Carbon fiber grounding electrode

A grounding electrode and carbon fiber technology, applied in the direction of connecting contact materials, etc., can solve the problems of difficult installation and construction, bulky products, high brittleness, etc., and achieve the effect of wide application range, improved corrosion resistance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

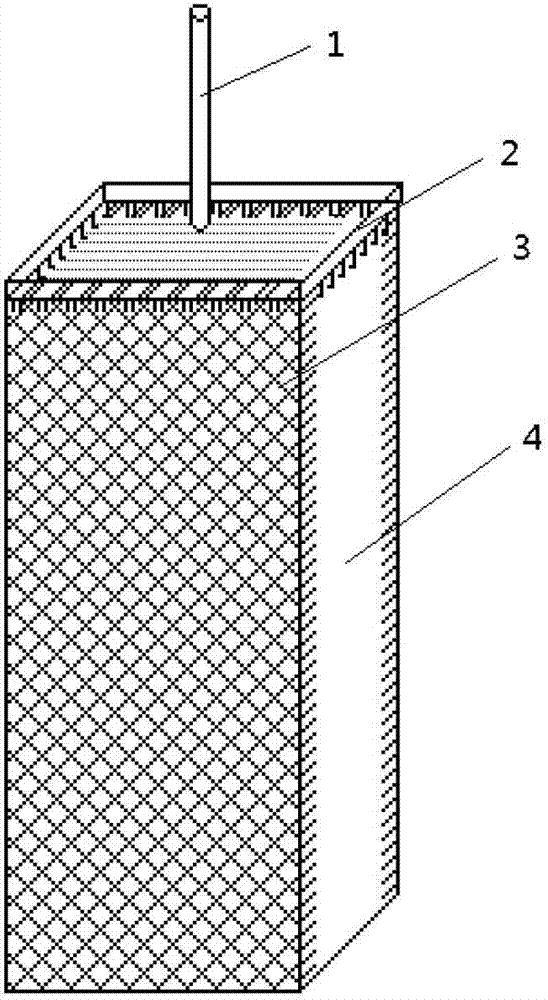

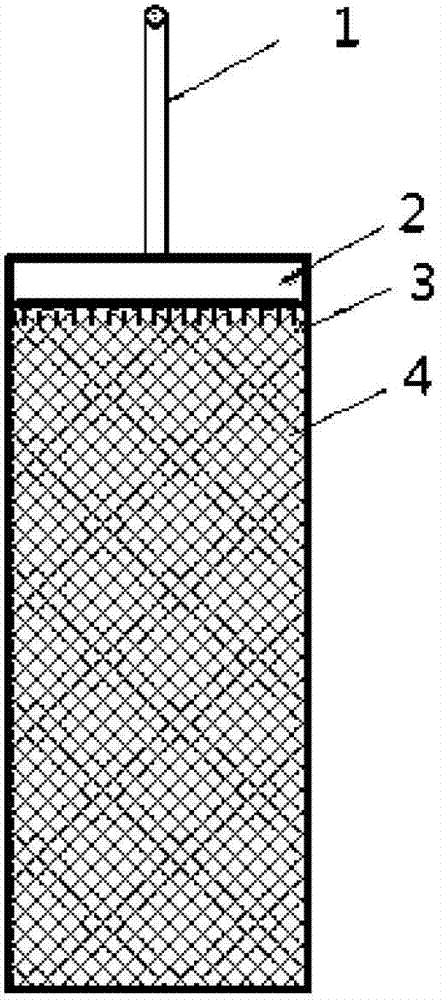

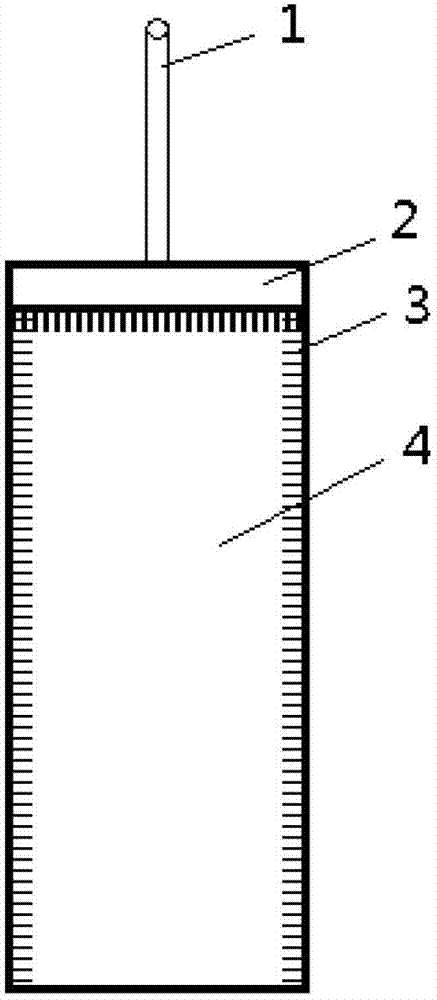

[0024] Figure 1-Figure 5 Among them, the carbon fiber felt is the carbon fiber mandrel 4, and the copper mesh is the coated metal mesh 3. The specific examples of producing the carbon fiber grounding electrode of the present invention are as follows:

[0025] It is formed by needle punching of polyacrylonitrile-based chopped strands and carbonized at 1400°C to make felt; the thickness is 10mm and the bulk density is 0.9g / cm 3 The carbon fiber felt is used as the carbon fiber mandrel 4; the 30-mesh barbed copper wire mesh is molded and inlaid into the surface of the carbon fiber felt electrode, the depth of the copper mesh needle is 2mm, and the surface density of the needle is 4 needles / cm 2 ;The electrode 2 drawn out by the copper plate is hooked with the end of the carbon fiber felt, the depth of the hook is 2mm, and the density of the hook surface is 6 needles / cm 2 The copper wire lead-out line 1 and the copper plate lead-out electrode 2 are welded and fixed, and the copp...

Embodiment 2

[0027] With the graphite fiber felt as the carbon fiber mandrel 4, and the aluminum mesh as the coated metal mesh 3, the specific examples of producing the carbon fiber grounding electrode of the present invention are as follows:

