Hydrogel film and preparation method thereof and ultrasonic coupling patch

A technology of hydrogel film and mixed solution, which is applied in echo/ultrasound imaging agents, drug delivery, emulsion delivery, etc. It can solve the problems of affecting imaging quality and difficult to see superficial tissues, etc., and achieve high imaging quality and easy scale The effect of optimizing production and application and avoiding risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

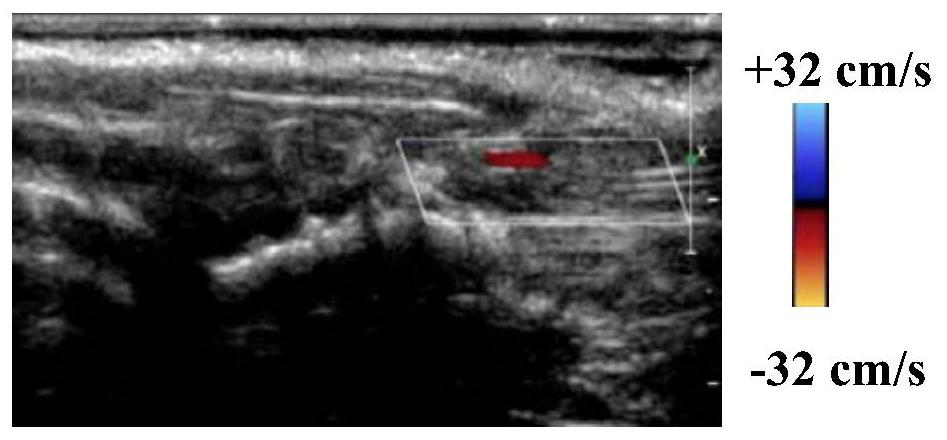

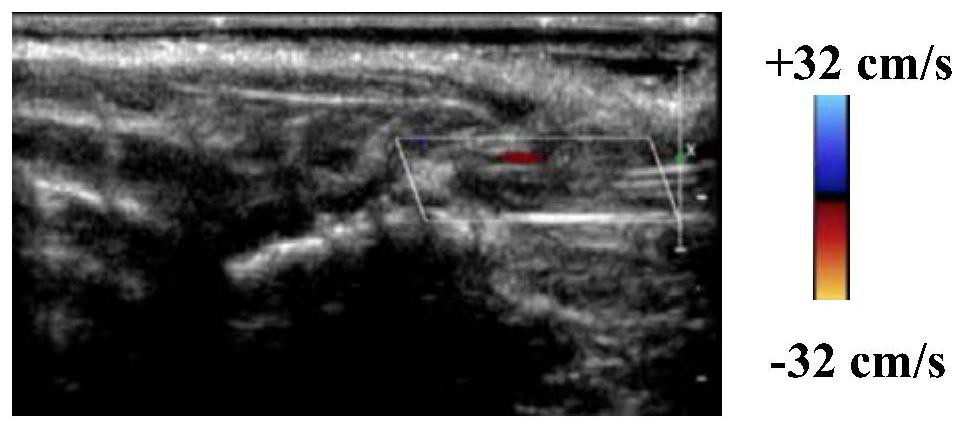

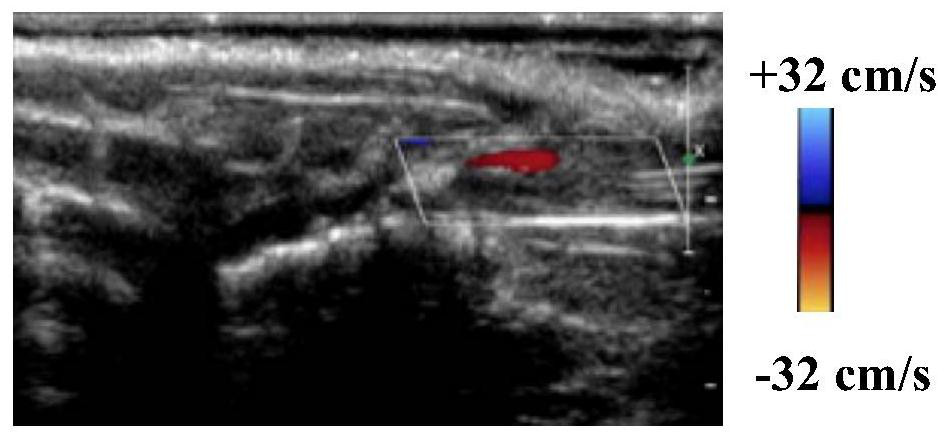

Image

Examples

preparation example Construction

[0070] The present invention also provides the preparation method of above-mentioned hydrogel film, and technical scheme is:

[0071] A method for preparing a hydrogel film, comprising the following steps:

[0072] Mix monomer, gelatin, crosslinking agent, initiator, photoinitiator and water to prepare mixed solution;

[0073] The mixed solution is coated on the substrate and reacted at 50-70° C. to prepare a hydrogel film.

[0074] The raw material cost of the above-mentioned hydrogel membrane is low, the preparation method is simple, and the large-scale production and application are easy.

[0075] In one embodiment, the reaction time is 10 min-30 min.

[0076] Alternatively, the substrate may be a watch glass.

[0077] Understandably, methyl methacrylate and methacrylic acid can undergo free radical polymerization at the above-mentioned temperature under the action of a crosslinking agent and an initiator to generate polymethyl methacrylate. Simultaneously, due to the ad...

Embodiment 1

[0082] This embodiment provides a hydrogel film and a preparation method thereof, the steps are as follows:

[0083]

[0084] 2) Preparation of hydrogel film

[0085] In a 500mL large beaker, mix the above-mentioned methyl methacrylate, methacrylic acid, gelatin, N,N'-methylenebisacrylamide, potassium persulfate, photoinitiator 2959 and deionized water to obtain a mixed solution ;

[0086] Coat the mixed solution on a round watch glass, put it in an oven, and react at 60°C for 20 minutes. During this process, methyl methacrylate and methacrylic acid can be converted into Under the action of amide, potassium persulfate and photoinitiator 2959, a free radical polymerization reaction occurs to generate polymethyl methacrylate. At the same time, due to the addition of gelatin, it can be compounded with polymethyl methacrylate to obtain gelatin / polymethyl methacrylate Methyl acrylate composite hydrogel.

[0087] Soak the gelatin / polymethyl methacrylate composite hydrogel in d...

Embodiment 2

[0089] This embodiment provides a hydrogel film and a preparation method thereof, the steps are as follows:

[0090] 1) Weigh the following raw materials

[0091]

[0092]

[0093] 2) Preparation of hydrogel film

[0094] In a 500mL large beaker, mix the above-mentioned methyl methacrylate, methacrylic acid, gelatin, N,N'-methylenebisacrylamide, potassium persulfate, photoinitiator 2959 and deionized water to obtain a mixed solution ;

[0095] Coat the mixed solution on a round watch glass, put it in an oven, and react at 60°C for 20 minutes. During this process, methyl methacrylate and methacrylic acid can be converted into Under the action of amide, potassium persulfate and photoinitiator 2959, a free radical polymerization reaction occurs to generate polymethyl methacrylate. At the same time, due to the addition of gelatin, it can be compounded with polymethyl methacrylate to obtain gelatin / polymethyl methacrylate Methyl acrylate composite hydrogel.

[0096] Soak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com