Welding method of tantalum target material assembly

A welding method and tantalum target technology, applied in welding equipment, cold-pressed connection, connecting components, etc., can solve the problems of low welding bonding strength, poor coating performance of target components, and short service life, etc., and improve the welding bonding strength. , The effect of uniform thickness and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

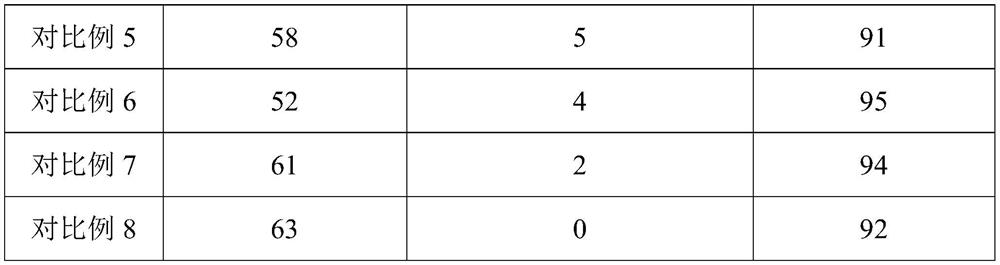

Examples

Embodiment 1

[0042] This embodiment provides a welding method for a tantalum target assembly, and the welding method includes the following steps:

[0043] (1) Sandblasting is carried out on the welding surface of the tantalum target, and then the welding surface of the tantalum target is treated with tin coating; the sand grains in the sandblasting include 60# white corundum; the sandblasting The pressure is 0.55MPa; the vertical distance between the sandblasting port and the welding surface of the tantalum target in the sandblasting treatment is 90mm; the time of the sandblasting treatment is 2.5min; after the sandblasting treatment, the tantalum target is welded The roughness of the surface is Ra2.5 μm; the thickness of the tin film in the tin plating film treatment is 5.5 μm;

[0044] (2) Copper-plated film treatment is performed on the welding surface of the back plate, and then the tin-plated tantalum target and the copper-plated back plate are heat-treated, and then the mixed metal ...

Embodiment 2

[0048] This embodiment provides a welding method for a tantalum target assembly, and the welding method includes the following steps:

[0049] (1) Sandblasting is carried out on the welding surface of the tantalum target, and then the welding surface of the tantalum target is treated with tin coating; the sand grains in the sandblasting include 60# white corundum; the sandblasting The pressure is 0.5MPa; the vertical distance between the sandblasting port and the welding surface of the tantalum target in the sandblasting treatment is 100mm; the time of the sandblasting treatment is 1min; after the sandblasting treatment, the welding surface of the tantalum target is The roughness is Ra1 μm; the thickness of the tin film in the tin coating treatment is 6 μm;

[0050] (2) Copper-plated film treatment is performed on the welding surface of the back plate, and then the tin-plated tantalum target and the copper-plated back plate are heat-treated, and then the mixed metal powder is ...

Embodiment 3

[0054] This embodiment provides a welding method for a tantalum target assembly, and the welding method includes the following steps:

[0055] (1) Sandblasting is carried out on the welding surface of the tantalum target, and then the welding surface of the tantalum target is treated with tin coating; the sand grains in the sandblasting include 60# white corundum; the sandblasting The pressure is 0.6MPa; the vertical distance between the sandblasting port and the welding surface of the tantalum target in the sandblasting treatment is 80mm; the time of the sandblasting treatment is 4min; after the sandblasting treatment, the welding surface of the tantalum target is The roughness is Ra4μm; the thickness of the tin film in the tin coating treatment is 5μm;

[0056] (2) Copper-plated film treatment is performed on the welding surface of the back plate, and then the tin-plated tantalum target and the copper-plated back plate are heat-treated, and then the mixed metal powder is res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com