Isothermal quenching nodular cast iron material and preparation method and application thereof

A nodular cast iron, austempering technology, applied in metal material coating process, transportation and packaging, coating, etc., can solve the problems of less than 1100MPa tensile strength, high alloy content of nodular cast iron, complex austempering process, etc., to achieve Improve the uniformity of the matrix structure, reduce the stress deformation of the workpiece, and reduce the effect of micro-segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a first aspect, the present invention provides a method for preparing an austempering ductile iron material, comprising the steps of:

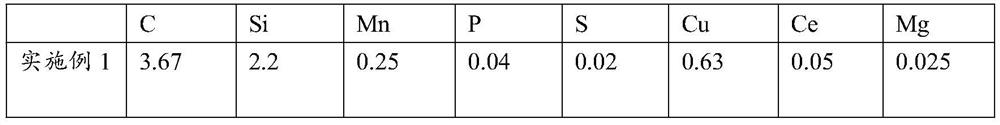

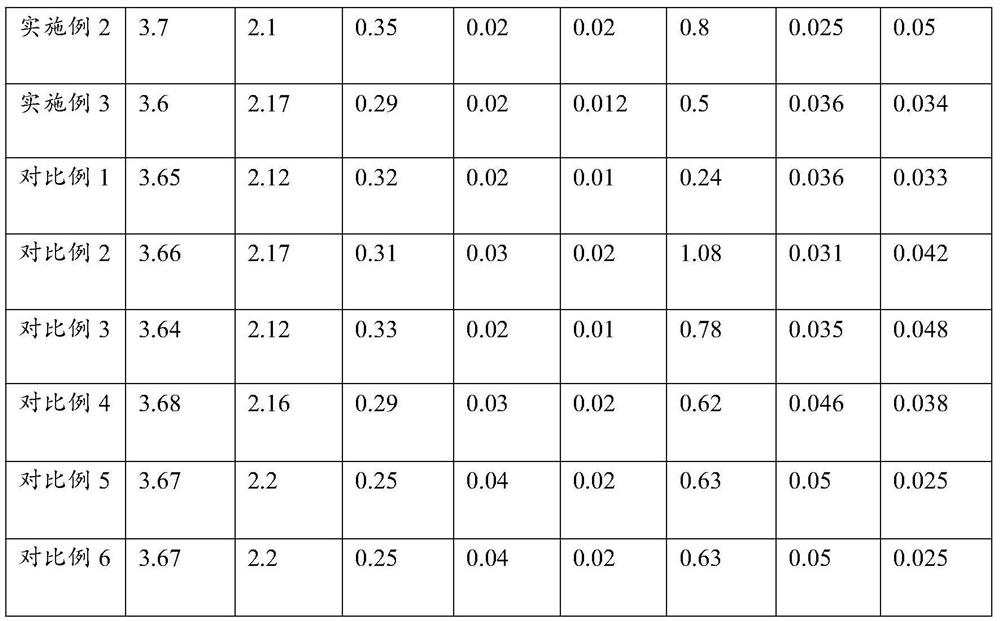

[0036] S1. Casting a ductile iron workpiece including the following weight percentage components: C: 3.6~3.7, Si: 2.1~2.2, Mn: 0.25~0.35, Cu: 0.5~0.8, S<0.02, P<0.04, Mg: 0.025~ 0.05, Ce: 0.025~0.05, the balance is Fe and unavoidable impurities;

