Weldable Cast Superalloys and Their Applications

A superalloy and post-welding technology, applied in the field of casting superalloys, can solve the problem of not being able to balance high-temperature performance, mechanical properties, casting process performance, and welding performance at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0059] Examples 1 to 7 respectively provide weldable cast superalloys 1# to 7# and their preparation methods. Specifically, the weldable cast superalloys are prepared from the raw materials listed in Table 1 and their contents.

[0060] Table 1 Composition ratios of different weldable cast superalloys (mass percent %)

[0061]

[0062] Concrete preparation method comprises the following steps:

[0063] (1) Prepare the raw materials according to the composition content listed in Table 1 and the element ratio of the superalloy, and use the vacuum induction melting process to obtain ingots;

[0064] (2) The ingot was remelted in a vacuum induction melting furnace to prepare a corresponding weldable cast superalloy test rod.

[0065] The prepared test rods were heat treated respectively, and the heat treatment system was 1120°C×4h / air cooling+900°C×5h / air cooling.

experiment example 1

[0071] Characterize the microstructure of the test bar after the heat treatment obtained by 1#, 2# of the embodiment of the present invention, 2# and comparative examples of 8#, 9#, 10# and 14#, and the corresponding metallographic photographs are respectively as follows Figure 1~Figure 6 shown. It can be seen from the figure that when Mg and Ce elements are added to the alloy, the corners of the carbides precipitated at the grain boundaries of the alloy are relatively round and blunt, and are mainly distributed in an island chain shape, which improves the performance of the alloy to a certain extent.

[0072] Moreover, the microstructures of the solid solution state (1120°C×4h / air cooling) of some alloys in the examples and comparative examples of the present invention are as follows: in the 2# of the example, the large-grain precipitated phase accounts for 0.043%, of which 2μm~ The 5μm massive MC particles accounted for 0.02%~0.035% and the 5μm~10μm blocky μ phase accounted...

experiment example 2

[0079] Argon arc welding performance

[0080] Referring to the 1# alloy composition batch of Example 1, a test piece was made, and welded by argon arc welding, and the welding condition parameters were: welding current 80A, welding voltage 18V. Welded samples with a thickness of 2 mm were solution treated and then subjected to tensile tests, while unwelded test pieces with a thickness of 2 mm were taken for solution treatment and then subjected to tensile tests as the body comparative experimental data. The test results are shown in Table 4.

[0081] Table 4 Tensile properties of argon arc welding test piece and unwelded body at room temperature

[0082]

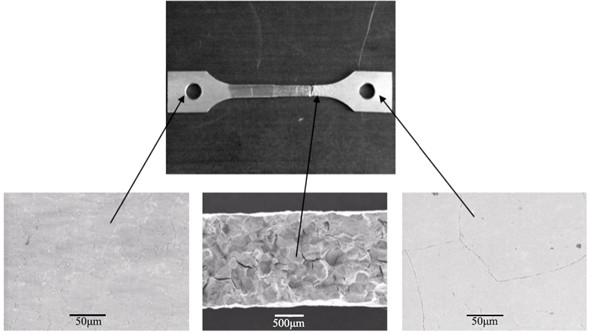

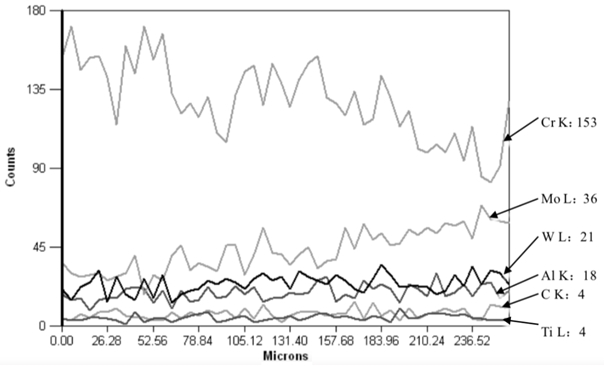

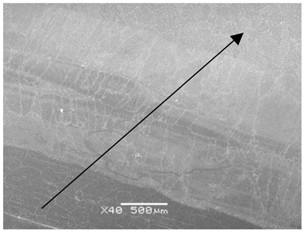

[0083] Figure 7 It is the metallographic structure diagram of the fracture of the sample after argon arc welding. It can be seen from the figure that the structure of the alloy weld is uniform, and the interface between the weld and the body is smooth. Figure 8 It is the scanning image of the energy spectrum of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com