Premixed mortar suitable for plastering of various walls and preparation method thereof

A ready-mixed mortar and wall technology, applied in the field of mortar, can solve the problems of low adhesion rate, poor effect, inability to adapt to complex use environments, etc., achieve good adhesion performance, and increase the effect of impermeability and crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

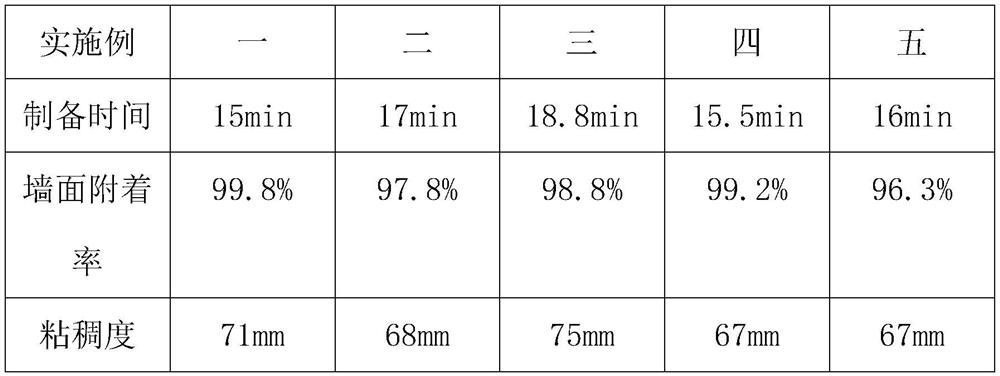

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

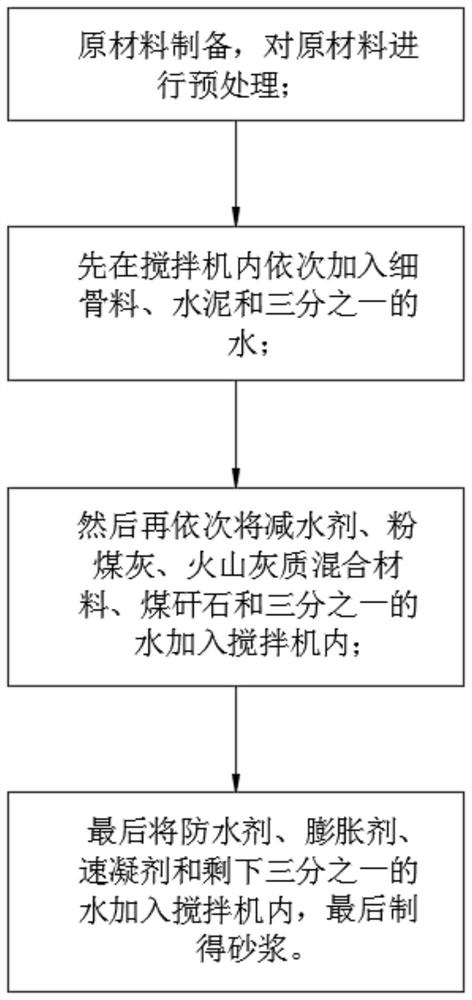

[0024] refer to figure 1 , embodiment one

[0025] In this embodiment, a ready-mixed mortar suitable for plastering various walls and a preparation method thereof are proposed, including the following raw materials: 26 parts of water, 18 parts of cement, 40 parts of fine aggregate, 12 parts of fly ash, 6 parts of pozzolanic mixed material, 2 parts of coal gangue, 7 parts of waterproofing agent, 4 parts of water-reducing agent, 7 parts of expansion agent, and 4 parts of quick-setting agent.

[0026] Include the following steps:

[0027] S1: Raw material preparation, pretreatment of raw materials, concrete is 42.5R Portland cement, fine aggregate is specifically made by mixing machine-made sand and river sand at 1:3, and the mixing ratio of pozzolan ash is 8:4: 1 is made by mixing volcanic ash, silica and alumina. It is necessary to put the machine-made sand and coal gangu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com