A kind of biodegradable foam shoe midsole material and preparation method thereof

A biological and material technology, applied in the field of shoe manufacturing, can solve the problems of reduced biodegradable properties, long process, thermal degradation of materials, etc., and achieve the effect of good interaction, short process, and ultra-light density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

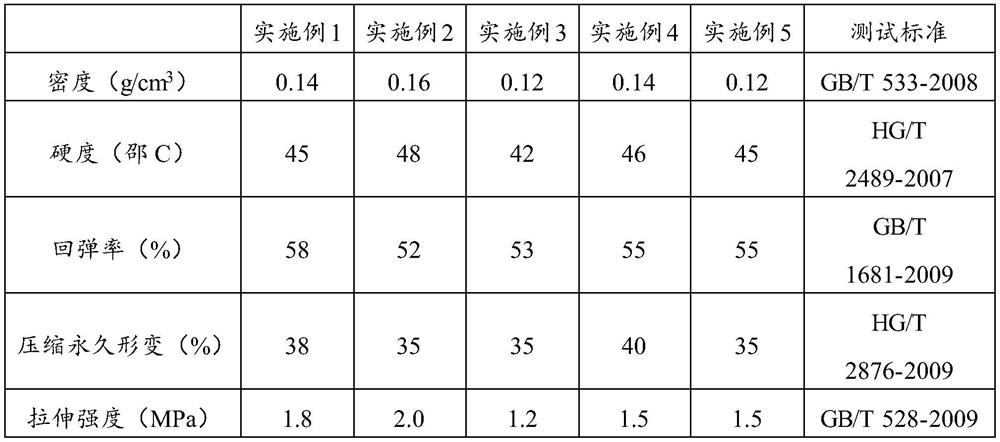

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing the biodegradable foam shoe midsole material described in the above technical solution, comprising the following steps:

[0045] a) After premixing the components in the biodegradable resin material, performing melt mixing, extruding and then cutting into pellets to obtain biodegradable material particles;

[0046] b) Preheat the biodegradable material particles obtained in step a), put them into a mold and close them, place them in an airtight container, and pass gas into the container to raise the temperature, so that the gas that has reached a supercritical state is harmful to the biodegradable material. The degraded material particles are impregnated and saturated, and finally the pressure is released quickly and the mold is opened to obtain the biodegradable foam shoe midsole material.

[0047] In the invention, firstly, the components in the biodegradable resin material are premixed, melted and kneaded, ex...

Embodiment 1

[0062] (1) Formulation of biodegradable resin materials:

[0063] Polyadipate / butylene terephthalate (PBAT): 100 parts by weight;

[0064] Masterbatch: 1 part by weight

[0065] Antioxidant: 0.3 parts by weight;

[0066] Nucleating agent: 5 parts by weight;

[0067] Stearic acid: 0.5 parts by weight;

[0068] Cell stabilizer: 0.5 parts by weight;

[0069]Among them, the masterbatch is made by blending white toner and PBAT; the antioxidant is AT-10; the nucleating agent is nano-titanium dioxide; the cell stabilizer is polyisobutyl methacrylate.

[0070] (2) Preparation method:

[0071] Weigh each component of the above-mentioned biodegradable resin material in parts by weight as a raw material; pre-mix the weighed raw materials, melt and knead them at 160°C for 3min through an extruder, and heat them in water at 25°C after extrusion. Cut into pellets to obtain biodegradable material particles; then preheat the obtained biodegradable material particles to 80°C, pour them i...

Embodiment 2

[0073] (1) Formulation of biodegradable resin materials:

[0074] 3-hydroxybutyrate-3-hydroxyvalerate copolymer (PHBV): 100 parts by weight;

[0075] Masterbatch: 1 part by weight

[0076] Antioxidant: 0.3 parts by weight;

[0077] Nucleating agent: 5 parts by weight;

[0078] Stearic acid: 0.5 parts by weight;

[0079] Cell stabilizer: 0.5 parts by weight;

[0080] Among them, the masterbatch is made by blending white toner and PHBV; the antioxidant is AT-10; the nucleating agent is nano-titanium dioxide; the cell stabilizer is polyisobutyl methacrylate.

[0081] (2) Preparation method:

[0082] Weigh each component in the above-mentioned biodegradable resin material in parts by weight as a raw material; pre-mix the weighed raw materials, melt and knead them at 175°C for 3 minutes through an extruder, Down pelletizing to obtain biodegradable material particles; then preheat the obtained biodegradable material particles to 100°C, pour them into a midsole mold that is als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com