Preparation method of magnesium oxide secondary emitter

A technology of magnesium oxide and emitters, which is applied in the manufacture of secondary emitter electrodes, the manufacture of light-emitting cathodes, sputtering coating, etc., can solve the problems of excessive gain attenuation, low gain of electron multipliers, and weak bombardment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

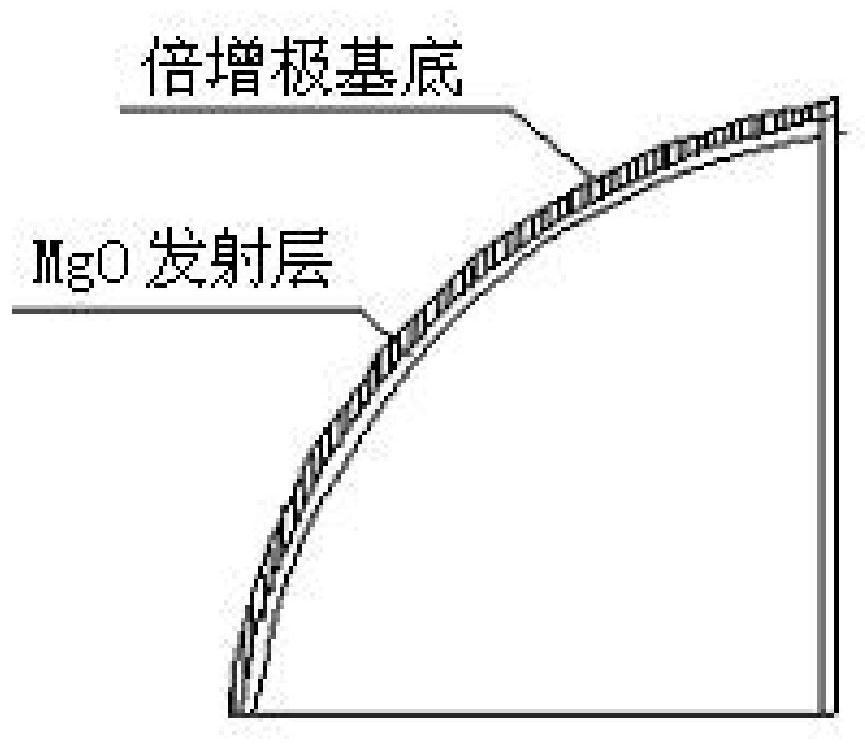

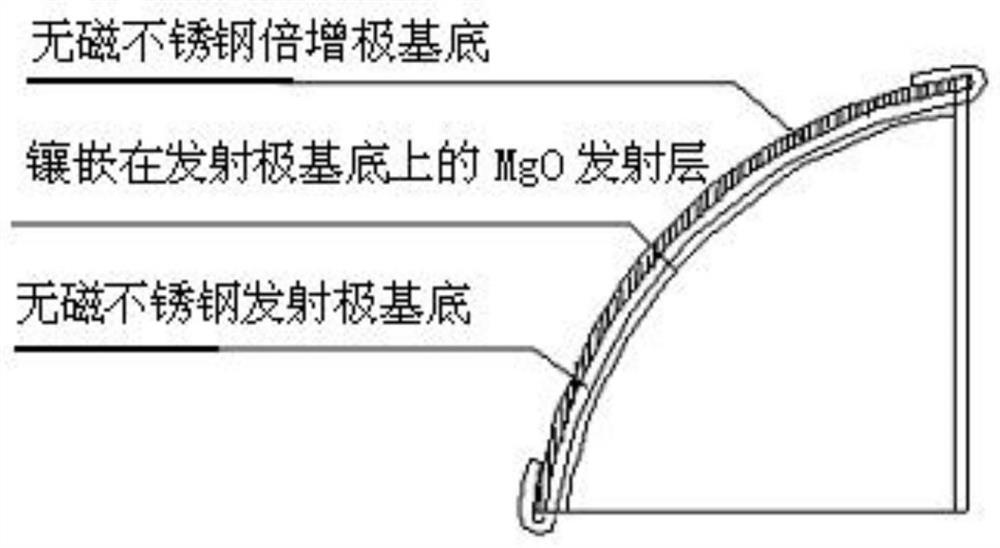

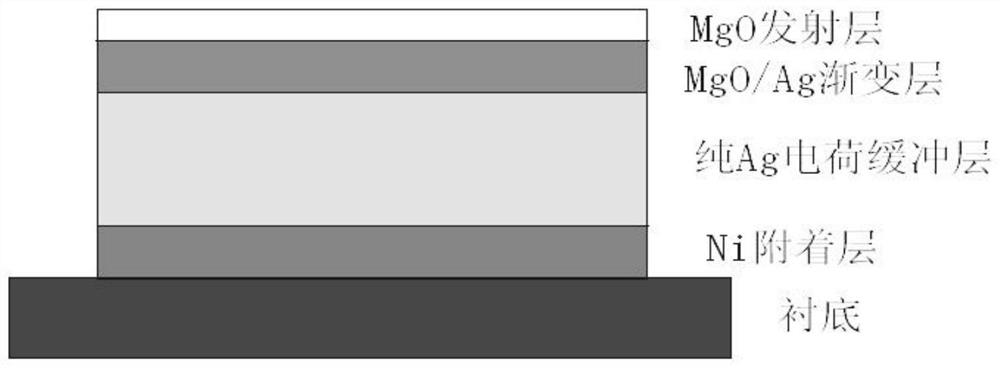

Image

Examples

Embodiment 1

[0097] A preparation method of a magnesium oxide secondary emitter, comprising the steps of:

[0098] (1) Preparation of composite transition layer

[0099] (1.1) Place the processed non-magnetic stainless steel emitter substrate in the magnetron sputtering table, place the side that needs to be coated upwards, and the parts must not block each other;

[0100] (1.2) When the vacuum degree of the cavity reaches better than 5.0×10 -4 Start the heating system at Pa, heat the base substrate temperature of the emitter to 400°C and keep it warm for 1 hour, and degas the non-magnetic stainless steel multiplier pole pieces;

[0101] (1.3) After baking and degassing, when the temperature drops below 150°C, open the valve of the gas mass flow meter and adjust the flow of argon to keep the vacuum at 2.0×10 -2In the Pa state, turn on the auxiliary deposition high-voltage power supply, adjust the voltage to 200V, turn on the magnetron bombardment high-voltage power supply and film thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com