Method for preparing bionic MOFs-based double-layer molecular imprinting nano composite membrane based on double continuous imprinting system and application of bionic MOFs-based double-layer molecular imprinting nano composite membrane

A nanocomposite and molecularly imprinted technology, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of low crystallization/nucleation efficiency, poor connection stability, etc., and achieve selective permeability and flux , Solve poor stability, solve the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

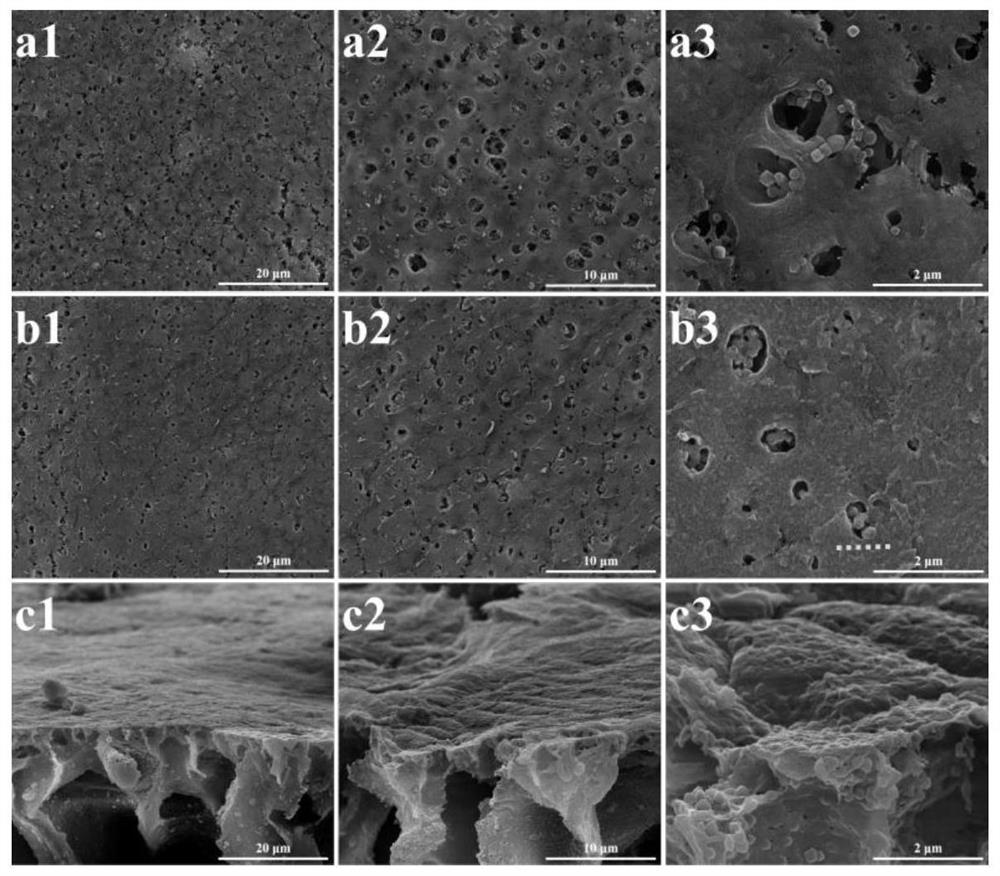

Image

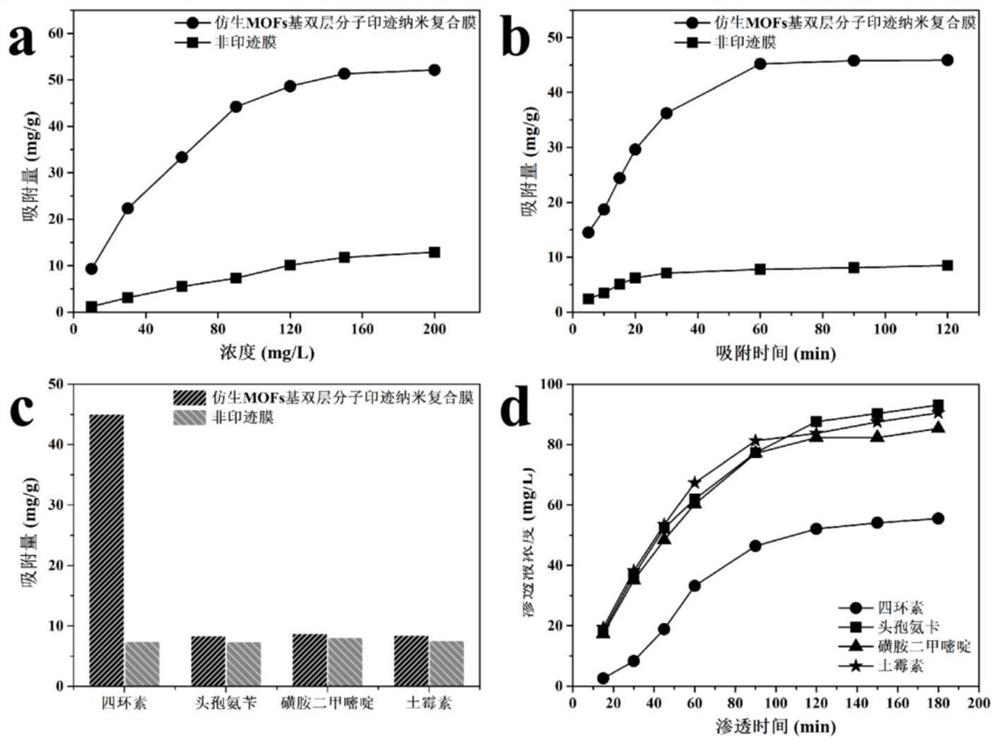

Examples

Embodiment 1

[0061] S1. Preparation of UiO-66 particles:

[0062] Dissolve 0.75g of zirconium chloride in an autoclave containing a mixed solution of 5.5mL of acetic acid and 80mL of dimethylformamide. After mixing well, add 0.53g of terephthalic acid, and ultrasonically treat the resulting mixed solution until it is completely dissolved. Finally, Add 0.24ml of deionized water and seal the autoclave; heat it at 120°C for 12h, after the reaction is over, wash the obtained solid powder with dimethylformamide and ethanol several times respectively, and add the obtained solid powder to a container containing 50ml of ethanol in a reaction kettle, and heated at 80°C for 8h, and dried the final product in a vacuum oven to obtain UiO-66 particles.

