a transformer

A technology of transformers and fixers, applied in the field of transformers, can solve the problems of small contact area between fins and heat, heat cannot be quickly diffused, and reduce the heat dissipation effect of fins, so as to improve the effect of heat dissipation and the effect of receiving heat , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

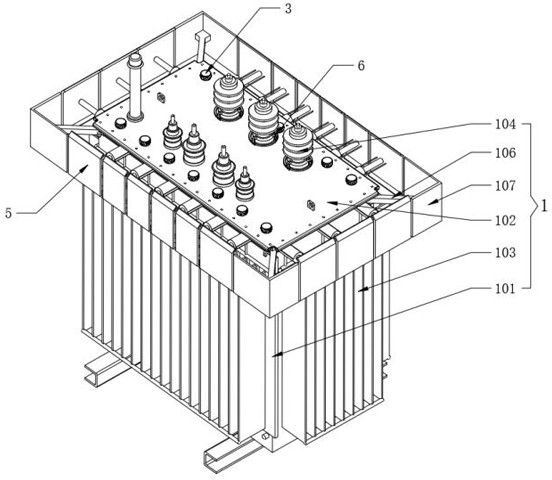

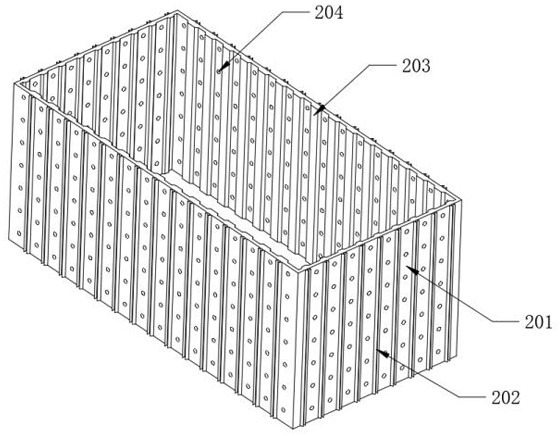

[0046] see figure 1 , 2 , a transformer, comprising, a transformer 1, a heat spreader 2 and a pneumatic cooling mechanism 3;

[0047] refer to figure 1 as well as figure 2, the transformer 1 also includes an outer body 101, an inner core 105 is fixedly installed inside the outer body 101, and the inner core 105 completes the work of voltage transformation after power-on, and the four side walls of the outer body 101 are fixedly provided with fin plates 103, and The main function of 103 is to dissipate heat. The top of the outer body 101 is fixedly assembled with a top board 102. The top board 102 is used to provide installation space for various wiring components and other circuit components. The upper surface of the top board 102 is equidistantly assembled with The terminal 104 and the four corners of the top board 102 are fixedly welded with side frame rods 106, and the other ends of the four side frame rods 106 are fixedly welded with corner guards 107, and the corner g...

Embodiment 2

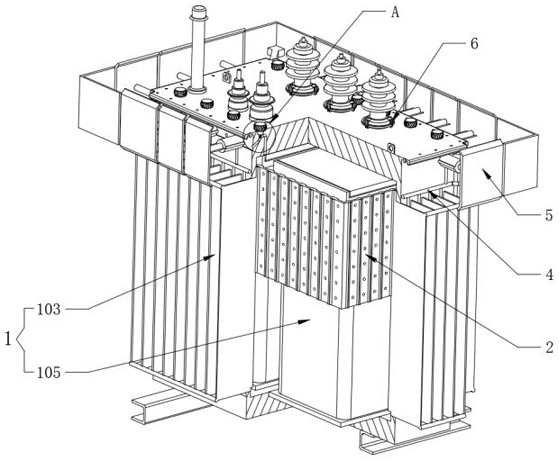

[0053] see Figure 5 , 6 , a transformer, comprising, a gap clearing structure 4 and a multifunctional anti-shock structure 5;

[0054] refer to Figure 5 and Figure 6 The top outer wall of the outer body 101 is provided with a gap clearing structure 4, the gap clearing structure 4 also includes a main air pipe 401, the main air pipe 401 is fixedly sleeved on the top outer wall of the outer body 101, and the lower surface of the main air pipe 401 is equidistantly fixedly connected with an air jet pipe 402, A single air jet tube 402 is respectively arranged in the space between the fin plates 103 , and one air jet tube 402 is set in every space between two fin plates 103 .

[0055] refer to Figure 6 and Figure 7 , the multi-functional anti-collision structure 5 also includes an outer tube 501, which is equidistant and fixedly installed on the top of the outer wall of the outer body 101, and an inner rod 503 is movably installed inside the outer tube 501, and one end of ...

Embodiment 3

[0058] see Figure 8 and Figure 9 , a transformer, comprising, a terminal holder 6;

[0059] refer to Figure 8 and Figure 9 , the terminal holder 6 is sleeved on the bottom end of the outer surface of the terminal 104, the terminal holder 6 also includes a lifting ring 604, the bottom edge of the terminal 104 is equidistantly equipped with a swivel 601, and the inside of the swivel 601 is connected by rotation. There is a clamping rod 602, the bottom end of the clamping rod 602 can be rotated with the body 601 as the center of a circle, the top of the clamping rod 602 is fixedly equipped with a clamping block 603, the inside of the clamping rod 602 is fixed with a guide groove 605, and the inner wall of the lifting ring 604 is equidistant Embedded with embedded rods 606, the embedded rods 606 are movably arranged inside the guide groove 605, and the inner wall of the top of the guide groove 605 is fixedly provided with a block 607, and the lifting ring 604 is manually li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com