Component-controllable Bi-Te-Se ternary nanowire and preparation method thereof

A nanowire and te-se technology, which is applied in the field of Bi-Te-Se ternary nanowires with controllable components and their preparation, can solve the problem that bismuth telluride is difficult to meet the needs of commercial applications, and achieve potential application value. , the effect of stable structure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

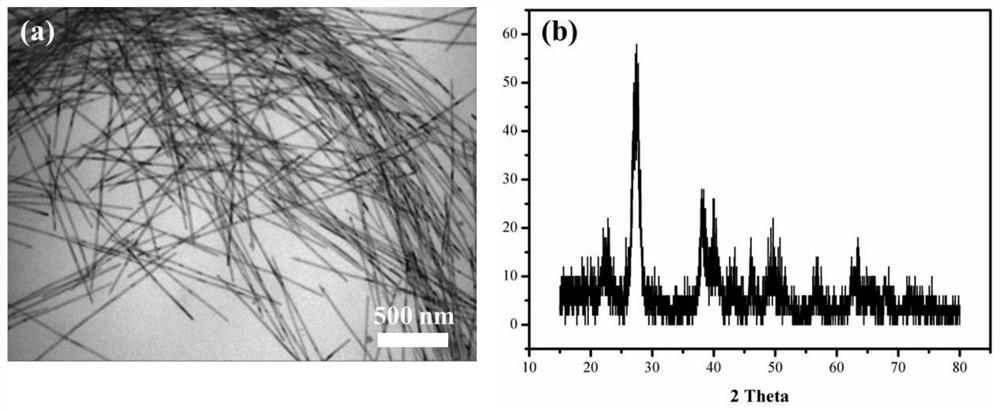

[0036] Step 1. Preparation of Te nanowires: First, mix and dissolve 1.5mmol of tellurium oxide, 0.75g of polyvinylpyrrolidone and 10mmol of potassium hydroxide in 30mL of ethylene glycol, use magnetic stirring to make it evenly mixed, and then mix The solution was poured into a three-necked bottle, and under the conditions of nitrogen protection, circulating water cooling and magnetic stirring, the mixed solution was heated to 140°C, and 4 mL of hydrazine hydrate with a concentration of 85% was quickly injected. For solution A of elemental nanowires, lower the temperature of the solution to 90°C for use;

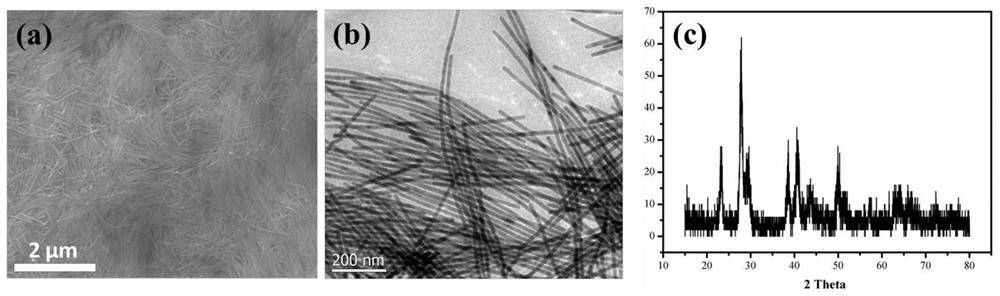

[0037] The preparation of step 2.Te-Se nanowires: (0.17-1.5)mmol selenous acid, the concentrated hydrochloric acid of (2.5-5)mL and (0.5-1)g polyvinylpyrrolidone that concentration is 18mol / L are dissolved in 10mL of ethylene glycol, and use magnetic stirring for 3–5min to make it evenly mixed. Then it is injected into the Te nanowire solution at 90°C in step 1 through a sy...

