Full-scale fiber grating piezoelectric tuning multi-gas sensing system and spectrum analysis method

A fiber grating, gas sensing technology, applied in the measurement of color/spectral properties, material analysis by optical means, measurement devices, etc., can solve the problems of limited application, limited magnification, and many components, and achieve high sensitivity It has the effect of high-precision detection, high spectral precision, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

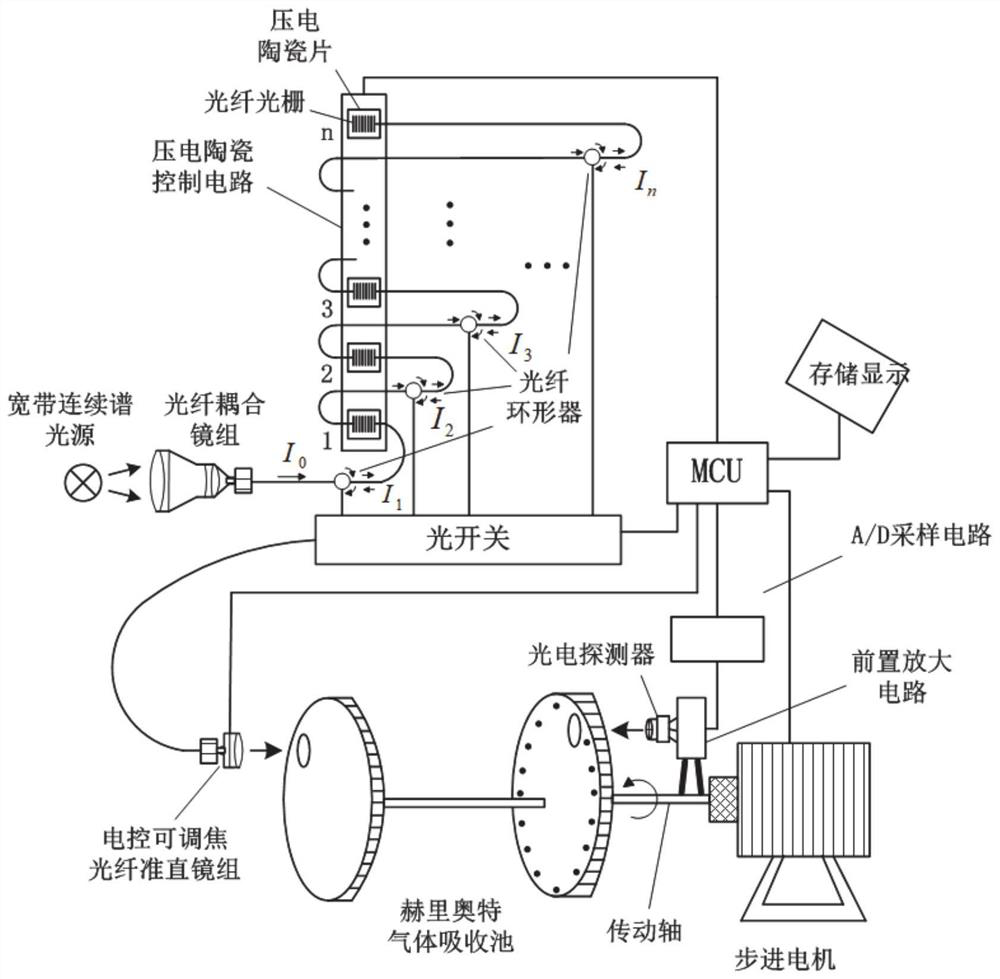

[0038] According to an embodiment of the present invention, a full-scale fiber grating piezoelectric tuning multi-gas sensing system is disclosed, such as figure 2 As shown, including: broadband continuum light source, fiber coupling mirror group, multiple fiber circulators, multiple fiber gratings, multiple piezoelectric ceramic sheets, piezoelectric ceramic control circuit, optical switch, fiber optic collimator mirror group, special Herriott gas absorption cell, stepper motor, photodetector and auxiliary preamplifier circuit, A / D sampling circuit, microcontroller (MCU) and storage display system and other component modules.

