Polymer-steel composite material and preparation method thereof

A technology of composite materials and polymers, applied in the coating process of metal materials, etc., can solve the problems of low bonding strength between steel and polymer interfaces, and difficulty in meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

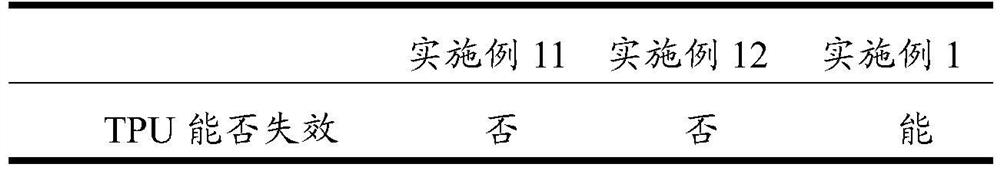

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of polymer-steel composite material, comprises the following steps:

[0026] (1) Carry out first annealing to steel, obtain annealed state steel;

[0027] (2) blasting the annealed steel obtained in the step (1) to obtain the blasted steel;

[0028] (3) performing surface silanization treatment after heating the blasted steel obtained in the step (2) to obtain surface modified steel;

[0029] (4) performing polymer injection molding on the surface-modified steel obtained in the step (3) to obtain a composite body;

[0030] (5) Performing the second annealing on the composite body obtained in the step (4) to obtain a polymer-steel composite material.

[0031] In the present invention, the steel is preferably mold steel or stainless steel; the mold steel is preferably mold steel H13, mold steel 718 or stainless steel S136. The present invention has no special limitation on the source of the steel, which can be prepare...

Embodiment 1

[0071] (1) First, the commercially available die steel H13 is made into a steel plate of 45*20*2mm (length*width*thickness), and then the steel plate is rapidly heated to 800°C at 20°C / min for the first annealing treatment for 1h. Then cool down to room temperature at 5°C / min, then use 180-mesh metallographic sandpaper for mechanical polishing, and finally put the steel plate into a beaker, add acetone for ultrasonic cleaning for 5 minutes, and then use alcohol for ultrasonic cleaning for 5 minutes to obtain an annealed steel plate;

[0072] (2) Put the annealed steel plate obtained in the step (1) into a sandblasting machine, fix it at a position 4cm away from the nozzle, use 150 mesh brown corundum to carry out sandblasting for 60s, the air pressure is 0.4MPa, and the sandblasting angle is 90°, then blow off the floating sand on the surface of the sample with an air nozzle, put it into a beaker, add alcohol and ultrasonically clean it for 5 minutes, and get a sandblasted stee...

Embodiment 2

[0081] On the basis of Example 1, the temperature of the second annealing treatment was replaced with 120° C., and other steps remained unchanged, to obtain a polymer-steel composite material.

[0082] According to the ASTM D1002 standard, the polymer-steel composite material prepared in Example 2 is used to carry out the tensile-shear experiment test with a tensile testing machine, and the tensile rate is 2mm / min to obtain the tensile shear strength of the polymer-steel composite material It is 16.59MPa. At this time, the polymer is broken, but the interface between the polymer and the steel is not damaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com