Preparation method and application of hyperbranched polyacrylamide nano-microspheres for profile control and displacement of low-porosity and low-permeability oil reservoirs

A polyacrylamide and nano-microsphere technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of unsatisfactory effect of deep regulation and flooding in low-permeability oil reservoirs, unstable linear molecular chain structure, and shear resistance. Poor performance and other problems, to achieve the effect of improving the development effect of water injection, bright development prospects and economic benefits, and not easy to fracture and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

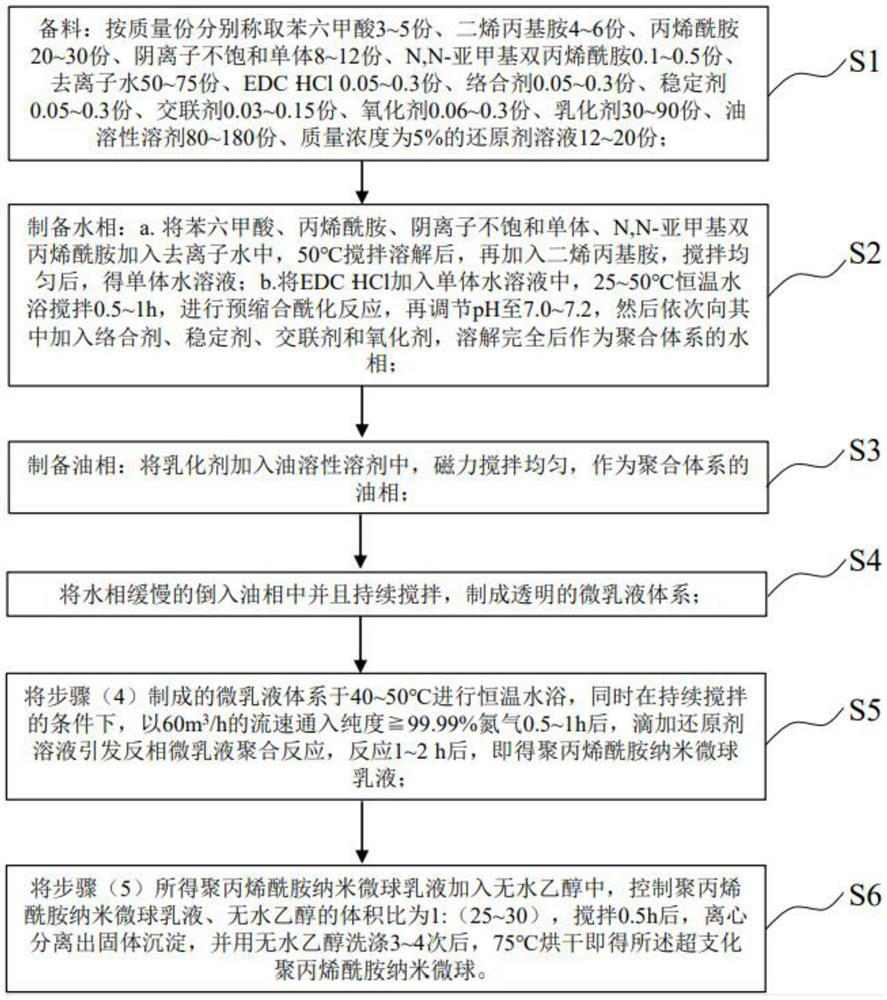

[0034] This example provides a method for preparing hyperbranched polyacrylamide nanospheres for control and flooding of low-porosity and low-permeability reservoirs. The hyperbranched polyacrylamide nanospheres use mellitic acid as a rigid structure branching Phase emulsion polymerization method, formed by copolymerization with diallylamine, acrylamide, anionic unsaturated monomer, N,N-methylenebisacrylamide, specifically including the following steps:

[0035] (1) Material preparation: Weigh 3-5 parts of mellitic acid, 4-6 parts of diallylamine, 20-30 parts of acrylamide, 8-12 parts of anionic unsaturated monomer, N,N- 0.1-0.5 parts of methylenebisacrylamide, 50-75 parts of deionized water, 0.05-0.3 parts of EDC·HCl, 0.05-0.3 parts of complexing agent, 0.05-0.3 parts of stabilizer, 0.03-0.15 parts of cross-linking agent, 0.06-0.3 parts of oxidizing agent, 30-90 parts of emulsifier, 80-180 parts of oil-soluble solvent, 12-20 parts of reducing agent solution; the mass concentr...

