A kind of superelastic fatigue-resistant foaming material and its preparation method and application

A foamed material and fatigue-resistant technology, applied in the field of foam manufacturing, can solve problems such as unsatisfactory fatigue-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

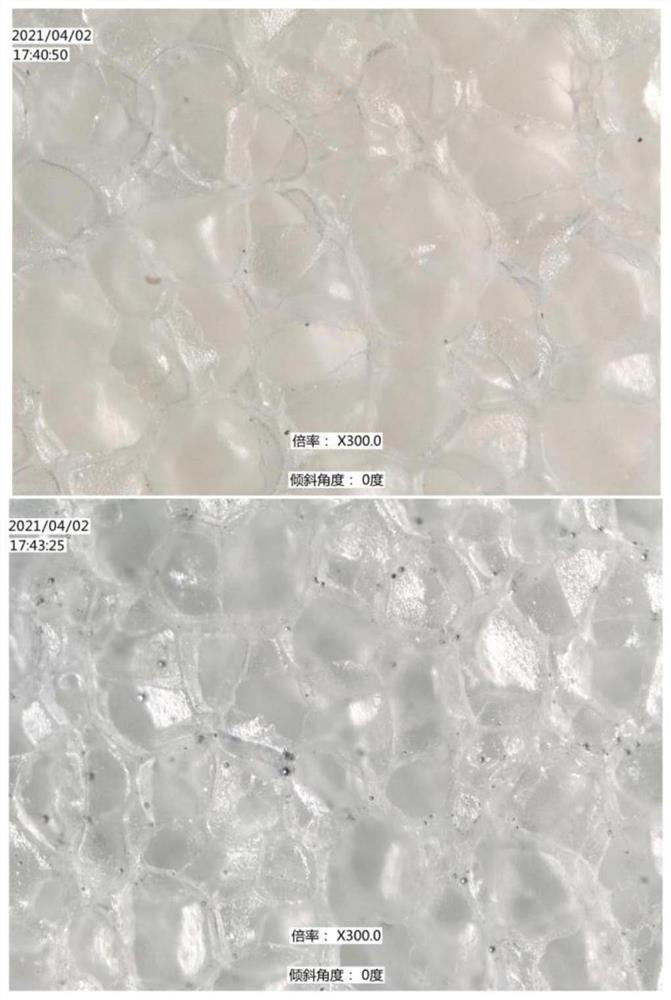

Image

Examples

preparation example Construction

[0038] The present invention provides a preparation method of the superelastic fatigue-resistant foam material described in the above technical solution, comprising the following steps:

[0039] a) After premixing 100 parts of thermoplastic elastomer resin, 0.5-50 parts of amorphous metal powder, 0.2-1 part of antioxidant, 0-1.5 part of stearic acid and 0-1 part of cell stabilizer, melt mixing Smelting, extruding and dicing to obtain thermoplastic elastomer composite particles;

[0040] b) After preheating the thermoplastic elastomer composite particles obtained in the step a), they are loaded into a mold for clamping, placed in a closed container, and gas is introduced into the container, and the temperature is increased, so that the gas that has reached a supercritical state affects all The thermoplastic elastomer composite particles are impregnated and saturated, and finally the pressure is quickly released and the mold is opened to obtain a superelastic fatigue-resistant f...

Embodiment 1

[0059] (1) The formula composition of thermoplastic elastomer composite material:

[0060] Thermoplastic polyurethane (TPU): 100 parts by weight;

[0061] Amorphous metal alloy powder: 5 parts by weight;

[0062] Antioxidant: 0.3 parts by weight;

[0063] Stearic acid: 0.5 parts by weight;

[0064] Cell stabilizer: 0.5 parts by weight;

[0065] Among them, the amorphous metal alloy powder is nickel-titanium alloy (nickel and titanium each account for 50%); the antioxidant is AT-10; the cell stabilizer is polyisobutyl methacrylate.

[0066] (2) Preparation method:

[0067] Weigh each component in the above thermoplastic elastomer composite material by weight as raw materials; the weighed raw materials are pre-mixed and then melted and kneaded at 200 ° C for 5 minutes by an extruder, and then extruded in water at 25 ° C. Pellet down to obtain thermoplastic elastomer composite particles; then preheat the obtained thermoplastic elastomer composite particles to 100 ° C, pour it ...

Embodiment 2

[0071] (1) The formula composition of thermoplastic elastomer composite material:

[0072] Thermoplastic polyester elastomer (TPEE): 100 parts by weight;

[0073] Amorphous metal alloy powder: 5 parts by weight;

[0074] Antioxidant: 0.3 parts by weight;

[0075] Stearic acid: 0.5 parts by weight;

[0076] Cell stabilizer: 0.5 parts by weight;

[0077] Among them, the amorphous metal alloy powder is an iron-based alloy (Fe 60%, Ni15%, Cr 18%, B 4%, other 3%); the antioxidant is AT-10; the nucleating agent is nano-titanium dioxide; the cell is stable The agent is polyisobutyl methacrylate.

[0078] (2) Preparation method:

[0079] Weigh each component in the above thermoplastic elastomer composite material by weight as raw materials; the weighed raw materials are premixed and then melted and kneaded at 195 ℃ for 5 minutes by an extruder, and then extruded in water at 25 ℃. Cut the pellets down to obtain thermoplastic elastomer composite particles; then preheat the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com