Method for recovering platinum from waste

A waste recycling and platinum technology, applied in the direction of improving process efficiency, can solve the problems of affecting recycling efficiency, difficult to improve platinum recycling rate, etc., and achieve the effect of improving extraction rate, improving activation efficiency, and improving purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

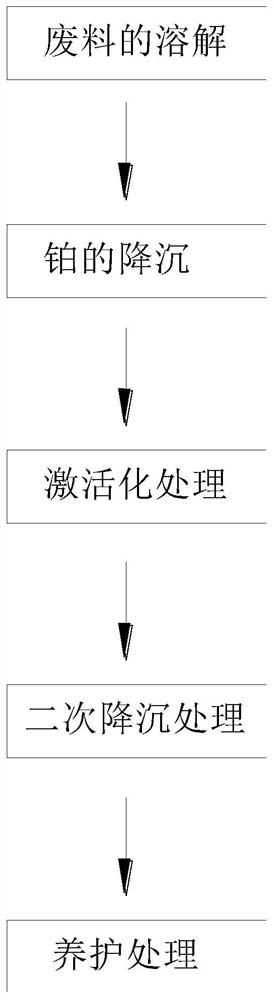

[0035] A kind of method of reclaiming platinum from waste material of the present embodiment, comprises the following steps:

[0036] Step 1: Dissolution of waste materials:

[0037] Mix precious metal waste and aqua regia at a weight ratio of 8:1, and then carry out stirring and dissolving treatment in the reactor. The temperature of stirring and dissolving is 80°C, the dissolution time is 30min, and the stirring speed is 100r / min. After the stirring is completed, the waste Dissolve completely;

[0038] Step 2: Settling of platinum:

[0039] Add ammonium chloride solution with a mass fraction of 30% to the dissolving material in step 1, then stir at a speed of 100r / min for 10 minutes, then let it stand for precipitation to obtain ammonium chloroplatinate, and finally use solution washing to obtain a sinking platinum material ;

[0040] Step 3: Activation processing:

[0041] S1: Send the sedimentation platinum material and modified clay into deionized water for ultrasonic...

Embodiment 2

[0057] A kind of method of reclaiming platinum from waste material of the present embodiment, comprises the following steps:

[0058] Step 1: Dissolution of waste materials:

[0059]The precious metal waste and aqua regia were mixed according to the weight ratio of 8:1, and then stirred and dissolved in the reactor. The temperature of stirring and dissolving was 120 ° C, the dissolution time was 40 min, and the stirring speed was 600 r / min. After stirring, the waste was dissolved. dissolve completely;

[0060] Step 2: Settlement of platinum:

[0061] Add 40% mass fraction of ammonium chloride solution to the dissolving material in step 1, then stir at a speed of 300r / min for 20min, then stand for precipitation to obtain ammonium chloroplatinate, and finally use the solution to wash to obtain sedimentation platinum material ;

[0062] Step 3: Activation processing:

[0063] S1: put the precipitated platinum material and the modified clay into deionized water for ultrasonic ...

Embodiment 3

[0079] A method for recycling platinum from waste material of the present embodiment, comprising the following steps:

[0080] Step 1: Dissolution of waste:

[0081] The precious metal waste and aqua regia were mixed according to the weight ratio of 8:1, and then stirred and dissolved in the reaction kettle. The temperature of stirring and dissolving was 100 ° C, the dissolution time was 35 min, and the stirring speed was 300 r / min. After stirring, the waste was dissolved. dissolve completely;

[0082] Step 2: Settlement of platinum:

[0083] Add ammonium chloride solution with a mass fraction of 35% to the dissolving material in step 1, then stir at a speed of 200 r / min for 15 minutes, then stand for precipitation to obtain ammonium chloroplatinate, and finally use the solution to wash to obtain sedimentation platinum material ;

[0084] Step 3: Activation processing:

[0085] S1: put the precipitated platinum material and the modified clay into deionized water for ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com