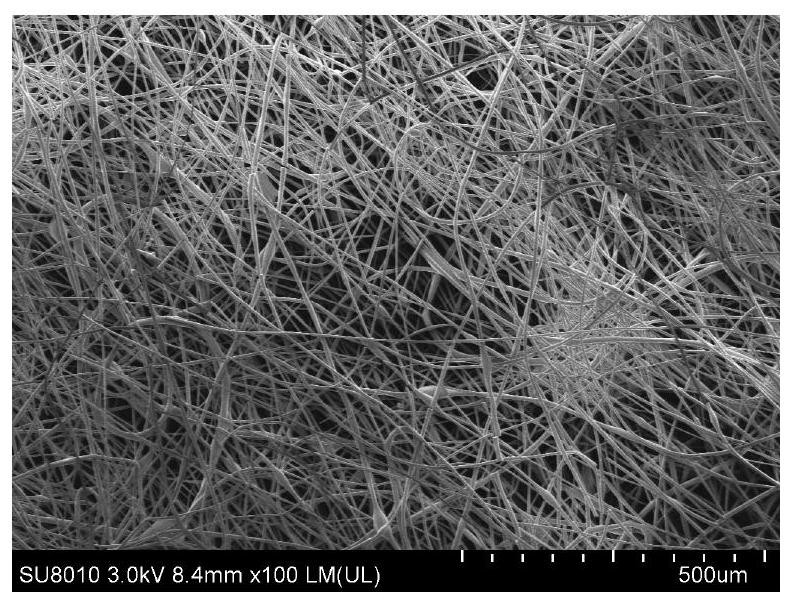

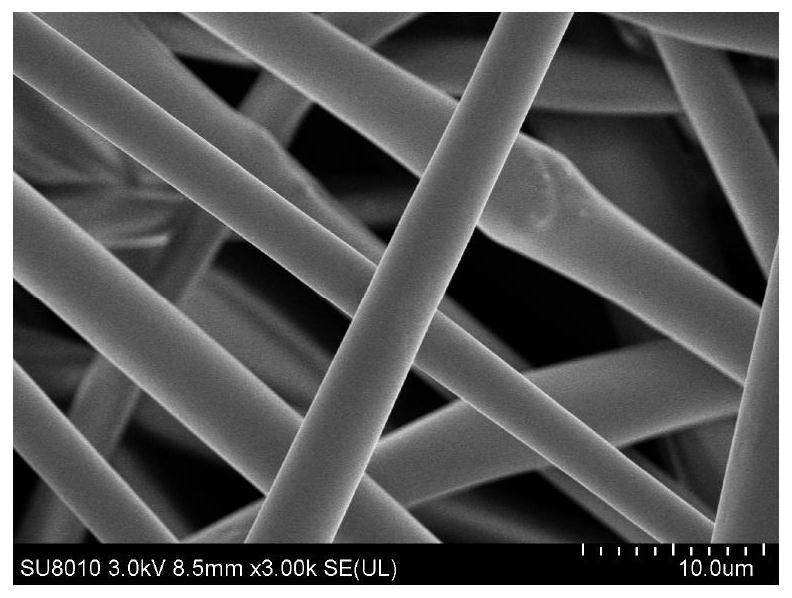

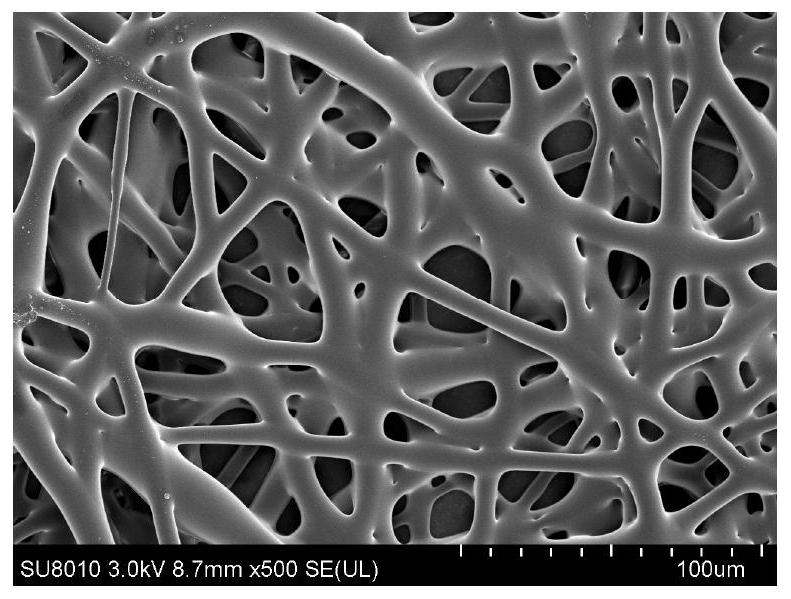

Graphene/polysiloxane spun fiber membrane and preparation method thereof

A technology of polysiloxane spinning and polysiloxane is applied in the field of graphene/polysiloxane spinning fiber film and its preparation, and can solve the problem of difficult fibers, low crystallinity, and secondary valence between polymer chains. problems such as small force, to achieve the effects of mild reaction conditions, simple preparation method and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of graphene / polysiloxane spinning fiber film, comprises steps:

[0043] Add 5.0g graphene to 10.0mL tetrahydrofuran solution of methyltrimethoxysilane with a concentration of 5mg / mL, ultrasonically disperse and mix evenly, then stir and react at 50°C for 24.0h to obtain a graphene suspension; add 160.0g formazan Dimethyldiethoxysilane and 10.0g dimethyldiethoxysilane were mixed evenly, and the graphene oxide suspension prepared above was added, ultrasonically dispersed, stirred until a uniform dispersion was formed, and the weight percentage concentration was 10.0wt%. dilute hydrochloric acid aqueous solution until the reactant system pH = 3.0. React at 80°C for 6h, then decompress and remove the low molecular weight for 1.0h at a vacuum of 10mmHg and a temperature of 90°C to obtain a polysiloxane prepolymer (liquid resin); by controlling the above polycondensation reaction conditions and decompression decompression In addition to low molec...

Embodiment 2

[0046] A kind of preparation method of graphene / polysiloxane spinning fiber film, comprises steps:

