Preparation process of a low-cost hydraulic pump material suitable for copper clad process

A preparation process and technology for hydraulic pumps, applied in the field of pump materials, can solve problems such as low matrix strength, and achieve the effects of improving mechanical properties, good fatigue resistance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

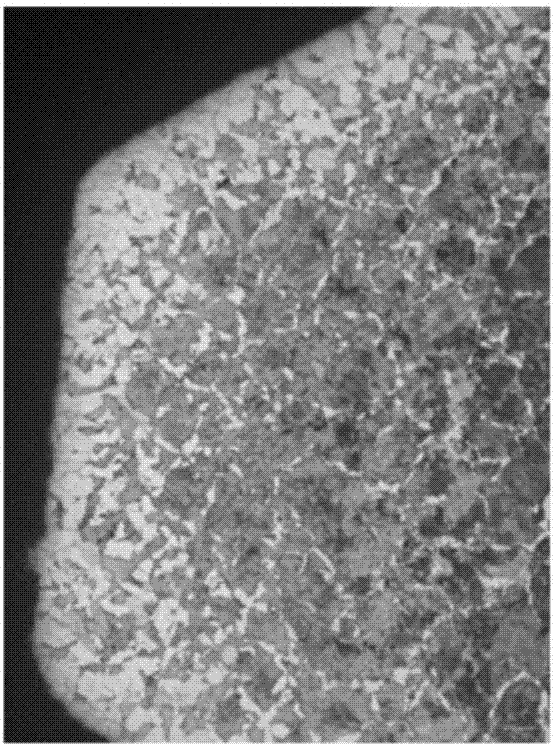

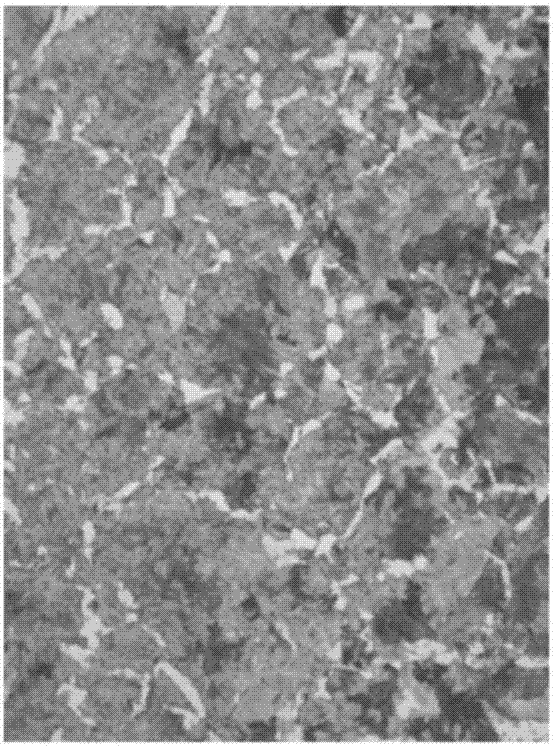

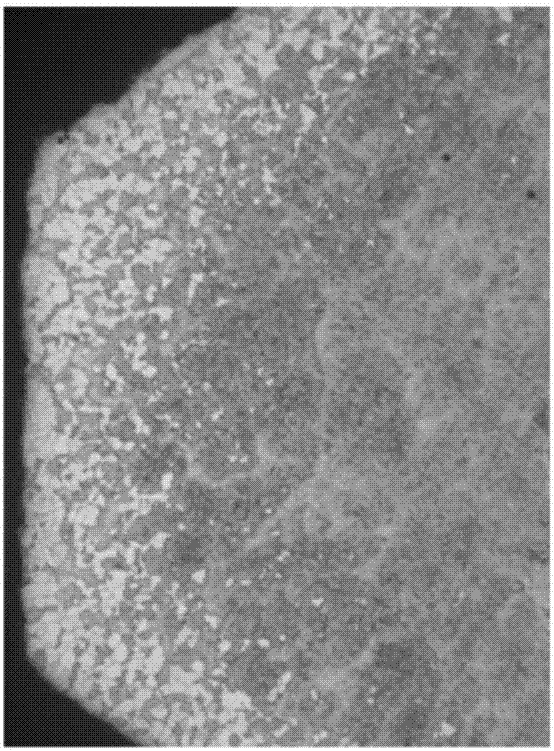

Image

Examples

Embodiment 1

[0016] It is smelted in a 500 kg induction furnace, molded into an ingot with a diameter of 400 mm, and forged into a bar with a diameter of 125 mm by a 750 electro-hydraulic hammer. The material composition is C0.38%, Si1.2wt%, Mn0.70wt%, Cr0 .6wt%, S0.015wt%, P0.015wt%, B0.0015wt%, the balance is Fe.

[0017] The pump body blank is prepared by mechanical processing, using 1050°C ± 50°C copper clad process, 600°C ± 50°C nitriding treatment and induction treatment. The results are as follows: Copper clad at 1050°C, the tensile strength of the pump body sampling material is 915MPa; the nitriding hardness at 550°C is 652HV / 5Kg, and the depth is greater than 0.3mm; the hardness of the induction-treated teeth is greater than 356HV, the depth is greater than 0.5mm, and the hardness of the matrix is 346HV / 0.3Kg , to meet the requirements of the hydraulic pump on the mechanical properties of the material, the depth of the nitrided layer and the hardenability.

Embodiment 2

[0019] It is smelted in a 500 kg induction furnace, molded into an ingot with a diameter of 400 mm, and forged into a bar with a diameter of 125 mm by a 750 electro-hydraulic hammer. The material composition is C0.44wt%, Si1.6wt%, Mn1.00wt%, Cr1 .1wt%, S0.010wt%, P0.016wt%, B0.0030wt%, the balance is Fe.

[0020] The pump body blank is prepared by mechanical processing, using 1050°C ± 50°C copper clad process, 600°C ± 50°C nitriding treatment and induction treatment. The results are as follows: Copper clad at 1050°C, the tensile strength of the pump body sampling material is 923MPa, the nitriding hardness at 550°C is 665HV / 5Kg, and the depth is greater than 0.3mm; the hardness of the induction-treated teeth is greater than 534HV, the depth is greater than 0.5mm, and the hardness of the matrix is 346HV / 0.3Kg , to meet the requirements of the hydraulic pump on the mechanical properties of the material, the depth of the nitrided layer and the hardenability.

Embodiment 3

[0022] It is smelted in a 50-ton electric arc furnace, then refined in an LF furnace, vacuum degassed (VD), degassed and cast into an ingot, which is forged into a rod for the pump body. The material composition is C0.40wt%, Si1. 4wt%, Mn0.90wt%, Cr0.9wt%, S0.014wt%, P0.020wt%, B0.00165wt%, the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com