Preparation method of functionally gradient diamond/aluminum composite material packaging shell

A technology of aluminum composite materials and packaging shells, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem of inability to prepare gradient composite materials in near-net shape, and achieve reduction in machining workload, Improved stability and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

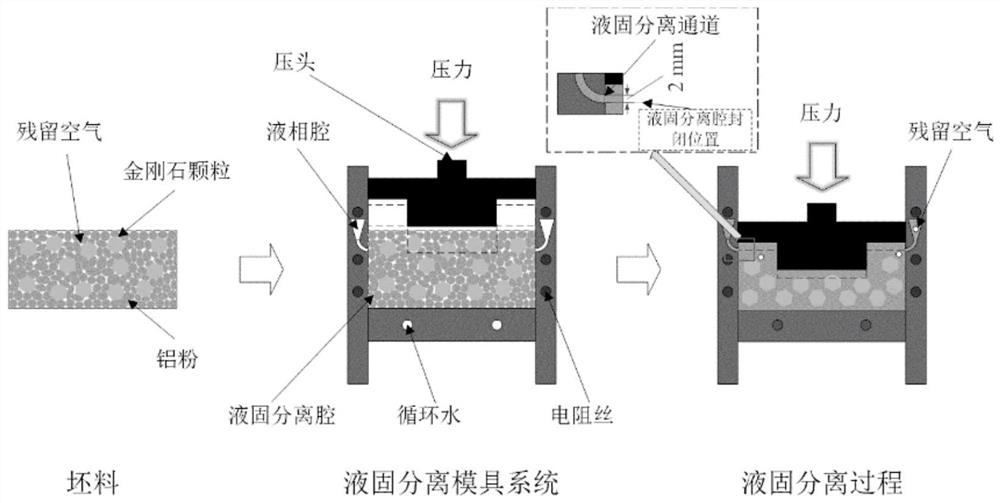

[0044] use figure 1 The liquid-solid separation system shown prepares a functionally graded diamond / aluminum composite package shell.

[0045] The diamond particles and aluminum powder are weighed according to the ratio (1:9-1:1), placed in a 3D mixer for mechanical mixing, and the mixing time is 1-48 hours.

[0046]Put the mixed powder into a cold-press mold, hold the pressure for 0.5-5 minutes under a pressure of 20-400 MPa, and make a block-shaped cold-press billet.

[0047] Put the cold-pressed billet into the liquid-solid separation mold system and keep it warm at 630-730°C for 10-60 minutes to make a liquid-solid mixed molten slurry in which diamond particles and liquid metal aluminum coexist.

