A medium-low frequency sound-absorbing structural part and its preparation method

A structural part and sound-absorbing technology, applied in 3D object support structures, manufacturing tools, sound-generating devices, etc., can solve problems such as restricting application effects, and achieve the effects of facilitating large-scale production and application, short production cycle, and improving multiple reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

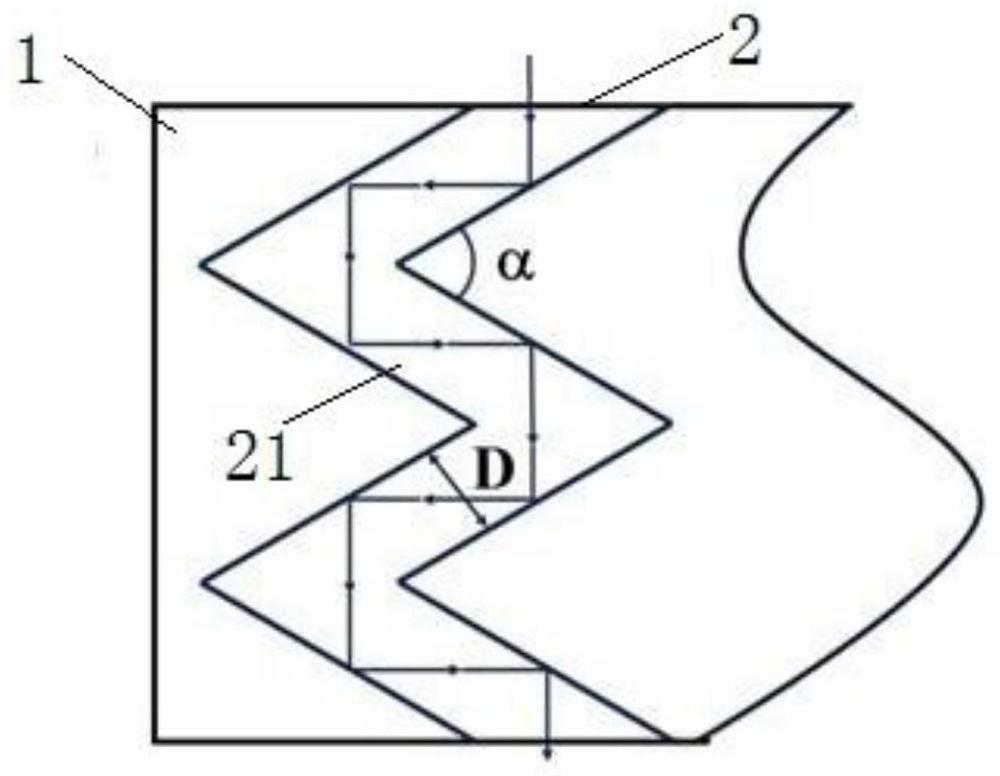

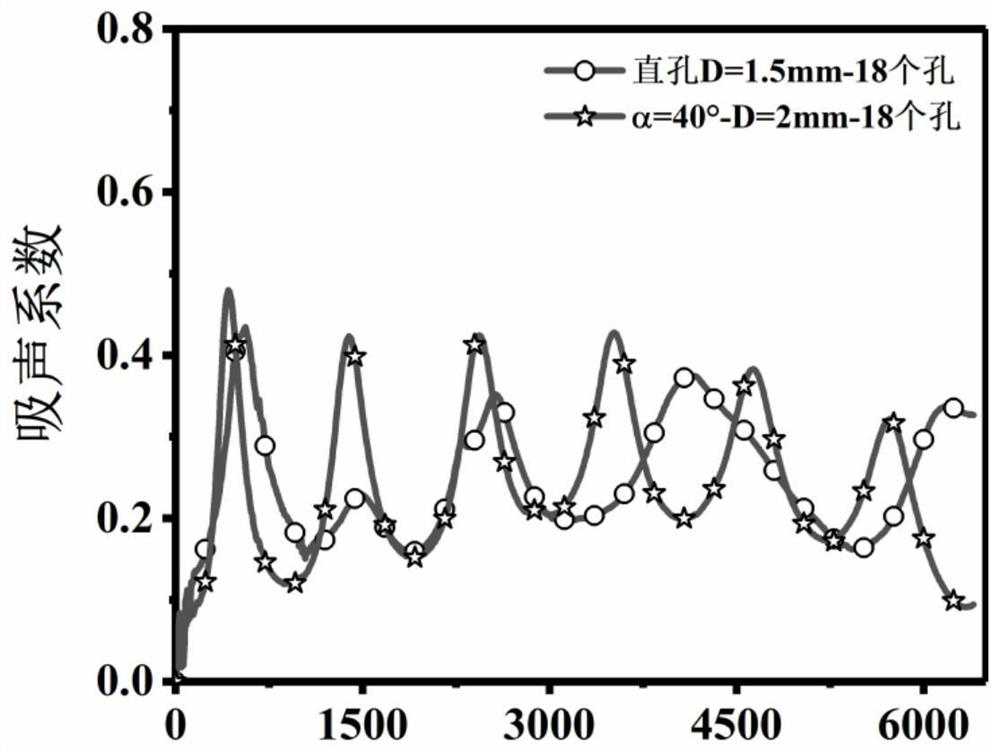

[0032] 1) Use 3ds max three-dimensional modeling software to build a cylinder with a diameter of 29mm and a height of 80mm, and then design the following polyline holes inside the cylinder, the diameter of which is 1.5mm, the bending angle of the polyline hole is 40°, and the polyline The number of holes is 18, and the perforation rate is 14.08%.

