A kind of preparation method and solid method of ceramic slurry

A technology of ceramic slurry and ceramic powder, which is applied in the field of ceramics, can solve the problems of unfavorable manufacturing of ceramic electronic devices, complex photocuring process engineering, easy cracks or deformation, etc., so as to accelerate the photocuring molding process and shorten the surface solidification time , enhance the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

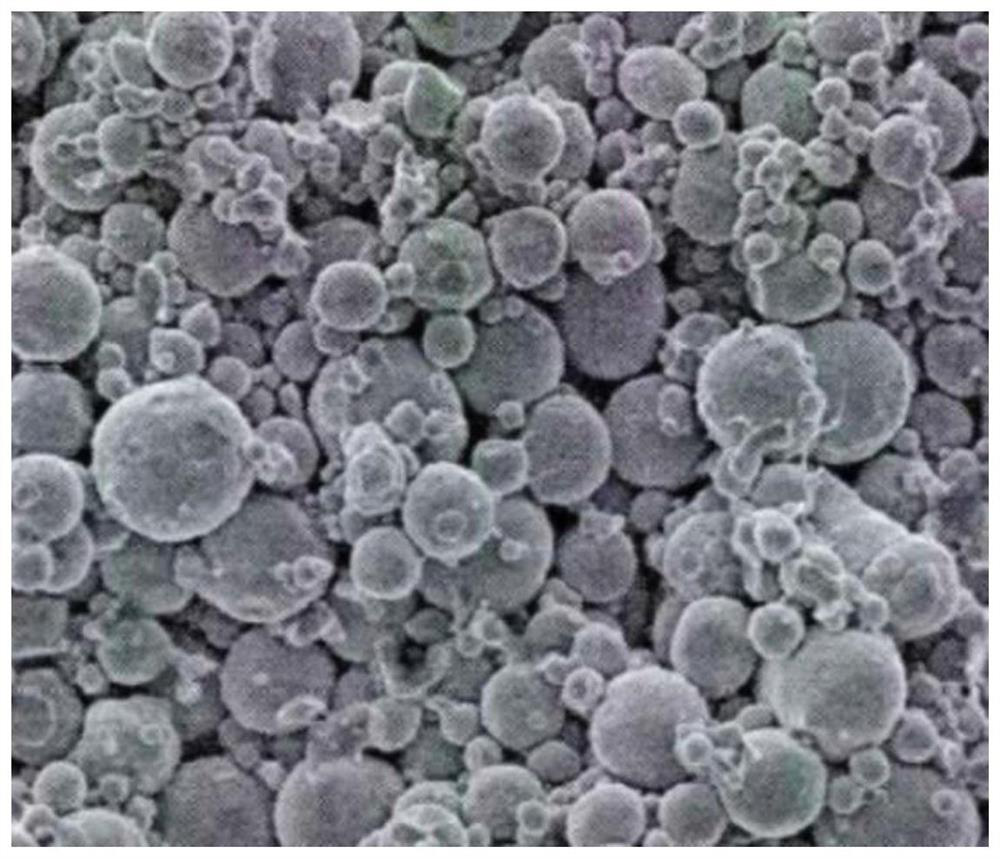

Image

Examples

Embodiment 1

[0026] Step 1: Mix and ball mill 3vol% oxides, the oxides include oxide A and oxide B, add 18vol% photosensitive resin and 2vol% additives, stir and mix, add 77vol% ceramic powder, stir and homogenize, and obtain a solid content of 82% ceramic slurry.

[0027]Step 2: Set the light-curing wavelength to 400nm, and print the ceramic slurry layer by layer through a DLP-type light-curing 3D printer. Dry in an oven at 60°C for 2 hours, transfer to a debinding furnace with an inert atmosphere, and heat up to 500°C at a heating rate of 2°C / min under the irradiation of an ultraviolet lamp with a wavelength of 400nm; Degrease for 1 hour; dry again, transfer to a vacuum or inert gas sintering furnace, and sinter at a controlled temperature to obtain a ceramic product.

[0028] In this scheme, oxide A is 10nm SiO 2 ;Oxide B is 20nm TiO 2 . Photosensitive resin urea-formaldehyde resin. Ceramic powder is 250nm Al 2 o 3 And alkali metal titanate mixture, under UVA conditions, the spec...

Embodiment 2

[0030] Step 1: Mix and ball mill 4vol% oxides, the oxides include oxide A and oxide B, add 45vol% photosensitive resin and 1vol% additives, stir and mix, add 50vol% ceramic powder, stir and homogenize, and obtain a solid content of 55% ceramic slurry.

[0031] Step 2: Set the light-curing wavelength to 400nm, and print the ceramic slurry layer by layer through an SLA-type light-curing 3D printer. Dry in an oven at 60°C for 2 hours; transfer to a debinding furnace with an inert atmosphere, and under the irradiation of a UV lamp with a wavelength of 400nm, the temperature rises at a rate of 2°C / min to 500°C; hour, degrease; dry again, transfer to vacuum or inert gas sintering furnace, temperature control sintering, to obtain ceramic products.

[0032] In this scheme, oxide A is 5nm Al 2 o 3 ;Oxide B is 15nm TiO 2 . The photosensitive resin is polyaldehyde resin. The ceramic powder is alkali metal titanate with a thickness of 100 nm, and the spectral light transmittance is ...

Embodiment 3

[0034] Step 1: Mix and ball mill 1vol% oxides, the oxides include oxide A and oxide B, add 10vol% photosensitive resin and 4vol% additives, stir and mix, add 85vol% ceramic powder, stir and homogenize, and obtain a solid content of 85% ceramic slurry.

[0035] Step 2: Set the light-curing wavelength to 300nm, and print the ceramic slurry layer by layer through a DLP-type light-curing 3D printer. Dry in an oven at ℃ for 1 hour, transfer to a debinding furnace with an inert atmosphere, use an oxalic acid catalyst under the irradiation of a UV lamp with a wavelength of 300nm, and set the temperature at 150℃ to degrease; dry again, and transfer to vacuum or inert gas In a sintering furnace, the temperature is controlled and sintered to obtain ceramic products.

[0036] In this scheme, oxide A is 20nm SiO 2 、Al 2 o 3 , ZrO 2 One or more of , CaO, MgO; oxide B is 40nm silicon dioxide surface-modified TiO 2 . The photosensitive resin is polyaldehyde resin. Ceramic powder is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com