Composite photocatalytic material and preparation method and application thereof

A composite photocatalysis and oxide technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited reaction active sites, insufficient catalytic efficiency, difficult separation, etc. The effect of light energy utilization and photocatalytic efficiency, excellent electron transport performance, and fast mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a method for preparing a composite photocatalytic material, the steps are as follows:

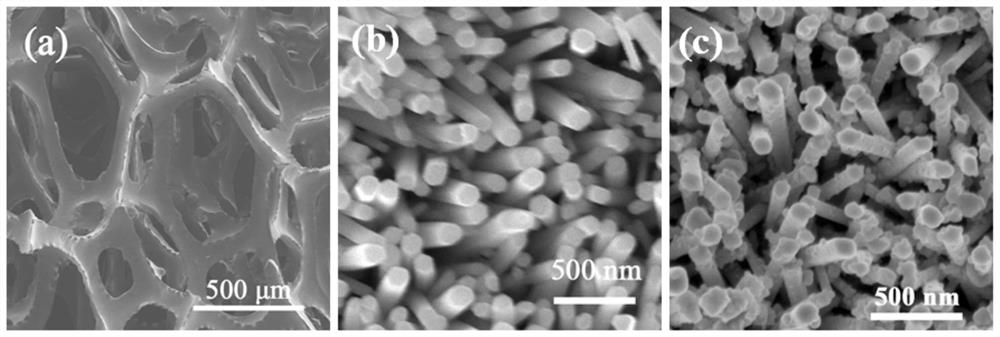

[0053] (1) Porous carbon foam (scanning electron microscope picture as figure 1 As shown in a) cut into 3cm×3cm size, ultrasonic cleaning in 2mol / L nitric acid, 1.5mol / L acetone, absolute ethanol and deionized water in sequence, each solvent was cleaned for 15 minutes (power 100W), and dried naturally;

[0054] (2) prepare respectively the ethanol solution of tungsten hexachloride, the aqueous solution of sodium tungstate, platinum nitrate solution and sodium citrate solution, wherein, the molar concentration of tungsten salt in the ethanol solution of tungsten hexachloride is 0.02mol / L, will The ethanol solution of tungsten hexachloride and the hydrogen peroxide solution are mixed according to the volume ratio of 10:1 to obtain the mixed solution of the ethanol solution of tungsten hexachloride and the hydrogen peroxide solution; the molar concentration of t...

Embodiment 2

[0059] This embodiment provides a method for preparing a composite photocatalytic material, the steps are as follows:

[0060] (1) Porous carbon foam (scanning electron microscope picture as figure 1 As shown in a) cut into 3cm×3cm size, ultrasonic cleaning in 1mol / L nitric acid, 1mol / L acetone, absolute ethanol and deionized water in sequence, each solvent was cleaned for 15 minutes (power 50W), and dried naturally;

[0061] (2) prepare ethanol solution of zinc acetate, zinc nitrate aqueous solution, hexamethylenetetramine solution, silver nitrate solution and sodium citrate solution respectively, wherein, the molar concentration of zinc salt in the ethanol solution of zinc acetate is 0.01mol / L The molar concentration of the zinc nitrate aqueous solution is 10mmol / L, and the molar concentration of the hexamethylene tetraammonium solution is 8mmol / L, and the zinc nitrate aqueous solution and the hexamethylene tetraammonium solution are mixed according to a volume ratio of 1:2 ...

experiment example 1

[0066] This experimental example is used to verify the removal effect of the composite photocatalytic material prepared in Example 1 on bisphenol A (PBA) and heptavalent manganese (Mn(VII)) in drinking water. The composite photocatalytic material prepared in Example 1 is used as the experimental object, denoted as Pt / WO 3 / CF group. As a contrast, the load WO 3 Carbon foam of nanowire arrays (denoted as WO 3 / CF group) and the porous carbon foam (referred to as CF group) obtained by the step (1) of Example 1 for experimentation. The experimental method is as follows:

[0067] Take 3 parts of drinking water samples to be treated containing 20mg / L BPA (recorded as drinking water sample 1), 3 parts of drinking water samples to be treated containing 20mg / L Mn(VII) (recorded as drinking water samples 2), 3 parts of drinking water samples containing 20mg / L Mn(VII) Part of the drinking water sample (recorded as drinking water sample 3) containing 20mg / L BPA and 20mg / L Mn(VII) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com