Metal slurry, heating circuit, atomizing core, preparation method of atomizing core, and electronic cigarette

A technology of metal paste and heating circuit, which is applied in the field of electronic cigarettes, can solve the problems of brittle ceramic substrate, phase separation, falling off of heating circuit, etc., to ensure continuity, ensure stability of resistance value, and reduce error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

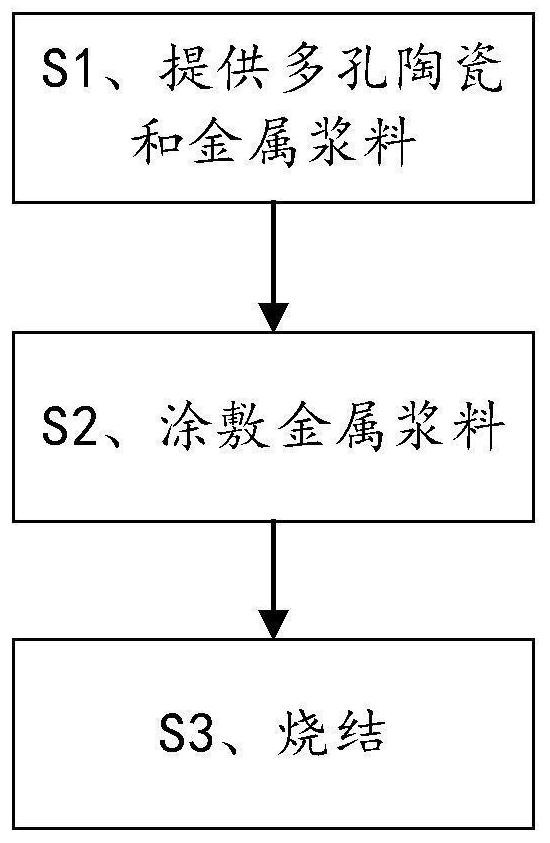

[0034] Such as figure 1 As shown, this embodiment also provides a method for preparing the atomizing core, which includes the following steps:

[0035] S1. Providing porous ceramics and metal pastes: respectively providing porous ceramics and metal pastes, wherein the porous ceramics are the above-mentioned porous ceramics, and the metal pastes are the above-mentioned metal pastes.

[0036] S1.1. Preparation of porous ceramics: In order to arrange the pores of the porous ceramics in an orderly manner and to ensure the inclination angle between the axial direction of the pores of the porous ceramics and the atomization surface, the porous ceramics can be prepared by a template method. Taking the preparation of zirconia porous ceramics as an example, the preparation of the porous ceramics includes the following steps:

[0037]Adding 1 part of the polymer to 4-6 parts of the binary system organic solvent, dissolving under the condition of avoiding light, and mixing uniformly to ...

Embodiment 1

[0048] Embodiment 1: For the atomizing core of this embodiment, the mass ratio of metal powder, glass powder and organic vehicle in the metal paste is 100:10:20.

[0049] Among them, every 100 parts by mass of metal powder includes 20 parts of Ni powder, 15 parts of Cr powder and 65 parts of NiCr 20 Alloy powder. Among them, the median particle size D50 of Ni powder = 9.8 μm, the median particle size D50 of Cr powder = 9.6 μm, NiCr 20 The median particle size D50 of the alloy powder is 30 μm.

[0050] Every 100 parts by mass of the glass powder includes 40 parts of Si, 20 parts of Al, 10 parts of B, and 30 parts of other components. The median particle size D50 of the glass powder is 20 μm. In the organic vehicle, the mass ratio of ethyl cellulose to the terpineol is 30:70.

[0051] The porosity of the porous ceramic is 50%, the pore diameter is 30 μm, and the thickness of the prepared heating circuit is 50 μm.

Embodiment 2

[0052] Embodiment 2: The metal paste of the atomizing core in this embodiment is basically the same as the metal paste in Embodiment 1, the difference is that every 100 parts by mass of the glass frit includes 42 parts of Si, 19 parts of Al, 10 parts of B, and 29 parts for the remaining components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com