A uniformly modified silicon-based composite material and its preparation method and application

A silicon-based composite material and modification technology, applied in the field of materials, can solve problems such as changing surface conductivity, achieve the effect of improving fast charging performance and bulk phase conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

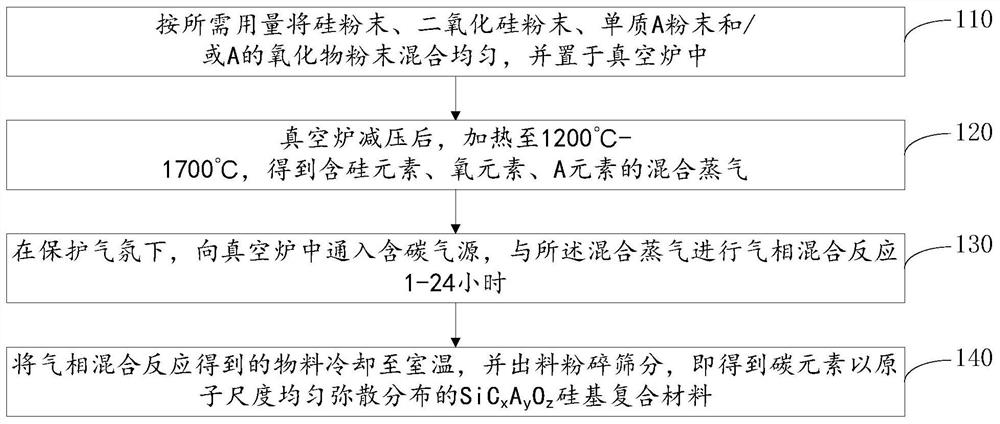

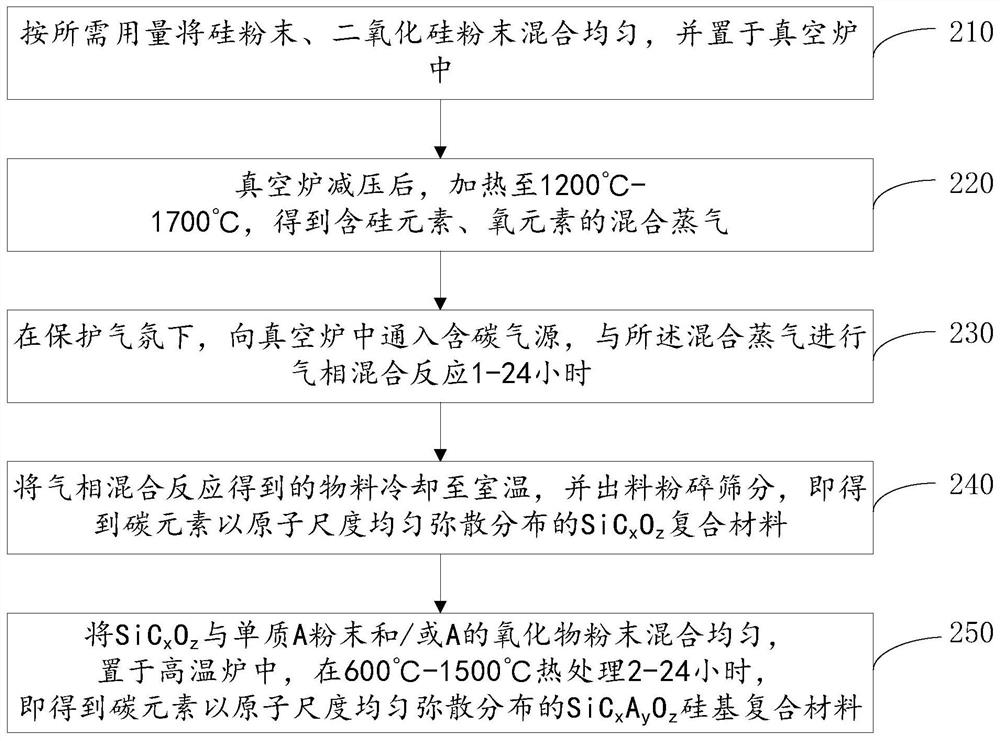

Method used

Image

Examples

Embodiment 1

[0061] Put 1kg of silicon powder, 1kg of silicon dioxide and 0.3kg of copper oxide mixed powder in a high-temperature reaction furnace, evacuate to 50Pa, and heat up to 1500°C to become steam. 1.6 L of methane was slowly introduced into the mixture under argon flow for 3 hours, and then cooled to room temperature. After discharging and pulverizing, a silicon-based composite material in which internal carbon and copper elements are evenly dispersed at the atomic level can be obtained. The carbon content is 1.5% when tested with a carbon-sulfur analyzer.

