Chemical fiber industry plan production scheduling method and system

A production system and planning technology, applied in the direction of manufacturing computing systems, computing, instruments, etc., can solve problems such as inaccurate machine scheduling, poor timeliness and sharing of production information, and no standardized production management process, so as to improve management efficiency and Production efficiency, smooth completion of production tasks, and the effect of improving tracking management capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

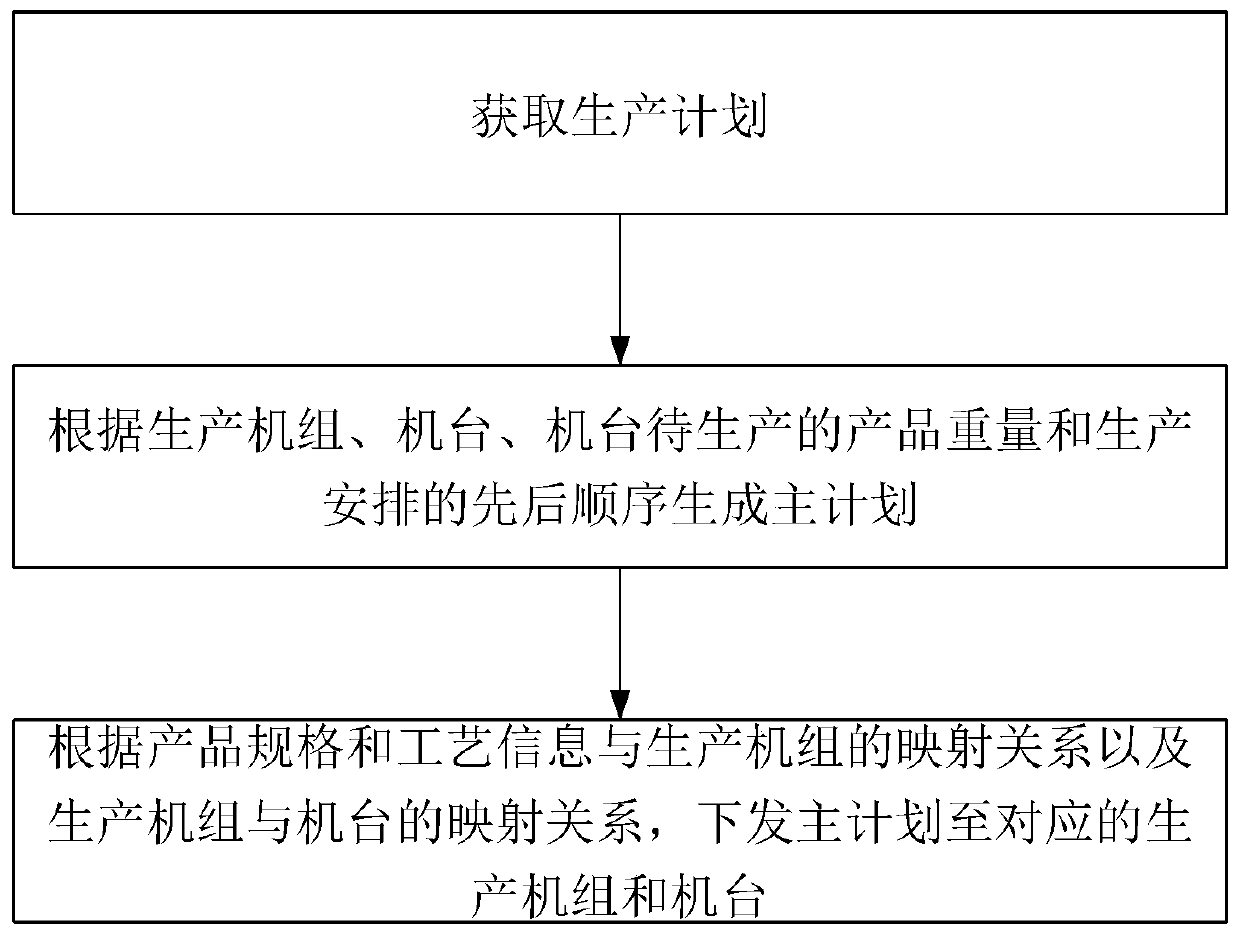

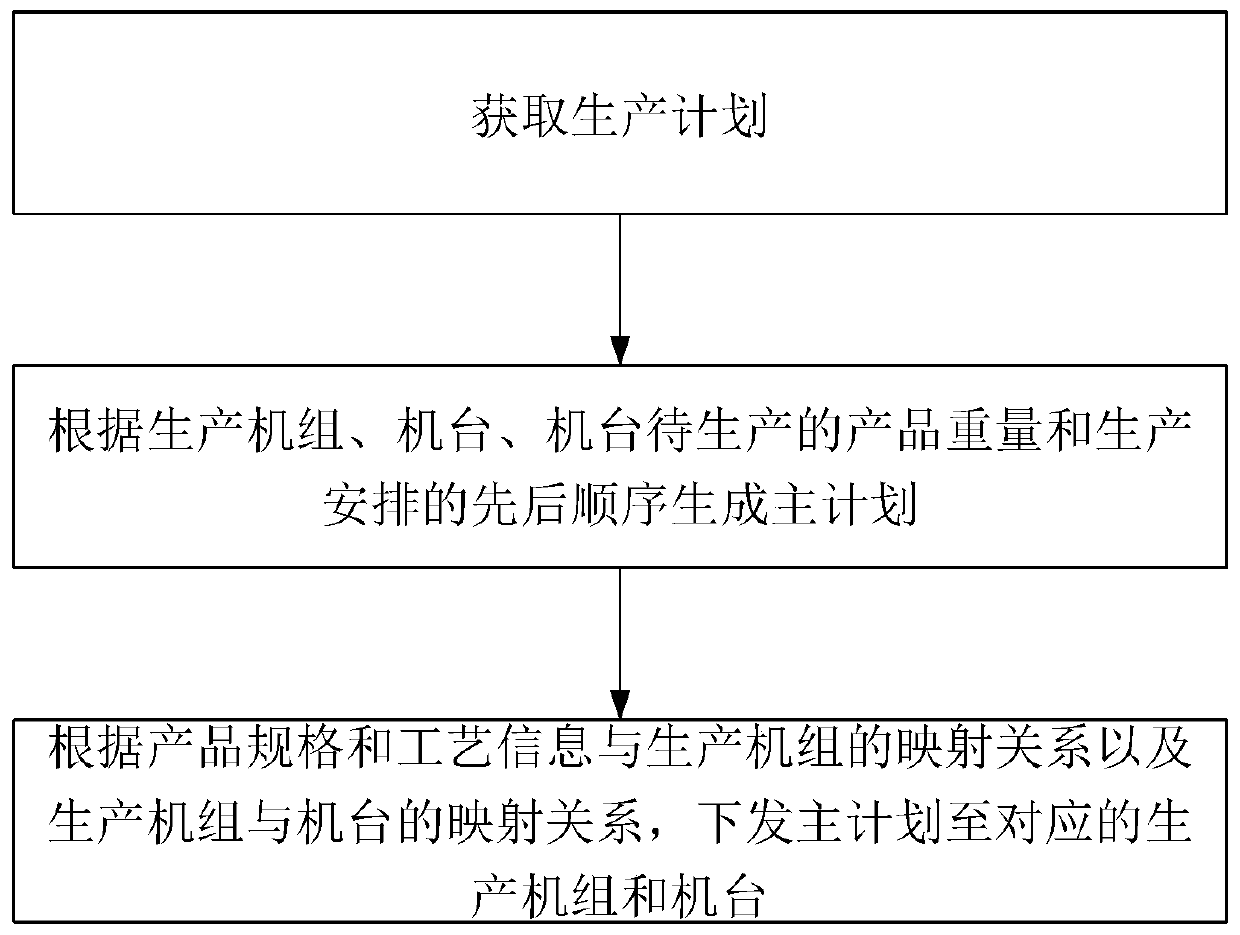

[0035] Through the following examples, combined with the attached Figure 1-2 , the technical solution of the present invention will be further specifically described.

[0036] as attached figure 1 As shown, the present invention provides a method for planning and scheduling production in the chemical fiber industry. The production tasks are allocated according to the production plan through the automatic production scheduling system, including the following steps:

[0037] Obtain the production plan, which includes the production batch number, estimated output, planned start and end time, and plan type; the production plan is imported through the ERP system or entered into the system by the planner.

[0038] Among them, the production batch number includes product specification information, process information, material code and material BOM information. The production batch number needs to be obtained by the ERP system after maintenance in the ERP system; for the newly esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com