl itaconate) (PDIB), the pyrotechnics binder.

[0044] T...

Embodiment 2

[0048] Same as Example 1, the only difference is that the homopolymerization time is 80min.

[0049] The same detection as in Example 1 was carried out.

[0050] Results: The number-average molecular weight Mn=10178g / mol, the weight-average molecular weight Mw=19052g / mol, and the dispersion index PDI=1.57 of the poly(dibutyl itaconate) prepared in this example; the conversion rate of dibasic acid reached 98.5%.

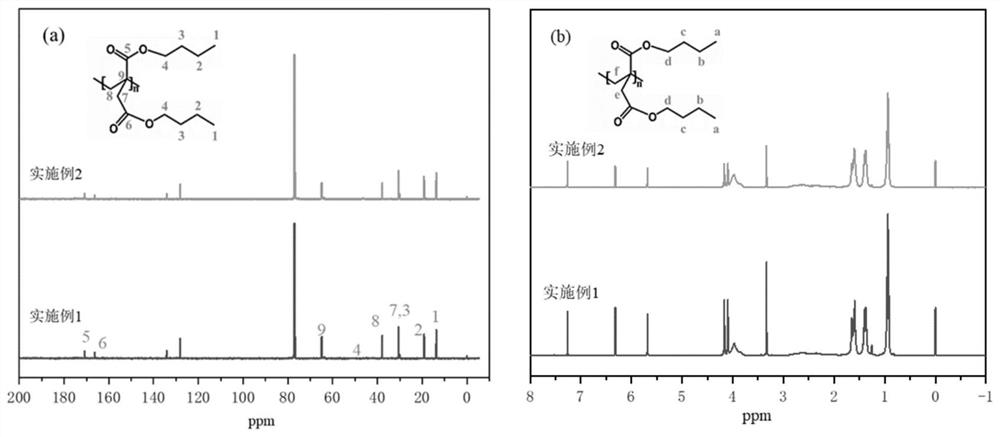

[0051] Carry out to the polybutylene itaconate that embodiment 1,2 make 13 C NMR spectrum and 1 HNMR detection, the results are as follows figure 2 Shown; Wherein, (a) is carbon spectrogram, (b) is hydrogen spectrogram. Depend on figure 2 (a) It can be seen that the peaks at 134.10ppm and 127.70ppm gradually disappear with time, representing two olefinic carbons that gradually disappear after polymerization; two (C=O) groups (167.70ppm and 171.80ppm) and ( -OCH 2 The signal of -) units (64.60 ppm) indicated the presence of dibutyl itaconate units in the polyme...

Embodiment 3

[0055] Same as Example 1, the only difference is that itaconic acid is replaced by fumaric acid, and the mol ratio of fumaric acid and n-butanol is 15:1; lipase is porcine pancreatin; Adding water to the mixture with monobutyl fumarate is replaced by adding NaOH to remove monobutyl fumarate; the amount of initiator added is 1%; the temperature of homopolymerization is 50° C. and the time is 100 min.

[0056] The same detection as in Example 1 was carried out.

[0057] Results: The polydibutyl fumarate prepared in this example has a number average molecular weight Mn=5389g / mol, a weight average molecular weight Mw=7899g / mol, and a dispersibility index PDI=1.35. The conversion rate of dibasic acid reaches 98.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com