Butyronitrile raw material nano calcium filling material technology

A nano-calcium and filler technology, which is applied in the field of chemical material preparation, can solve problems such as poor impact resistance of nitrile rubber, poor compatibility between particles and the matrix, and affect material safety, so as to increase the viscosity of the system and improve fluidity and plasticity, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

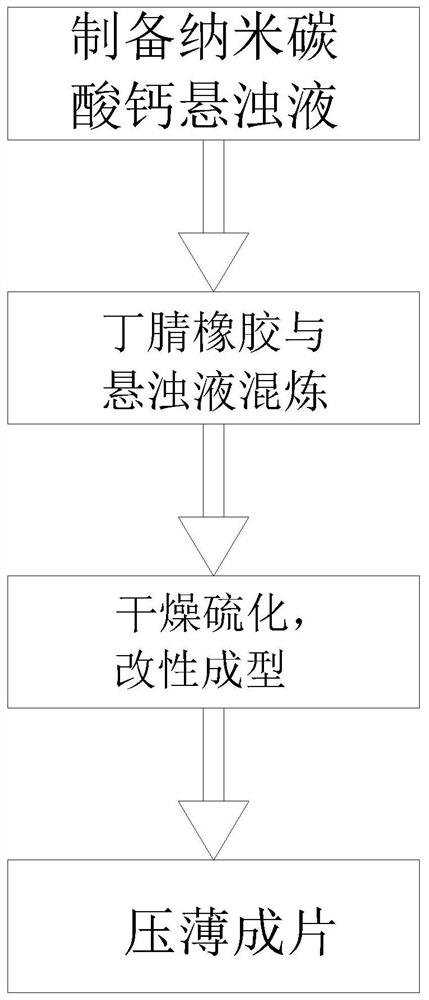

[0033] Such as figure 1 Shown, the present invention provides a kind of nitrile raw material nano-calcium filler technology, this nitrile raw material nano-calcium filler technology, comprises the following steps:

[0034] Step 1, preparing nano-calcium carbonate suspension;

[0035] Step 2, mixing of nitrile rubber and suspension;

[0036] Step 3, dry vulcanization, modification molding;

[0037] Step 4, compress into thin slices.

[0038] In this example, through the mixing of nano-calcium carbonate suspension and nitrile rubber, a more stable and simple preparation method is provided for the strength and toughness of nitrile rubber, and the preparation of modified molding by dry vulcanization The process can accelerate the speed of material preparation, ensure the environmental protection of material production, and further improve the efficiency of material preparation.

[0039] Such as figure 1 As shown, in the present embodiment, preferably, step 1 also includes: na...

Embodiment 2

[0041] Such as figure 1 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, step 2 also includes: nitrile rubber adopts rubber latex to make, and the composition of rubber latex is 40% natural latex An organic compound formed by combining 35 percent nitrile latex and 25 percent polybutadiene latex, by utilizing the similar material properties of natural latex, nitrile latex and polybutadiene latex , so that its mixing rate and compatibility are higher, and the proportion of natural latex is matched to ensure the environmental protection performance of rubber latex. The mixing of nitrile rubber and suspension needs to add gelling agent. The gelling agent is gelatin and casein acid One or two of sodium, gum arabic, agar, xanthan gum, and gellan gum, and the addition of various natural organic gelling agents can not only increase the viscosity of the material mixture, but also ensure that it is in an emulsified state , and ...

Embodiment 3

[0043] Such asfigure 1 As shown, on the basis of Example 1 and Example 2, the present invention provides a technical solution: preferably, step 3 also includes: a vulcanization activator needs to be added in the dry vulcanization process, and the composition of the vulcanization activator is a vulcanization accelerator M, and the proportion of the vulcanization accelerator M is 0.5% of the total amount of the nitrile rubber and the suspension. Through the action of the vulcanization accelerator M, the vulcanization speed of the preparation process is accelerated, and the strength and stability of the material are improved. At the same time, the vulcanization accelerator M itself has both anti-aging and peptizing effects, which can add subsidiary attributes to the material and improve the product performance of the material. During the drying and vulcanization process, it is necessary to add activated carbon with a ratio three times that of the vulcanization accelerator M, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com