Flexible ceramic heavy anti-corrosion coating and preparation method thereof

A technology of flexible ceramics and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve the problems of inability to adjust the feeding speed according to needs, poor flexibility and impact resistance of the paint film, and coating grinding Reduce the effect of the coating and other problems, to achieve the effect of improving convenience, improving the anti-corrosion performance of the coating, and increasing the power utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

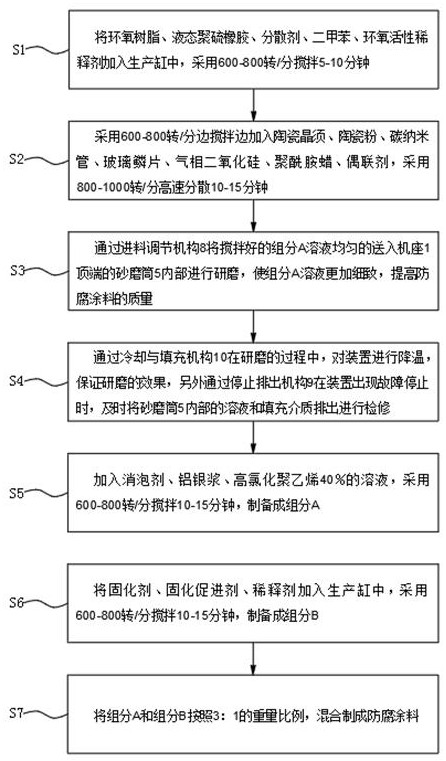

[0053] Embodiment 1: as Figure 1-2 Shown, a kind of preparation method of flexible ceramic heavy-duty anticorrosion coating comprises the steps:

[0054] S1. Add epoxy resin, liquid polysulfide rubber, dispersant, xylene, and epoxy reactive diluent to the production tank, and stir at 600-800 rpm for 5-10 minutes;

[0055] S2. Add ceramic whiskers, ceramic powder, carbon nanotubes, glass flakes, fumed silica, polyamide wax, coupling agent while stirring at 600-800 rpm, and disperse at 800-1000 rpm at high speed for 10 -15 minutes;

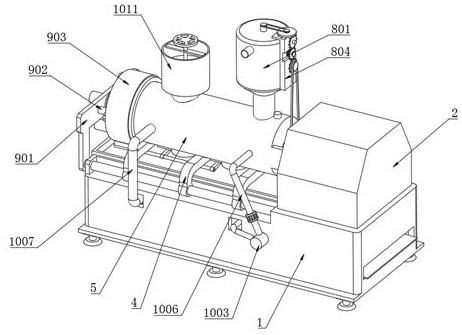

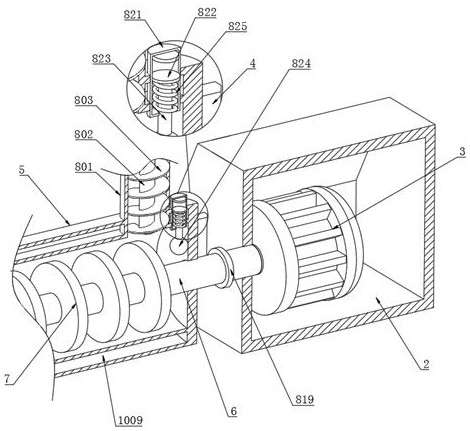

[0056] S3. Send the stirred component A solution evenly into the sand mill cylinder 5 at the top of the machine base 1 through the feed adjustment mechanism 8 for grinding, so that the component A solution is more detailed and the quality of the anti-corrosion coating is improved;

[0057] S4. During the grinding process, the cooling and filling mechanism 10 is used to cool down the device to ensure the grinding effect. In addition, when the devi...

Embodiment 2

[0091] Embodiment 2, a kind of flexible ceramic heavy-duty anticorrosion paint, comprises component A and component B of independent subpackage;

[0092] Component A includes by weight: 36 parts of epoxy resin, 6 parts of liquid polysulfide rubber, 4 parts of high-chlorinated polyethylene resin, 8 parts of ceramic whiskers, 9 parts of ceramic powder, 4 parts of carbon nanotubes, and 6 parts of glass flakes , 7 parts of aluminum silver paste, 1 part of dispersant, 1 part of polyamide wax powder, 1 part of fumed silica, 1 part of defoamer, 1 part of coupling agent, 8 parts of xylene, 7 parts of epoxy reactive diluent ;

[0093] Component B includes by weight: 40 parts of curing agent, 10 parts of curing accelerator, 25 parts of xylene, and 25 parts of n-butanol.

[0094] The weight ratio of the component A to the component B is 3:1

[0095] Described epoxy resin is E44;

[0096] The ceramic whiskers are silicon carbide;

[0097] The ceramic powder is alumina;

[0098] The d...

Embodiment 3

[0105] Embodiment 3, a kind of flexible ceramic heavy-duty anticorrosion paint, comprises component A and component B of independent packaging;

[0106] Component A includes by weight: 36 parts of epoxy resin, 5 parts of liquid polysulfide rubber, 5 parts of high-chlorinated polyethylene resin, 4 parts of ceramic whiskers, 13 parts of ceramic powder, 5 parts of carbon nanotubes, and 5 parts of glass flakes , 7 parts of aluminum silver paste, 1 part of dispersant, 1 part of polyamide wax powder, 1 part of fumed silica, 1 part of defoamer, 1 part of coupling agent, 8 parts of xylene, 80 parts of epoxy reactive diluent ;

[0107] Component B includes by weight: 40 parts of curing agent, 10 parts of curing accelerator, 25 parts of xylene, and 25 parts of n-butanol.

[0108] The weight ratio of the component A to the component B is 3:1

[0109] Described epoxy resin is E44;

[0110] The ceramic whiskers are silicon carbide;

[0111] The ceramic powder is alumina;

[0112] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com