[0063] S2. Preparation of polydopamine-based imprinted UiO-66:

[0064] Dissolve 0.1211g tris(hydroxymethyl)aminomethane hydrochloride and 0.2g dopamine hydrochloride in 100mL deionized water to obtain a mixed solution, adjust the pH value of the solu...

Embodiment 2

[0085] S1. Preparation of UiO-66 particles:

[0086] Dissolve 0.75g of zirconium chloride in an autoclave containing a mixed solution of 5.5mL of acetic acid and 80mL of dimethylformamide. After mixing well, add 0.53g of terephthalic acid, and ultrasonically treat the resulting mixed solution until it is completely dissolved. Finally, Add 0.24 ml of deionized water and seal the autoclave. Heat it at 120°C for 12 hours. After the reaction, wash the obtained solid powder with dimethylformamide and ethanol several times respectively, add the obtained solid powder into a reaction kettle containing 50ml of ethanol, and heat at 80°C 8h, the final product was dried in a vacuum oven to obtain UiO-66 particles.

[0087] S2. Preparation of polydopamine-based imprinted UiO-66:

[0088] Dissolve 0.1211g tris(hydroxymethyl)aminomethane hydrochloride and 0.2g dopamine hydrochloride in 100mL deionized water to obtain a mixed solution, adjust the pH value of the solution to 8.5, add 0.5g Ui...

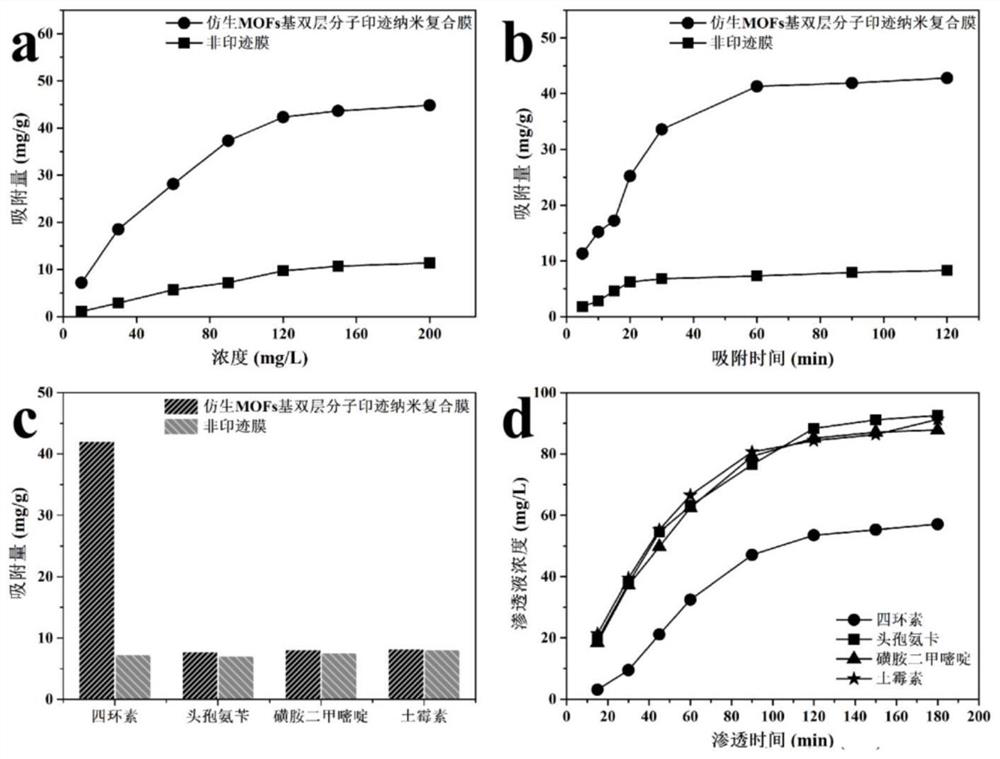

Embodiment 3

[0108] S1. Preparation of UiO-66 particles:

[0109] Dissolve 0.75g of zirconium chloride in an autoclave containing a mixed solution of 5.5mL of acetic acid and 80mL of dimethylformamide. After mixing well, add 0.53g of terephthalic acid, and ultrasonically treat the resulting mixed solution until it is completely dissolved. Finally, Add 0.24 ml of deionized water and seal the autoclave. Heat it at 120°C for 12 hours. After the reaction, wash the obtained solid powder with dimethylformamide and ethanol several times respectively, add the obtained solid powder into a reaction kettle containing 50ml of ethanol, and heat at 80°C 8h, the final product was dried in a vacuum oven to obtain UiO-66 particles.

[0110] S2. Preparation of polydopamine-based imprinted UiO-66:

[0111] Dissolve 0.1211g tris(hydroxymethyl)aminomethane hydrochloride and 0.2g dopamine hydrochloride in 100mL deionized water to obtain a mixed solution, adjust the pH value of the solution to 8.5, add 0.5g Ui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com