[0028] Using polyacrylonitrile-based carbon fiber felt carbonized at 1400°C as raw material, it is made into high-purity graphite fiber felt through high-vacuum graphitization treatment at 2350°C; the thickness is 20mm and the bulk density is 0.7g / cm 3 The graphite fiber felt is used as the carbon fiber mandrel 4; 40-mesh barbed aluminum wire mesh is molded and inlaid into the electrode surface of the graphite fiber felt, the penetration depth of the aluminum mesh needle is 3mm, and the surface density of the needle is 6 needles / cm 2 ;Use the aluminum plate to lead out the electrode 2 hooks and combine with the end of the graphite fiber felt, the depth of the hooks is 3mm, and the density of the hooks is 8 needles / cm 2 The aluminum wire lead-out lin...

Embodiment 3

[0030] With the carbon fiber two-dimensional semi-woven body as the carbon fiber mandrel 4, and the molybdenum wire mesh as the coated metal mesh 3, the specific examples of producing the carbon fiber grounding electrode of the present invention are as follows:

[0031] Using 3K Japanese Toray T300 carbon fiber as raw material, it is formed by two-dimensional semi-weaving process to prepare carbon fiber multi-dimensional weaving body; the thickness is 15mm and the density is 0.6g / cm 3 The carbon fiber two-dimensional semi-braided body is used as the carbon fiber mandrel 4; the electrode surface of the carbon fiber two-dimensional semi-braided body is pierced with a 40-mesh barbed molybdenum wire mesh molded mosaic, the penetration depth of the molybdenum mesh needle is 2mm, and the needle surface density is 6 needles / cm 2 ;Using the molybdenum plate to lead out the electrode 2 hooks and the end of the carbon fiber two-dimensional semi-braided body, the depth of the hooks is 3mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com