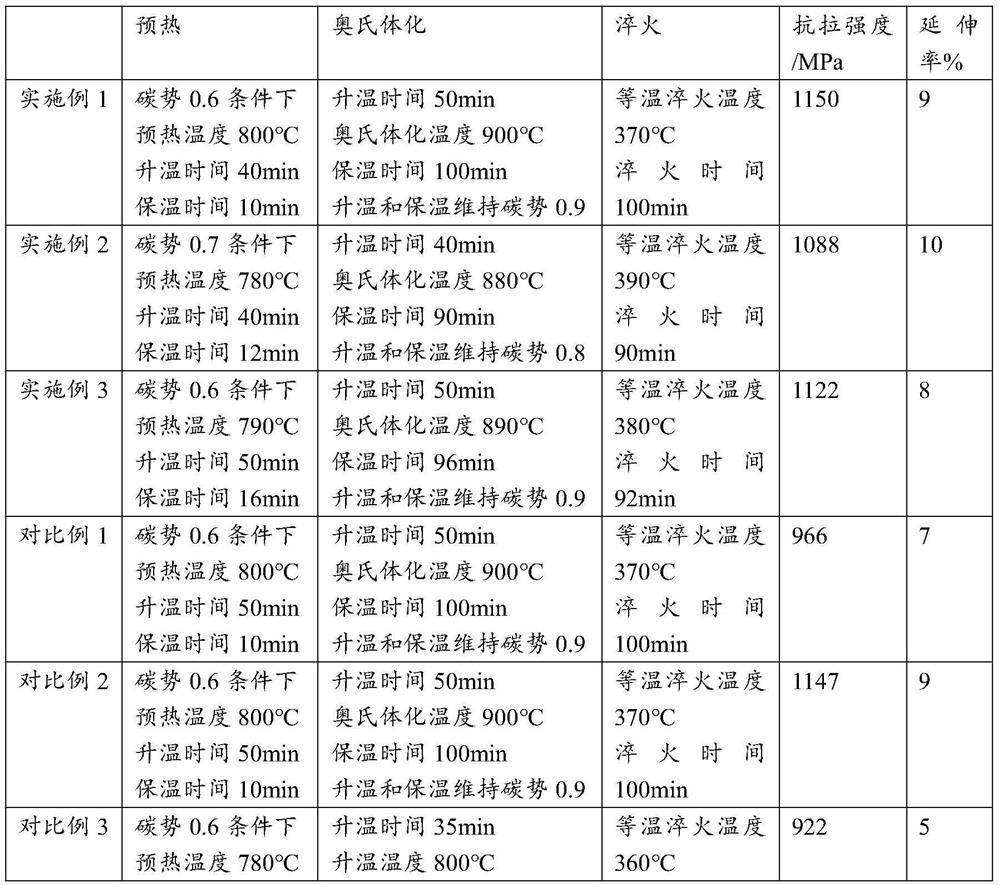

[0037] S2. Place the obtained nodular cast iron workpiece in a gas carburizing furnace, control the carbon potential of the furnace gas to 0.6-0.7, raise the furnace temperature to 760-780 °C, and keep it warm for 10-12 minutes; raise the carbon potential of the furnace gas to 0.8-0.7 0.9, then raise the furnace temperature to the austenitizing temperature and keep it warm;

[0038] S3. Immediately perform austempering treatment on the nodular cast iron workpiece to obtain an austempered nodular cast iron material.

[0039] Since the heat treatment in step S2 will reduce the graphite on t...

Embodiment 1

[0054] An austempering ductile iron material provided in this embodiment comprises the following components by weight percentage: C: 3.67, Si: 2.2, Mn: 0.25, Cu: 0.63, S: 0.02, P: 0.04, Mg: 0.025, Ce: 0.05, the balance being Fe and unavoidable impurities.

[0055] The present embodiment provides a method for preparing the above-mentioned austempering ductile iron material, comprising the following steps:

[0056] 1. Using conventional smelting methods, the required raw materials are melted into molten iron in an induction furnace; the molten iron is inoculated by pouring into the ladle, and the temperature is controlled at 1420°C for pouring, and after cooling, nodular cast iron workpieces are obtained;

[0057] 2. Place the ductile cast iron workpiece in a gas carburizing furnace, raise the temperature from room temperature to 800°C, and then keep it at 800°C for 10 minutes; the time from room temperature to 800°C is 40 minutes, and maintain the carbon potential of the furnac...

Embodiment 2

[0062] An austempering ductile iron material provided in this embodiment includes the following components by weight percentage: C: 3.7, Si: 2.1, Mn: 0.35, Cu: 0.8, S: 0.02, P: 0.02, Mg: 0.05, Ce: 0.025, the balance being Fe and unavoidable impurities.

[0063] The present embodiment provides a method for preparing the above-mentioned austempering ductile iron material, comprising the following steps:

[0064] 1. Using conventional smelting methods, the required raw materials are melted into molten iron in an induction furnace; the molten iron is inoculated by pouring into the ladle, controlled at a temperature of 1440°C for pouring, and after cooling, nodular cast iron workpieces are obtained;

[0065] 2. Place the ductile cast iron workpiece in a gas carburizing furnace, raise the temperature from room temperature to 780°C, and then keep it at 780°C for 12 minutes; the time from room temperature to 780°C is 60 minutes, and maintain the carbon potential of the furnace gas dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com