[0033] 2) Polylactic acid (PLA) filament printing consumables with a diameter of 1.75mm were manufactured by extrusion molding equipment; PLA powder and toughening agent were prepared and mixed uniformly in a mass ratio of 9:1; the above mixed raw materials were at 30 ℃ After drying for 2 hours, pour it into the feeding port of the extrusion equipment, heat the raw material to a molten state, and push the molten raw material to extrude the wire from the extrusion head through the rotation of the screw. The rotation speed was 45 r / min, and the diameter of the extrusion head was 1.75 mm.

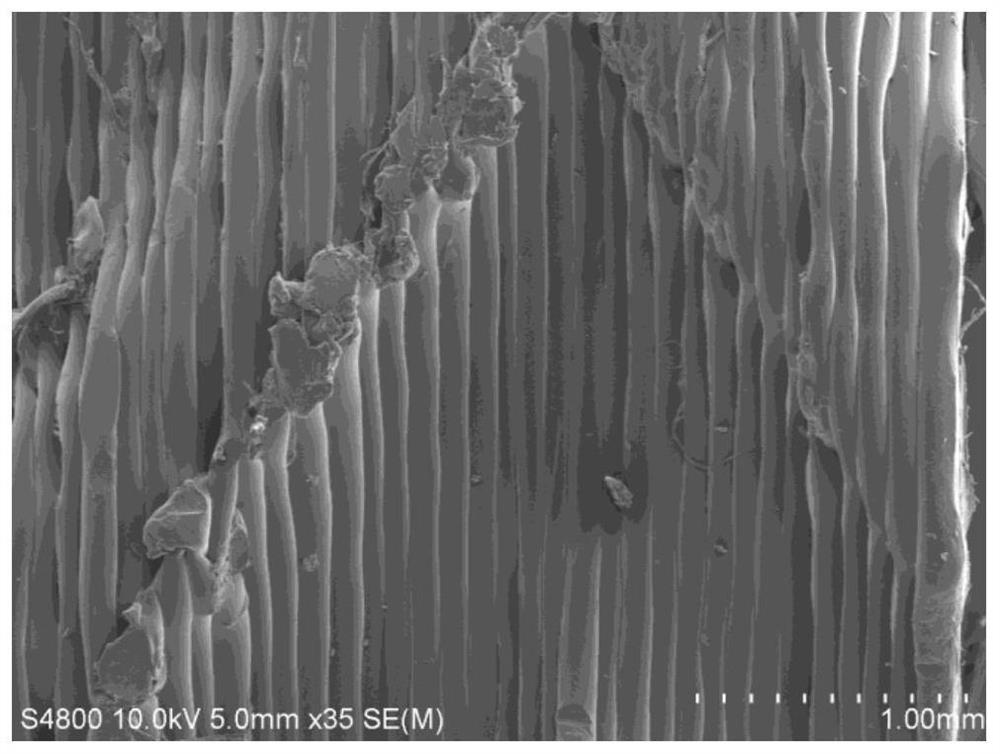

[0034] 3) Use a 3D printer to process and sh...

Embodiment 2

[0043] 1) Use 3ds max three-dimensional modeling software to build a cylinder with a diameter of 29mm and a height of 80mm, and then design the following polyline hole inside the cylinder, the hole diameter of which is 1.5mm, the bending angle of the polyline hole is 50°, and the polyline The number of holes is 18, and the perforation rate is 11.39%.

[0044] 2) Polypropylene (PP) filament printing consumables with a diameter of 1.75mm are manufactured by extrusion molding equipment; PP powder and toughening agent are configured and mixed uniformly according to the mass ratio of 9.6:0.4; the above mixed raw materials are at 40 ℃ After drying for 3 hours, pour it into the feed port of the extrusion equipment, heat the raw material to a molten state, and push the molten raw material to extrude the wire from the extrusion head through the rotation of the screw. The rotation speed was 65 r / min, and the diameter of the extrusion head was 1.75 mm.

[0045] 3) Use 3D printer to proc...

Embodiment 3

[0049] 1) Use 3ds max three-dimensional modeling software to build a cylinder with a diameter of 29mm and a height of 80mm, and then design the following polyline holes inside the cylinder, where the hole diameter is 1.5mm, the bending angle of the polyline hole is 60°, and the polyline The number of holes is 18, and the perforation rate is 9.63%.

[0050] 2) Polycarbonate (PC) filamentary printing consumables with a diameter of 1.75mm are manufactured by extrusion molding equipment; PC powder and toughening agent are configured and mixed uniformly according to the mass ratio of 9.2:0.8; The above mixed raw materials are at 50 After drying at ℃ for 3 hours, pour it into the feed port of the extrusion equipment, heat the raw material to a molten state, and push the molten raw material to extrude the wire from the extrusion head through the rotation of the screw. The rotation speed is 50r / min, and the diameter of the extrusion head is 1.75mm.

[0051] 3) Use a 3D printer to pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com