Flame-retardant biodegradable polyester and preparation method thereof

A biodegradable polyester and flame-retardant technology, applied in the field of flame-retardant polyester, can solve the problems of difficulty in meeting practical application requirements, lower elongation at break, and high demand for phosphorus content, so as to reduce usage and increase thermal stability , Improve the effect of carbonization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

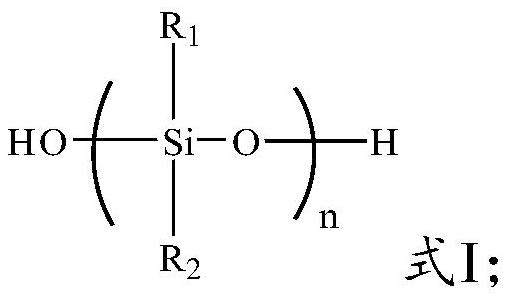

[0033] The invention provides a preparation method of flame-retardant biodegradable polyester, comprising:

[0034] Esterifying dibasic acid, dibasic alcohol, silanol flame retardant monomer and catalyst to obtain the first reaction product;

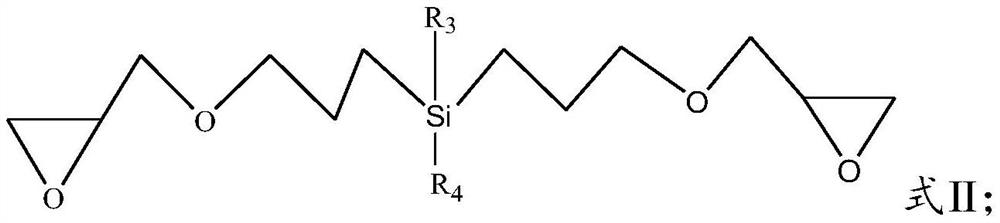

[0035] performing polycondensation reaction of the first reaction product and diepoxysilane to obtain a second reaction product;

[0036] The second reaction product, the phosphorus-containing chain extender and the nitrogen-containing auxiliary chain extender are subjected to a chain extension reaction; and a flame-retardant biodegradable polyester is obtained.

[0037] In the present invention, the dibasic acid is preferably selected from one or more of aliphatic dibasic acids and aromatic dibasic acids; the aliphatic dibasic acid is preferably selected from oxalic acid, malonic acid, One of succinic acid, glutaric acid, adipic acid, suberic acid, sebacic acid and malic acid; the aromatic dibasic acid is preferably selected from terep...

Embodiment 1

[0075] Add 3.984kg of terephthalic acid, 3.796kg of adipic acid, 379.0g of organosilicon diol (diphenylsilanediol), 8.1kg of 1,4-butanediol, and 31.44g of tetrabutyl titanate to the reaction In the kettle, stir and heat up to 230°C for 1.5h, add 95.50g of diepoxysilane (1,1,3,3-tetramethyl-1,3-bis-[2-[7-oxidized bicyclo[4.1. 0] hept-3-yl] ethyl] disiloxane), then heated to 250 ° C, vacuum 100Pa polycondensation reaction 2h, added 314.4g phenyl phosphoryl dichloride and 125.76g cyclic carbodiimide to the system (TCC-NP of Teijin Group), reacted for 15 minutes to obtain flame-retardant biodegradable polyester.

Embodiment 2

[0077] Add 4.15kg of terephthalic acid, 5.05kg of sebacic acid, 4.95kg of 1,4-butanediol, 370.0g of organosilicon diol (diisopropylsilanediol), and 11.9g of tetrabutyl titanate in sequence In the reaction kettle, stir and heat up to 230°C for 2 hours, add 249.0g of diepoxysilane (1,1,3,3-tetramethyl-1,3-bis-[2-[7-oxidized bicyclo[4.1. 0] hept-3-yl] ethyl] disiloxane), then heated to 250 ° C, vacuum 100Pa polycondensation reaction 3h, added 261.8g phenylphosphoryl dichloride and 59.5g cyclic carbodiimide to the system (TCC-FP20M of Teijin Group), reacted for 20 minutes to obtain flame-retardant biodegradable polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com