Intravascular stent and preparation method thereof

A vascular stent and vascular endothelial technology, applied in the field of medical devices, can solve the problems of artificial blood vessel thrombosis, long operation time, and strict medical conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a stent, comprising the following steps:

[0034] A nonionic surfactant solution and a polymer solution are provided; the polymer solution includes a thermally induced shape memory polymer and a vascular endothelial growth factor;

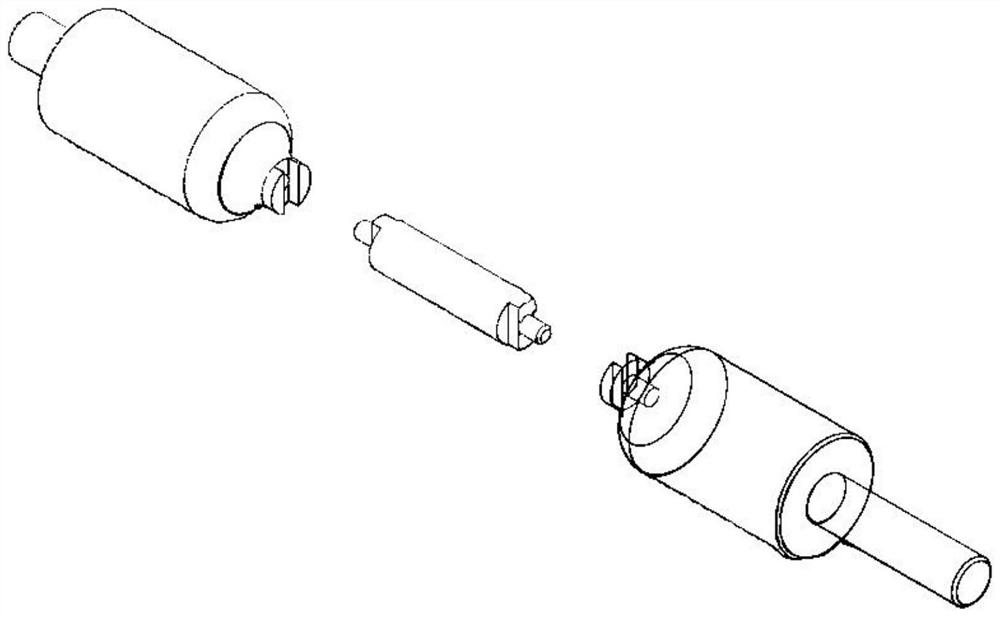

[0035] performing a first electrospinning of the nonionic surfactant solution to obtain a tubular water-soluble template fiber membrane;

[0036] Using the tubular water-soluble template fiber membrane as a receiving substrate, performing a second electrospinning of the polymer solution to obtain a first stent precursor;

[0037] After removing the nonionic surfactant in the first stent precursor, cross-link mTG enzyme to obtain the second stent precursor;

[0038] Loading heparin on the inner wall of the second vascular stent precursor to obtain the vascular stent.

[0039] In the present invention, unless otherwise specified, all preparation materials are commercially available products well ...

Embodiment 1

[0113] Pluronic F127 (M w =12,600Da) and deionized water were mixed, and magnetically stirred for 2 hours in an environment of 4°C to obtain a Pluronic F127 hydrogel solution with a concentration of 35wt%;

[0114] Put 12g of polyε-caprolactone diol into a three-necked flask filled with nitrogen after drying by rotary evaporation, and put it into an oil bath at 60°C for 1 hour under the condition of stirring to completely melt the polyε-caprolactone diol , lowered to room temperature, added 1.5mL hexamethylene diisocyanate, heated to 60°C, stirred for 3h, added 4mL isophorone diisocyanate and 12mL dimethyl carbonate, stirred for 30min, added 0.05mL dibutyltin dilaurate , a prepolymerization reaction occurs for 1 hour to obtain a prepolymer;

[0115] 1.6 mL of 1,4-butanediol was added to the prepolymer, and a chain extension reaction occurred for 4 hours to obtain polyurethane;

[0116] Mix the polyurethane and 12mL dimethyl carbonate to obtain a polyurethane solution, pour i...

Embodiment 2

[0125] Mix 1.0g of PVP and 9.0g of ethanol and stir for 3h to obtain the ethanol solution of PVP;

[0126] Put 12g of polyε-caprolactone diol into a three-necked flask filled with nitrogen after drying by rotary evaporation, and put it into an oil bath at 60°C for 1 hour under the condition of stirring to completely melt the polyε-caprolactone diol , lowered to room temperature, added 1.5mL hexamethylene diisocyanate, heated to 60°C, stirred for 3h, added 4mL isophorone diisocyanate and 12mL dimethyl carbonate, stirred for 30min, added 0.05mL dibutyltin dilaurate , a prepolymerization reaction occurs for 1 hour to obtain a prepolymer;

[0127] 1.6 mL of 1,4-butanediol was added to the prepolymer, and a chain extension reaction occurred for 4 hours to obtain polyurethane;

[0128] Mix the polyurethane and 12mL dimethyl carbonate to obtain a polyurethane solution, pour it into a polytetrafluoroethylene mold, and put it into a vacuum oven for curing. The curing temperature is 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

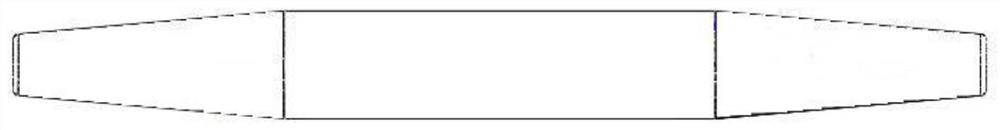

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com