Mildew-proof, flame-retardant and wear-resistant integrated odorless plant fiber reinforced thermoplastic polymer composite material as well as preparation and application thereof

A thermoplastic polymer and enhanced thermoplastic technology, used in the field of automotive interior materials, can solve the problem of not meeting the requirements of the OEM for the use of polymer-based materials, the incompatible interface between plant fibers and thermoplastic polymers, and affecting the macroscopic physical and mechanical properties. and other problems to achieve the effect of improving interfacial compatibility, reducing moisture adsorption sites, and enhancing interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

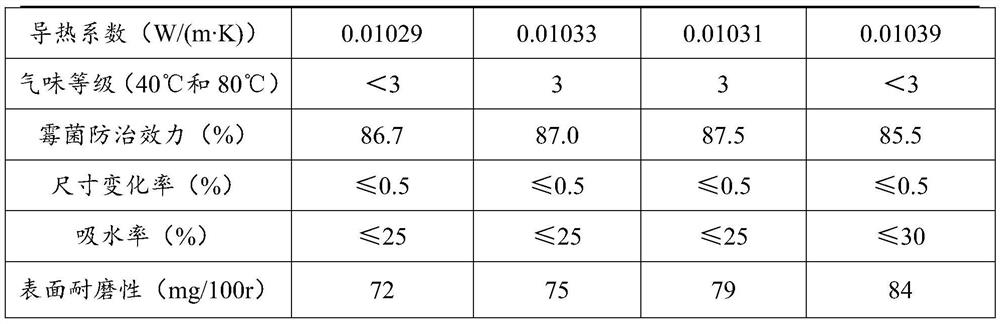

Examples

preparation example Construction

[0024] The invention provides a method for preparing a mildew-proof, flame-retardant and wear-resistant integrated plant fiber reinforced thermoplastic polymer composite material, comprising the following steps:

[0025] modifying the interface of the plant fiber to obtain the modified plant fiber;

[0026] Blending granulation or self-assembly of thermoplastic polymers and additives to obtain modified thermoplastic polymers;

[0027] mixing the modified plant fiber and the modified thermoplastic polymer, and spinning to obtain a composite fiber;

[0028] The composite fibers are sequentially subjected to dedusting, carding and laying, needle felting, hot pressing and edge sealing treatment to obtain a plant fiber reinforced thermoplastic polymer composite material;

[0029] The auxiliary agent includes odor absorbing agent, antifungal agent, flame retardant, anti-wear agent and interface compatibilizer.

[0030] In the present invention, unless otherwise specified, the requ...

Embodiment 1

[0060] Add 40g of KH550 to 1960g of absolute ethanol, stir for 5min, then add 100g of bamboo fiber, continue to stir for 25min, seal it with plastic wrap and let it stand for 30min, wash and dry the obtained product with deionized water, then put it in an oven at 150°C for Heat treatment, obtains modified bamboo fiber;

[0061] Polypropylene and additives (porous calcium silicate 5wt%, cassia bark oil 3wt%+nano-titanium dioxide 1.5wt%, basic magnesium sulfate whisker synergistic microcapsule red phosphorus 15wt%, hollow glass microspheres 10wt%, maleic anhydride branched polypropylene 2.5wt%) placed in a high mixer and blended for 30min, then placed in a granulator for granulation, and the resulting material was granulated in a granulator, and the temperatures of the first zone to the fourth zone of the granulator were sequentially Modified polypropylene is obtained at 150±10°C, 170±10°C, 190±10°C and 160±10°C;

[0062]The modified bamboo fiber and the modified polypropylene ...

Embodiment 2

[0064] According to the raw material ratio and steps of Example 1, KH550 is used to modify the interface of bamboo fiber and hemp fiber respectively, and the resulting 35wt% modified bamboo fiber and 15wt% modified hemp fiber are put into an oven at 170°C for heat treatment. Obtain modified composite fiber;

[0065] Polypropylene and additives (5wt% of nano-montmorillonite, 3wt% of chitosan+1.5wt% of nano-titanium dioxide, 15wt% of expandable graphite, 10wt% of floating beads, 2.5wt% of maleic anhydride grafted polyPOE) Mix in the high-mixer for 30 minutes, then put it in the granulator for granulation, and cut the obtained material into pellets in the granulator. ℃, 190±10℃ and 160±10℃ to obtain modified polypropylene;

[0066] The modified composite fiber and modified polypropylene are mixed and spun according to the ratio of 50wt%:50wt%, and the resulting composite fiber is successively dedusted, mechanically carded, laid, and needle-punched into felt, and then hot-pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com