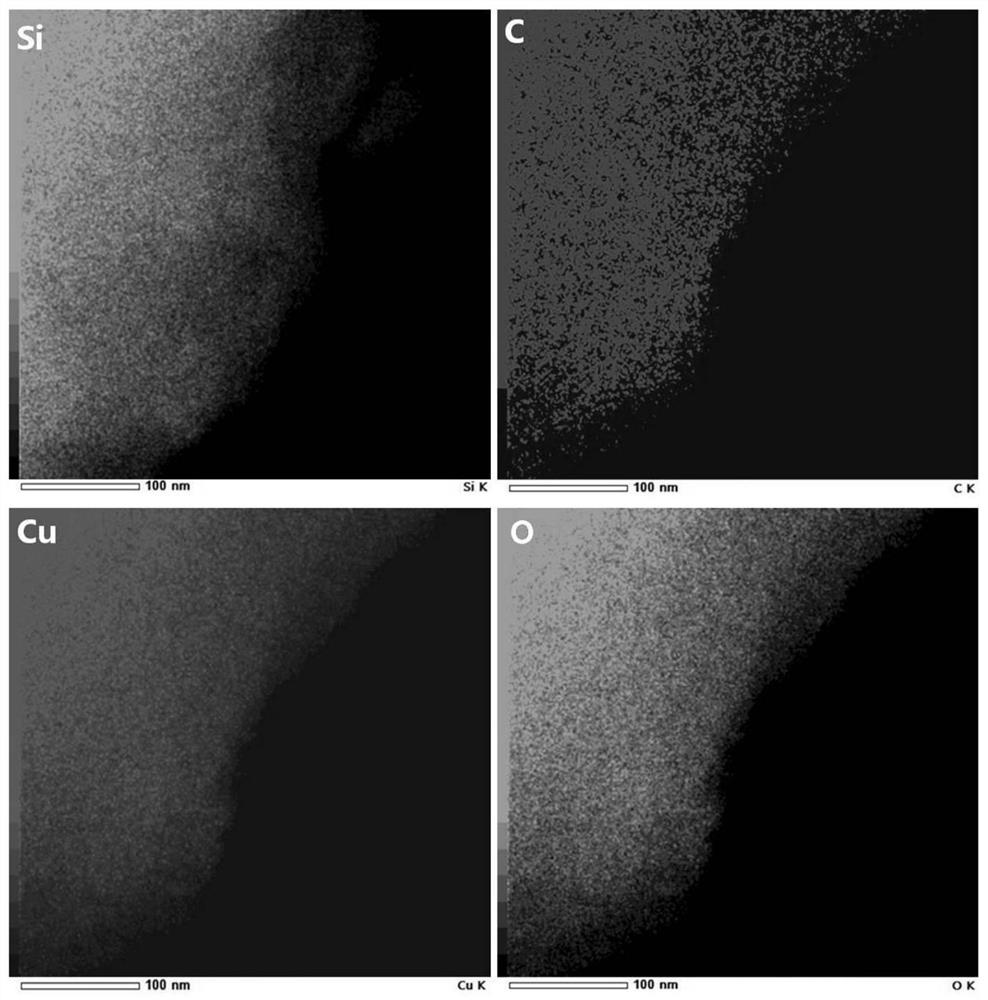

[0062] The obtained silicon-based composite material was tested by FIB-TEM, and the distribution of elements inside the particles was observed by energy spectrum detection. image 3 It is a surface scan of FIB-TEM energy spectrum. From figure 2 The energy spectrum element scan shows that the four elements Si, C, Cu and O are evenly distributed in the particles.

[0063] Afterwards, carry out carbon coating on the silicon-...

Embodiment 2

[0067] Put 1kg of silicon powder and 1kg of silicon dioxide mixed powder in a vacuum furnace, evacuate to 50Pa, heat up to 1500°C and turn into steam. Subsequently, 1.6 L of methane was slowly introduced into the mixture under an argon flow for 3 hours, and cooled to room temperature. After the material is discharged and pulverized, the silicon-based material powder in which the internal carbon element is uniformly dispersed at the atomic level is obtained. The carbon content is 1.8% when tested with a carbon-sulfur analyzer.

[0068] Mix the obtained silicon-based material powder with internal carbon uniformly dispersed at the atomic level and copper oxide at a molar ratio of 1:0.4, and then heat-treat at 1000°C for 4 hours to obtain a silicon-based composite containing internal carbon and copper elements. Material.

[0069] The above materials are then carbon coated. Put 2kg of silicon-based composite material in a rotary furnace and raise the temperature to 1000°C under ...

Embodiment 3

[0072] Put 3kg of silicon powder, 3kg of silicon dioxide, and 1kg of boron oxide mixed powder in a vacuum furnace, evacuate to 100Pa, heat up to 1350°C to become a vapor, and slowly feed 23.4L of propane under an argon flow to react8 hours, cooled to room temperature. After the material is discharged and pulverized, the silicon-based composite material in which the internal carbon and boron elements are evenly dispersed at the atomic level can be obtained. The carbon content is 2.0% when tested with a carbon-sulfur analyzer.

[0073] Afterwards, carbon-coated it, put 2kg of material in a rotary furnace, and raised the temperature to 900°C under the protective gas of argon, and introduced argon and a mixed gas of propylene and methane in the same amount as argon at a volume ratio of 1:1. Gas-phase coating was carried out in which the volume ratio of propylene and methane was 2:3. After heat preservation for 3 hours, the organic gas source was turned off, and after the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com