[0047] Add 35.0 g of graphene to 40.0 mL of phenyltrimethoxysilane toluene solution with a concentration of 15 mg / mL, ultrasonically disperse and mix evenly, and then stir and react at 60° C. for 30.0 h to obtain a graphene suspension. Mix 140.0g of phenyltrimethoxysilane with 100.5g of γ-mercaptopropylmethyldiethoxysilane evenly, add the graphene oxide suspension prepared above, ultrasonically disperse, stir rapidly until a uniform dispersion is formed, add weight Dilute hydrochloric acid aqueous solution with a percentage concentration of 10.0 wt%, until the pH of the reactant system is 2.0. React at 60°C for 12.0h, then remove low molecules under reduced pressure for 1.2h at a vacuum of 10mmHg and a temperature of 110°C to obtain a polysiloxane prepolymer (liquid resin). Using toluene as a solvent, the prepolymer was formulated into a prepolymer spinning solution with a con...

experiment example 3

[0049] A kind of preparation method of graphene / polysiloxane spinning fiber film, comprises steps:

[0050] Add 15.0 g of graphene to 20.0 mL of methyltriethoxysilane tetrahydrofuran solution with a concentration of 10 mg / mL, ultrasonically disperse and mix evenly, and then stir and react at 40° C. for 30.0 h to obtain a graphene suspension. Mix 105.0g of methyltrimethoxysilane and 50.0g of γ-chloropropylmethyldiethoxysilane evenly, add the graphene oxide suspension prepared above, ultrasonically disperse, stir rapidly until a uniform dispersion is formed, add dilute hydrochloric acid aqueous solution with a weight percent concentration of 10.0wt%, until the reactant system pH=4.0. React at 50°C for 8.0h, then remove low molecular weight under reduced pressure for 1.5h at a vacuum of 10mmHg and a temperature of 95°C to obtain a polysiloxane prepolymer (liquid resin). Using tetrahydrofuran as a solvent, the prepolymer was formulated into a prepolymer spinning solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com