Embodiment 1

[0049] (1) Material preparation: Weigh 4.2g of mellitic acid, 4.7g of diallylamine, 25.2g of acrylamide, 10.8g of acrylic acid, 0.1g of N,N-methylenebisacrylamide, 55g of deionized water, EDC ·HCl 0.065g, sodium ethylenediamine tetramethylene phosphate 0.065g, polyvinylpyrrolidone 0.065g, pentaerythritol triacrylate 0.045g, sodium persulfate 0.13g, kerosene 110g, 40g span80+13.35g tween80, mass concentration 5% 16g of sodium bisulfite solution;

[0050] (2) Prepare the water phase:

[0051] a. Add mellitic acid, acrylamide, acrylic acid, and N,N-methylenebisacrylamide into deionized water, stir and dissolve at 50°C, then add diallylamine, and stir evenly to obtain an aqueous monomer solution;

[0052] b. Add EDC·HCl to the monomer aqueous solution, stir in a constant temperature water bath at 50°C for 0.5h, carry out pre-condensation acylation reaction, then adjust the pH to 7.0, and then add sodium ethylenediamine tetramethylene phosphate and polyvinylpyrrolidone to it in se...

Embodiment 2

[0066] Same as Example 1, except that 0.1g of N,N-methylenebisacrylamide is replaced by 0.05g of N,N-methylenebisacrylamide.

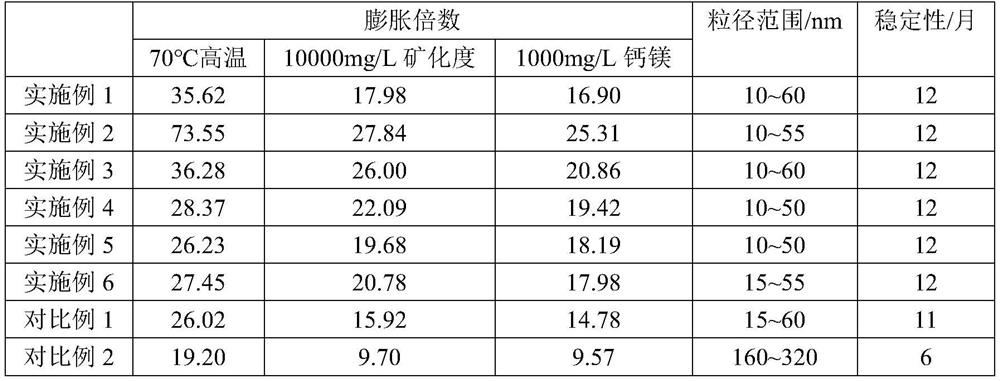

[0067] Expansion multiple test: Weigh 0.162g of hyperbranched polyacrylamide nanospheres into an 80-mesh nylon mesh filter bag, and completely immerse it in 250mL of 70°C high-temperature water; 0.169g of hyperbranched polyacrylamide nanospheres into 80-mesh nylon mesh filter bag, and completely immerse it in 250mL of 10000mg / L salinity solution; 0.105g hyperbranched polyacrylamide nano-microspheres are packed into 80-mesh nylon mesh filter bag, and completely immerse it in 250mL 1000mg / L calcium magnesium solution;

[0068] After 48 hours, the filter bag was taken out, and excess water on the surface of the microspheres was wiped off with filter paper, and the masses were said to be 12.078g, 4.874g, and 2.763g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com