Polymer insulation material for carbon brush holder and preparation method thereof

A technology of insulating materials and polymers, applied in the field of polymer insulating materials for carbon brush holders and its preparation, can solve problems such as poor performance, short service life, and easy failures, and achieve enhanced wear resistance and wear resistance Good, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

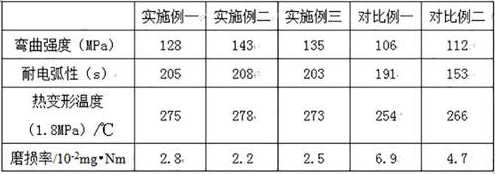

Examples

Embodiment 1

[0020] Among them, the modified glass fiber is prepared by the following method: (1) According to the mass ratio of 1:5.5, add aluminum magnesium silicate and water to stir and disperse evenly to obtain a dispersion liquid; (2) Add glass fiber and hexagonal boron nitride to the dispersion In the solution, after stirring and pre-dispersing, add methyl silicone oil and grind and mix for 2 hours to obtain a suspension. The mass ratio of glass fiber, hexagonal boron nitride, dispersion liquid and methyl silicone oil is 8:1:18:2; (3 ) according to the mass ratio of 40:4:1, mix the suspension with dioctyl maleate and 3-(methacryloyloxy)propyltrimethoxysilane, stir and mix for 20min at a speed of 800r / min, and then Put it in a vacuum oven at 68°C, dry it, and crush it to get the modified glass fiber.

[0021] The present invention also proposes a method for preparing a polymer insulating material for a carbon brush holder, comprising the following steps:

[0022] S1. Add the modifie...

Embodiment 2

[0025] A polymer insulating material for carbon brush holder proposed by the present invention comprises the following raw materials in parts by weight: 65 parts of phenolic resin, 20 parts of polyether ether ketone, 24 parts of modified glass fiber, 8 parts of terpene resin, ethylene glycol 6 parts of dimethacrylate, 7 parts of 4-hydroxybenzenesulfonic acid;

[0026] Among them, the modified glass fiber is prepared by the following method: (1) According to the mass ratio of 1:6.5, add aluminum magnesium silicate and water to stir and disperse evenly to obtain a dispersion liquid; (2) Add glass fiber and hexagonal boron nitride to the dispersion In the solution, after stirring and pre-dispersing, add methyl silicone oil for grinding and mixing for 2.5h to obtain a suspension, the mass ratio of glass fiber, hexagonal boron nitride, dispersion liquid and methyl silicone oil is 9.5:1:21:3; ( 3) According to the mass ratio of 45:5.5:2, mix the suspension with dioctyl maleate and 3...

Embodiment 3

[0031] A kind of polymer insulating material for carbon brush frame proposed by the present invention comprises the following raw materials in parts by weight: 70 parts of phenolic resin, 25 parts of polyether ether ketone, 28 parts of modified glass fiber, 12 parts of terpene resin, ethylene glycol 7 parts of dimethacrylate, 8 parts of 4-hydroxybenzenesulfonic acid;

[0032] Among them, the modified glass fiber is prepared by the following method: (1) According to the mass ratio of 1:7.5, add aluminum magnesium silicate and water to stir and disperse evenly to obtain a dispersion liquid; (2) Add glass fiber and hexagonal boron nitride to the dispersion In the solution, after stirring and pre-dispersing, add methyl silicone oil for grinding and mixing for 3 hours to obtain a suspension, the mass ratio of glass fiber, hexagonal boron nitride, dispersion liquid and methyl silicone oil is 11:1:24:4; (3 ) According to the mass ratio of 50:7:3, mix the suspension with dioctyl malea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com