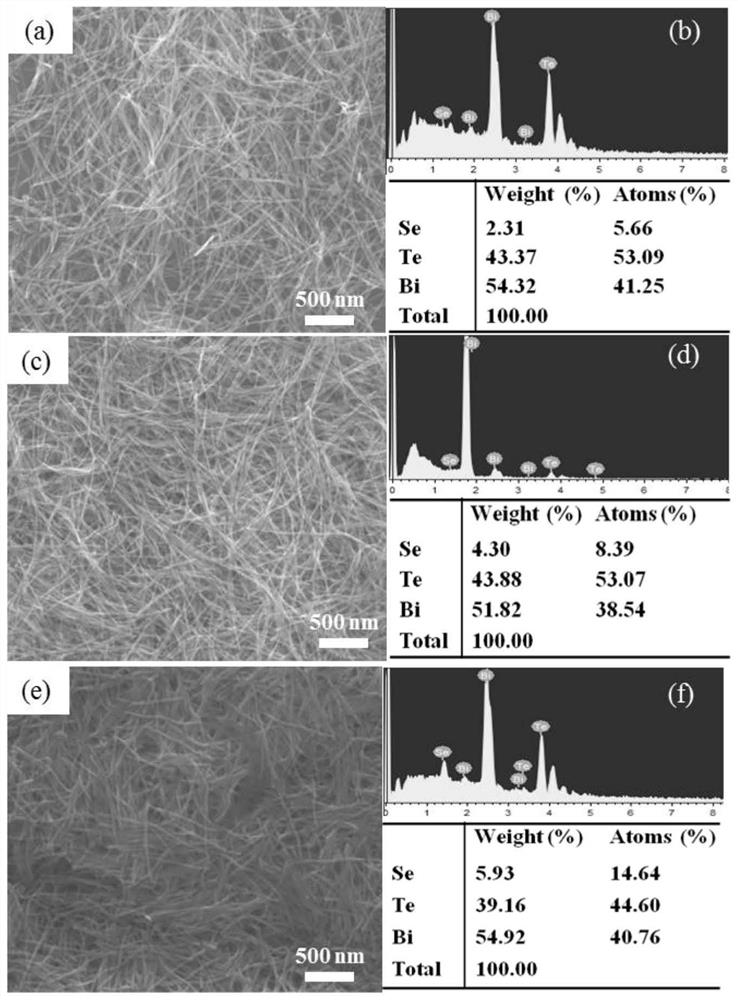

Embodiment 1

[0040] First, 0.2394g (1.5mmol) of TeO 2, 0.75g PVP and 5.6g (10mmol) KOH, mixed and dissolved in 30ml EG at room temperature, and fully dissolved into a transparent liquid by magnetic stirring. Then pour it into a 100ml three-neck bottle, under the conditions of nitrogen protection, circulating water cooling and magnetic stirring, heat the mixed solution to 140°C, quickly inject 4ml of hydrazine hydrate through a syringe, and keep it warm for 1 hour to obtain Te solution of nanowires. Lower the temperature of the solution to 90°C for use;

[0041] 0.0215g (0.17mmol) selenous acid (H 2 SeO 3 , 99.99%), 2.5ml of concentrated hydrochloric acid (HCl, 18mol / L) and 0.5g of PVP were dissolved in 10mL of ethylene glycol, and the solution was magnetically stirred at room temperature for 3-5min until the solute was completely dissolved and the solution appeared colorless Transparent, it is injected into the tellurium nanotube solution at a temperature of 90°C, then the temperature ...

Embodiment 2

[0048] First, 0.2394g (1.5mmol) of TeO 2 , 0.75g PVP and 5.6g (10mmol) KOH were mixed and dissolved in 30mL EG at room temperature, and fully dissolved into a transparent liquid by magnetic stirring. Then pour it into a 100ml three-necked bottle, under the conditions of nitrogen protection, circulating water cooling and magnetic stirring, heat the mixed solution to 140°C, quickly inject 4mL of hydrazine hydrate through a syringe, and keep warm for 1 hour to obtain Te For the solution A of the nanowires, the temperature of the solution is lowered to 90°C for use;

[0049] 0.0323g (0.25mmol) selenous acid (H 2 SeO 3 , 99.99%), 3ml of concentrated hydrochloric acid (HCl, 18mol / L) and 0.6g of PVP were dissolved in 10ml of ethylene glycol, and the solution was magnetically stirred at room temperature for 3-5min until the solute was completely dissolved and the solution appeared colorless and transparent shape, inject it into a solution of tellurium nanotubes at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com