Anti-blocking master batch for thermoplastic polyurethane film and preparation method of anti-blocking master batch

A thermoplastic polyurethane and anti-blocking technology, applied in the field of TPU materials, can solve the problems of affecting film transparency, large amount of addition, difficulty in dispersion, etc., and achieve the effect of maintaining no precipitation and slippery feeling, reducing friction coefficient, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

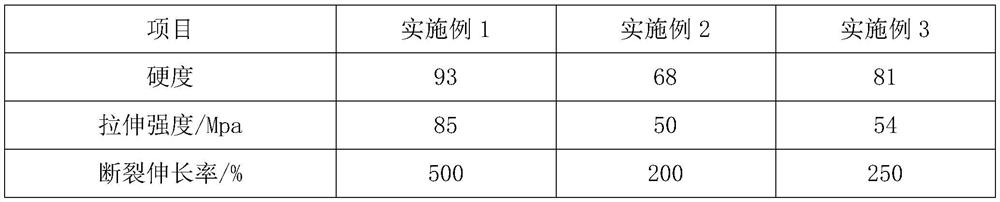

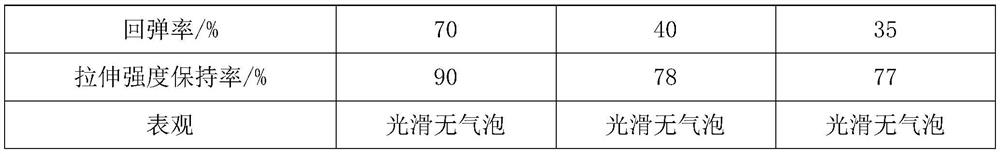

Examples

Embodiment 1

[0024] This project aims to research and develop an anti-blocking masterbatch for thermoplastic polyurethane film, which contains the following components: TPU: 95%, anti-blocking agent: 4%, antistatic agent: 1%; among them, anti-blocking agent mainly For the compounding of amide waxes and nano-scale silica, the amide waxes used include but not limited to oleic acid amide, erucic acid amide, behenic acid amide, stearic acid amide and ethylene bisoleic acid amide, etc. or montan wax .

[0025] The anti-blocking masterbatch is a special anti-blocking masterbatch for aliphatic TPU. After use, it quickly disperses on the surface of the film to form a lubricating molecular layer, which reduces the friction coefficient of the film and has an excellent anti-blocking effect.

[0026] The anti-adhesion masterbatch is a polymer permanent anti-adhesion masterbatch that is insoluble in water. Its appearance is white powder or granular anti-adhesion masterbatch, and its thermal decomposit...

Embodiment 2

[0034] An anti-blocking master batch for thermoplastic polyurethane film, the master batch comprises the following components: TPU: 94%, anti-blocking agent: 4%, antistatic agent: 2%.

[0035] A kind of preparation method of anti-blocking masterbatch for thermoplastic polyurethane film, comprises the steps:

[0036] Step 1, weighing each component according to the weight ratio; TPU: 94%, anti-blocking agent: 4%, antistatic agent: 2%;

[0037] Step 2: Mix TPU particles and antistatic agent into a high-speed mixer, stir at a high speed of 3000-6000r / min at a temperature of 100-120°C for 20-50min, and then discharge the material into a low-speed cooling mixer to Stir at a speed of 50-120r / min, and wait until the material is cooled to 40°C-50°C to obtain a premix;

[0038] Step 3: Add an anti-blocking agent to the premix in Step 2, continue to stir for 10-30 minutes, and discharge after mixing evenly;

[0039] Step 4, put the material prepared in step 3 into a twin-screw extrude...

Embodiment 3

[0041] An anti-blocking master batch for thermoplastic polyurethane film, the master batch comprises the following components: TPU: 93%, anti-blocking agent: 5%, antistatic agent: 2%.

[0042] A kind of preparation method of anti-blocking masterbatch for thermoplastic polyurethane film, comprises the steps:

[0043] Step 1, weighing each component according to the weight ratio; TPU: 4%, anti-blocking agent: 4%, antistatic agent: 2%;

[0044]Step 2: Mix TPU particles and antistatic agent into a high-speed mixer, stir at a high speed of 3000-6000r / min at a temperature of 100-120°C for 20-50min, and then discharge the material into a low-speed cooling mixer to Stir at a speed of 50-120r / min, and wait until the material is cooled to 40°C-50°C to obtain a premix;

[0045] Step 3: Add anti-blocking agent to the premix in Step 2, continue to stir for 10-30 minutes, and discharge the mixture after mixing evenly;

[0046] Step 4, put the material prepared in step 3 into a twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com