Color register control system and method for high-precision printing equipment

A printing equipment and control system technology, which is applied in the field of high-precision printing equipment color registration control system, can solve problems such as poor transparency, achieve the effects of avoiding errors, improving intelligence, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

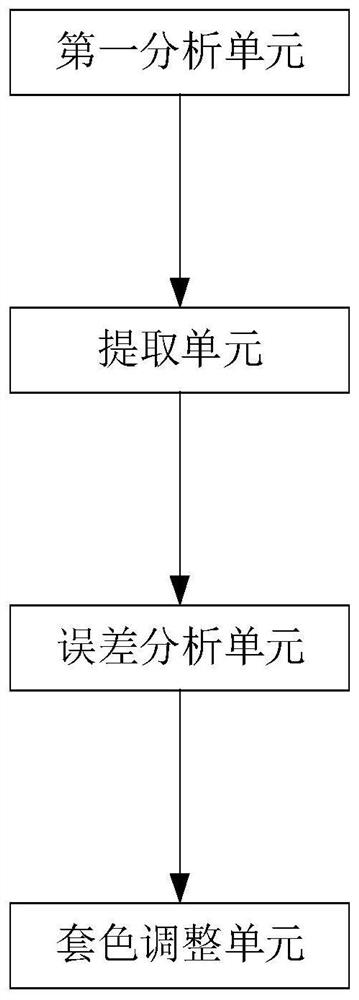

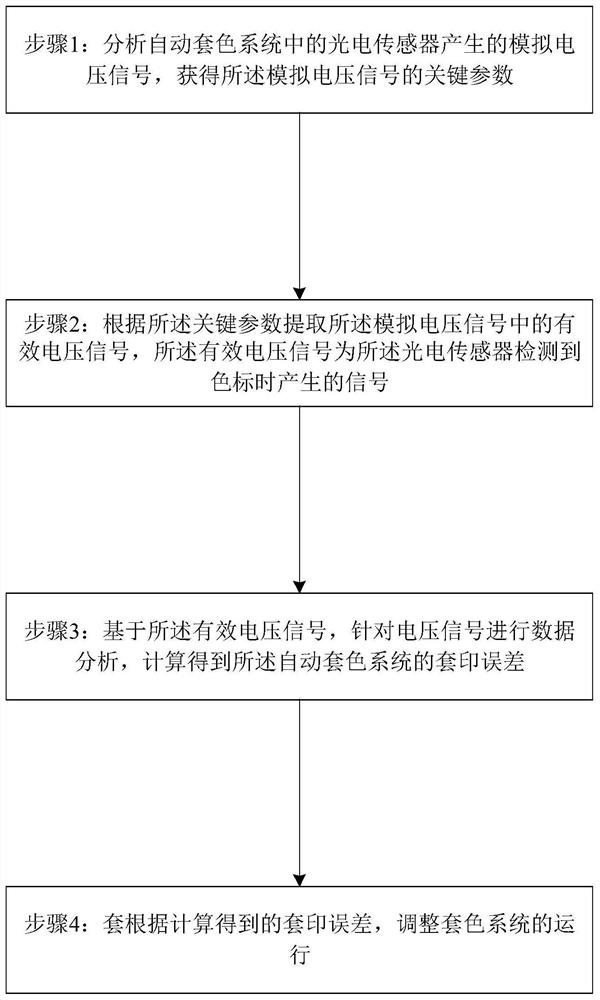

[0031] A high-precision printing equipment color registration control system, the system includes: a first analysis unit, used to analyze the analog voltage signal generated by the photoelectric sensor in the automatic color registration system, and obtain the key parameters of the analog voltage signal; the extraction unit uses Extracting an effective voltage signal in the analog voltage signal according to the key parameter, the effective voltage signal is a signal generated when the photoelectric sensor detects a color mark; an error analysis unit is configured to, based on the effective voltage signal, Perform data analysis on the voltage signal to calculate the overprint error of the automatic color registration system; the color registration adjustment unit is used to adjust the operation of the color registration system according to the calculated overprint error.

[0032] Specifically, the so-called special printing is to use special equipment and special technology to ...

Embodiment 2

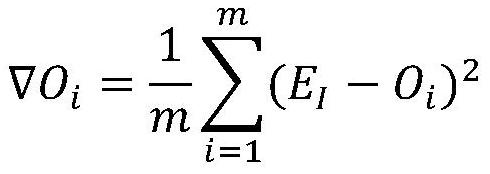

[0037] On the basis of the previous embodiment, the error analysis unit includes: a signal preprocessing unit, a signal specification unit, a signal standardization unit, an algorithm prediction unit, and a modeling analysis unit; the signal preprocessing removes signal information in sequence Unique attribute, processing missing value and outlier detection processing; the signal specification unit is used to perform specification processing on the signal after signal preprocessing, so that the signals after the protocol processing are irrelevant to each other, but keep the original information; The signal standardization unit scales the signal processed by the protocol to make it fall into the set interval; the algorithm prediction unit performs signal modeling according to the signal processed by the signal standardization unit; the modeling analysis unit uses The accuracy calculation is performed on the customer satisfaction signal generated by the calculation model and the ...

Embodiment 3

[0039] On the basis of the previous embodiment, the method for the signal standardization unit to perform signal standardization processing performs the following steps: perform signal standardization processing, and scale the signal to make it fall into the set interval; wherein, the following conversion is used Function, linearly transform the signal so that the result falls into the [0,1] interval, the conversion function is as follows: where x * is the result of signal normalization processing; x is the signal to be processed; min is the minimum value in the signal; max is the maximum value in the signal.

[0040] Specifically, before data analysis, we usually need to normalize the data first, and use the standardized data for data analysis. Data standardization is the indexation of statistical data. Data standardization processing mainly includes two aspects: data homogeneity processing and dimensionless processing. Data homogeneity processing mainly solves the proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com