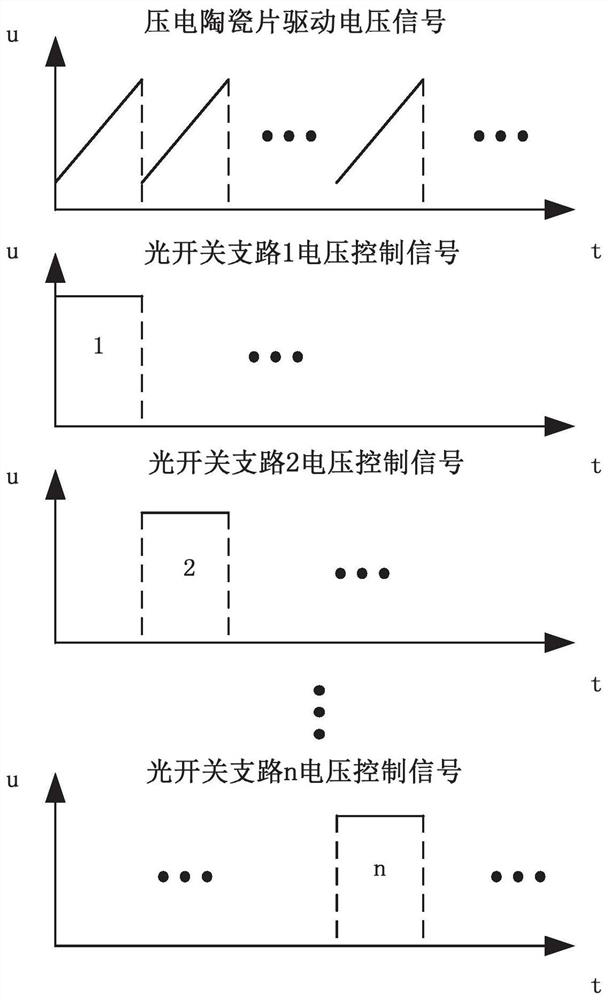

[0039] Specifically, the fiber-coupled mirror group is achromatic, and the mirror group is fixedly connected to the FC / APC connector of the fiber jumper through a threaded structure; multiple fiber gratings and fiber circulators are connected to each other through optical fibers; each fiber grating is glued to a press On the electric ceramic sheet, an...

Embodiment 2

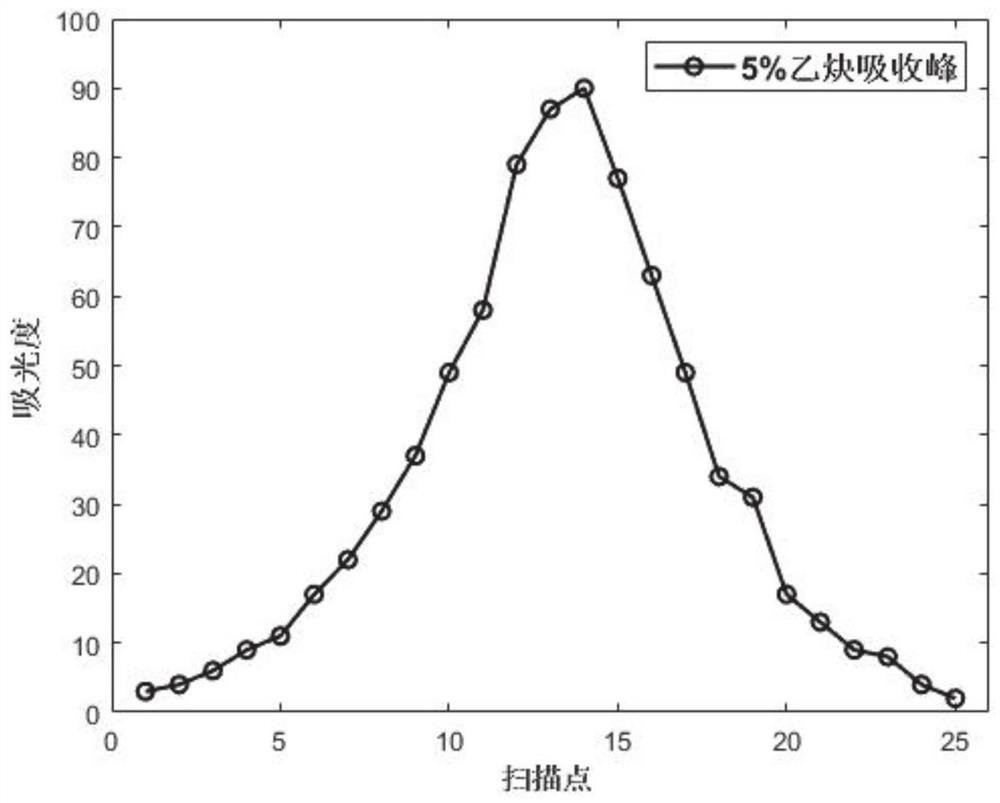

[0057] In one or more embodiments, a spectral analysis method for a full-scale fiber grating piezoelectric tuning multi-gas sensing system is disclosed. The acquired raw scan spectra were analyzed. For example, for branch n, when branch n is open and all other branches are closed, the microcontroller will obtain a set of original spectral data in the complete scanning period of the piezoelectric ceramic chip, and analyze it based on the algorithm. For the acquired set of raw spectral data S 0 , assuming the spectral data S 0 contains m spectral intensity sampling points, which is an m-dimensional vector. Preset queue data structure S, S', S 1 with S 2 . The preset threshold e is certain positive floating-point data. The steps of the parsing algorithm are as follows:

[0058] (1) Set the value of e, define the queue data structure S, S', S 1 with S 2 ;

[0059] (2) Search for each element S in the original spectral data from small to large 0 [i], find the spectral da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com