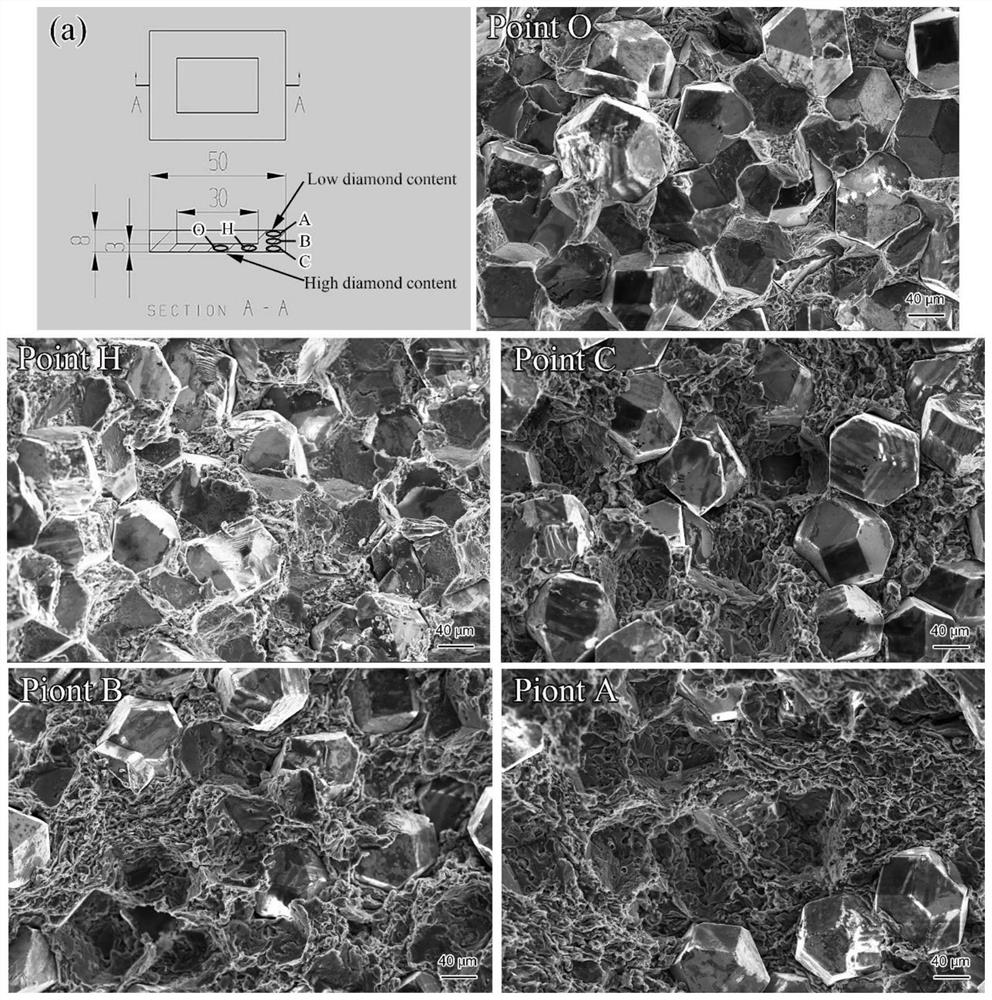

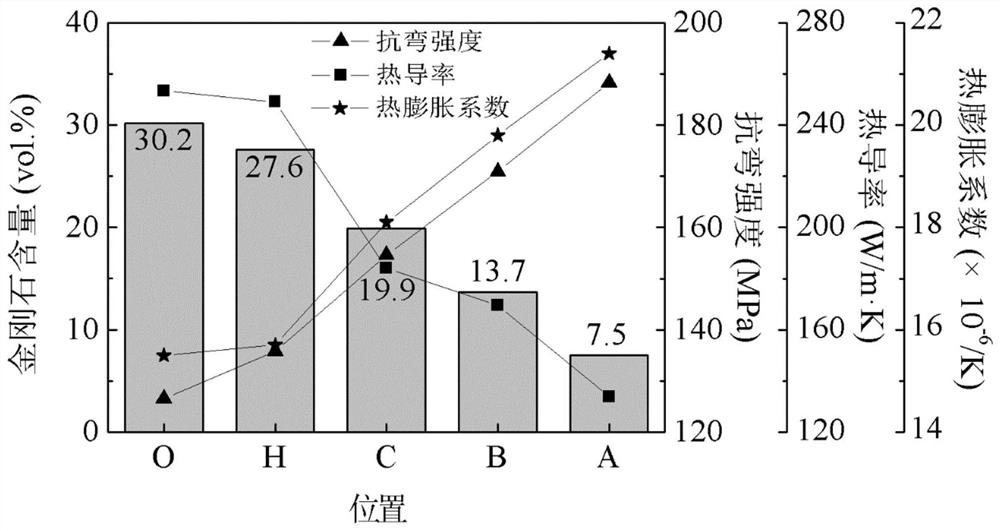

[0048] Under the action of the special-shaped indenter, the fluidity of the molten metal is ahead of that of the diamond particles, and it is reversely extruded from the bottom. The diamond content at the bottom of the shell is high, and the diamond content at the top of the wal...

specific Embodiment approach 2

[0052] This embodiment is different from the specific embodiment one in that:

[0053] Diamond particles and aluminum powder are mechanically mixed in a planetary ball mill.

[0054] The cold-pressed billet is heated under an inert gas protection atmosphere to prepare a liquid-solid mixed molten slurry.

[0055] The liquid-solid separation channel is a circular hole with a diameter of 0.5-5 mm.

[0056] The layer-by-layer solidification of the composite material is realized by forced cooling with an external cold iron.

specific Embodiment approach 3

[0058] This embodiment is different from the specific embodiment one in that:

[0059] The cold-pressed billet is placed in the pass with H 2 After being heated to a liquid-solid mixed molten state in an atmosphere-protected heating furnace, it is transferred to a special mold system with a liquid-solid separation channel.

[0060] The layer-by-layer solidification of the composite material is achieved by forced air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com