Matte insulating polyimide black film and preparation method thereof

A technology of polyimide and polyimide powder, which is applied in the field of matte insulating polyimide black film and its preparation, can solve the problems of limited effect, poor compatibility between carbon black and polyimide system, etc. Achieve performance improvement, good appearance, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

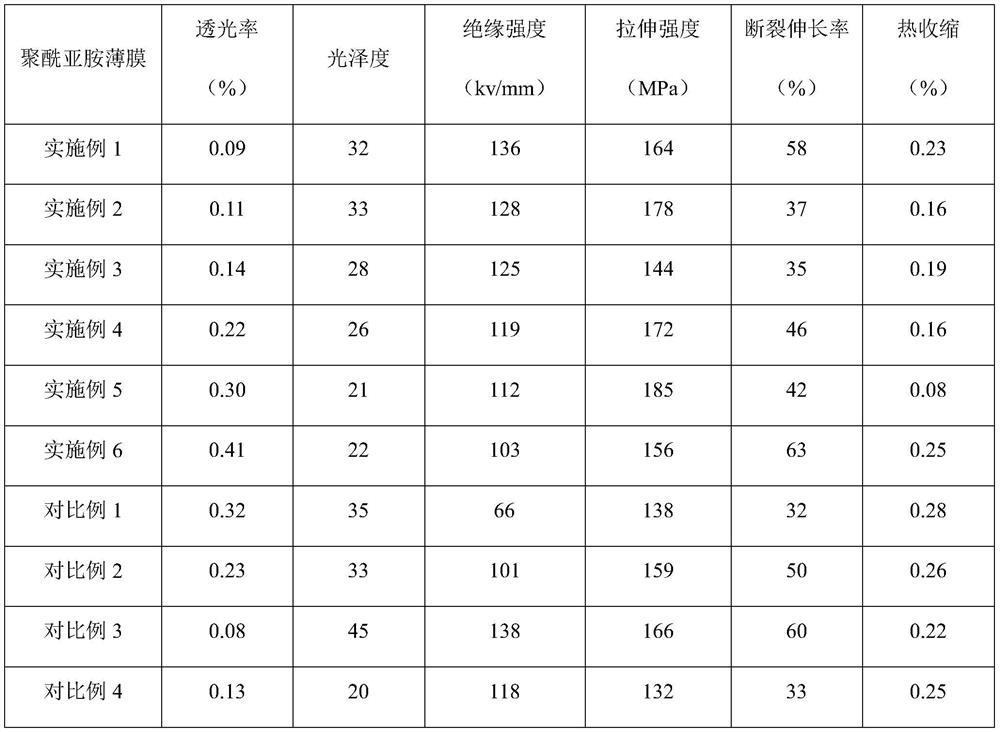

Examples

Embodiment 1

[0046] Preparation of silane coupling agent modified polyimide powder:

[0047] (a), under a nitrogen atmosphere, dissolve 0.5mol ODA in a DMF solvent, then add 0.525mol PMDA, stir and react at 20°C for 3h, to obtain a polyamic acid solution with a solid content of 1%wt and excess anhydride;

[0048] (b) Add 0.1mol N-β-(aminoethyl)-γ-aminopropyl-trimethoxysilane to the polyamic acid solution with excess anhydride, stir and react at 60°C for 12h, then add 1mol ethyl Anhydride and 0.75mol isoquinoline were stirred and reacted at 80°C for 12h. After the reaction was completed, the reaction system was kept at 130°C for 10h, cooled, filtered, and the obtained solid matter was washed 3 times with ethanol solution and dried in vacuum Dry it in an oven at 100°C for 12 hours, and grind it to an average particle size of 3 μm.

[0049] Preparation of carbon black slurry:

[0050] Add blue phase channel carbon black with a primary particle size of 20nm into the DMF solvent, use a high-spe...

Embodiment 2

[0056] Preparation of silane coupling agent modified polyimide powder:

[0057] (a), under a nitrogen atmosphere, dissolve 0.5mol PDA in DMAc solvent, then add 0.55mol PMDA, stir and react at 25°C for 2h, to obtain a polyamic acid solution with a solid content of 1wt% and excess anhydride;

[0058] (b) Add 0.125mol N-β-(aminoethyl)-γ-aminopropyl-triethoxysilane to the polyamic acid solution with excess anhydride, stir and react at 60°C for 12h, then add 1.25 mol acetic anhydride and 1mol isoquinoline, stirred and reacted at 80°C for 12h, after the reaction was completed, the reaction system was kept at 130°C for 10h, cooled, filtered, and the obtained solid matter was washed 3 times with ethanol solution, and placed in a vacuum Dry in a drying oven at 100°C for 12 hours, and pulverize until the average particle size is 3 μm.

[0059] Preparation of carbon black slurry:

[0060] Add blue phase channel carbon black with a primary particle size of 30nm into the DMF solvent, use...

Embodiment 3

[0066] Preparation of silane coupling agent modified polyimide powder:

[0067] (a) Under a nitrogen atmosphere, dissolve 0.4mol ODA and 0.1mol PDA in NMP solvent, then add 0.55mol BPDA, stir and react at 25°C for 2h, and obtain a polyamic acid with an anhydride excess of 3wt% solid content solution;

[0068] (b) Add 0.125mol N-β-(aminoethyl)-γ-aminopropyl-methyldimethoxysilane to the polyamic acid solution with excess anhydride, stir and react at 70°C for 10h, and then Add 1.25mol acetic anhydride and 1mol isoquinoline, stir and react at 90°C for 10h, after the reaction is complete, keep the reaction system at 140°C for 8h, cool, filter, and wash the obtained solid matter with ethanol solution 3 times, place Dry it in a vacuum oven at 100°C for 12 hours, and grind it to an average particle size of 4 μm.

[0069] Preparation of carbon black slurry:

[0070] Add blue phase channel carbon black with a primary particle size of 30nm into DMAc solvent, use a high-speed shear dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com